Hydraulic cold drawing machine die

A cold drawing machine and hydraulic technology, applied in the direction of wire drawing dies, etc., can solve the problems of complex adjustment of inner dies and difficulty in ensuring ellipticity, and achieve the effects of reducing costs, simplifying die adjustment procedures, and improving production efficiency and product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

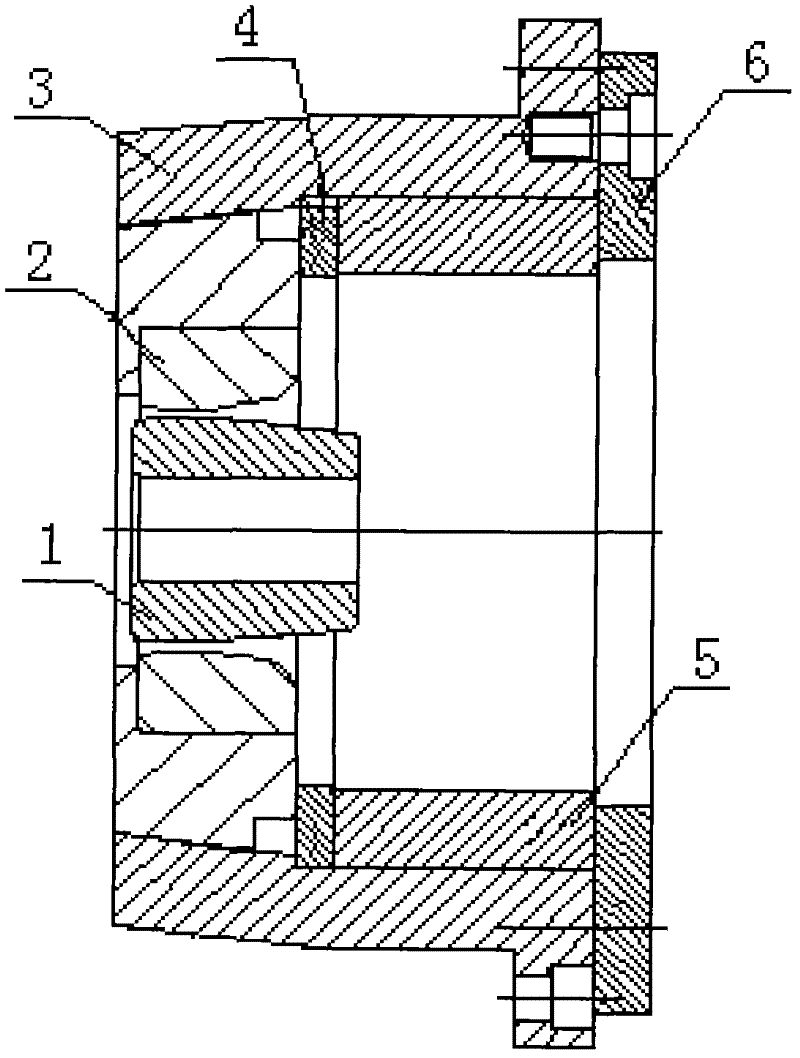

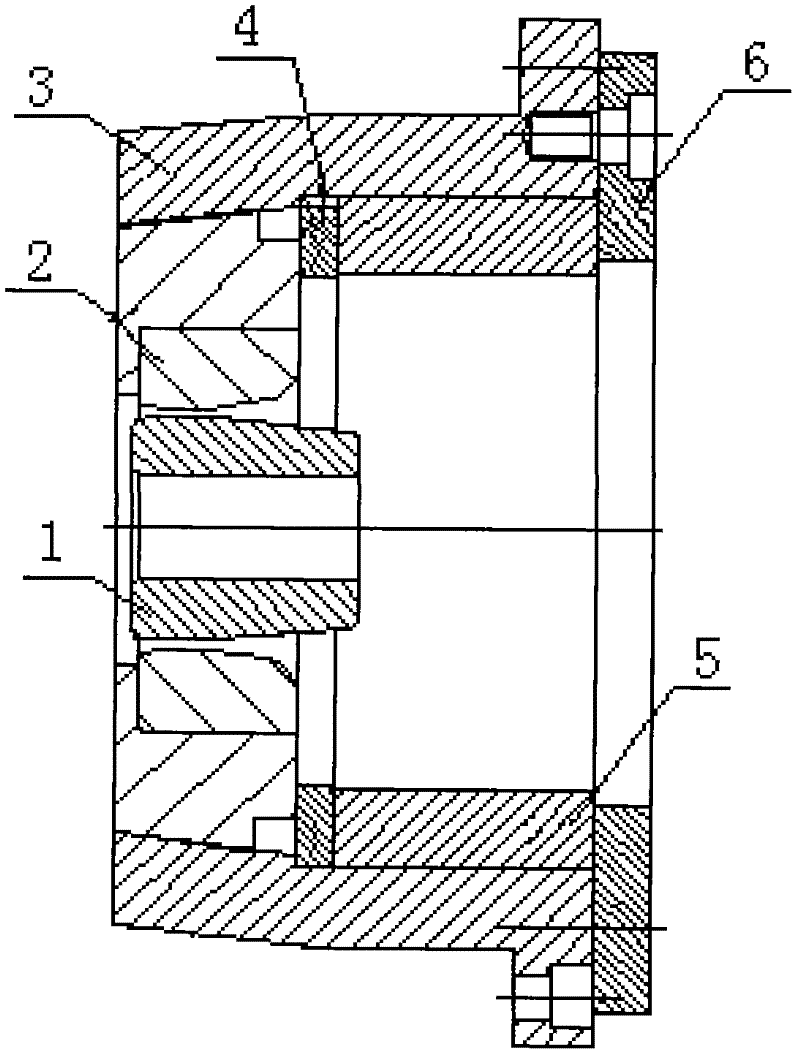

[0012] Such as figure 1 As shown, a specific embodiment of the present invention is provided. In the figure, a hydraulic cold drawing machine mold includes an inner mold 1, an outer mold 2, an outer mold cover 3, a backing plate 4, a pressure ring 5 and an outer mold pressing Cover 6, the size of the sizing belt of the inner mold 1 and the outer mold 2 is 20mm to 30mm shorter than the commonly used standard. In order to ensure the tight installation of the inner mold 1 and the outer mold 2, a backing plate 4 is added under the pressure ring 5 , its thickness is equivalent to the shortened size of the sizing belt, and the outer mold gland 6 is fastened and installed outside the pressure ring 5 .

[0013] In terms of material selection, the present invention adopts high-carbon and high-chromium cold work die steel Cr12MoV with high hardenability to replace the original high-carbon chromium bearing steel GCr15, so that the mold has higher hardness, good wear resistance and Highe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com