Split type deflector

A director and split-type technology, applied in non-variable-capacity pumps, radial flow pumps, non-displacement pumps, etc., can solve the problems of greatly increased manufacturing and operating costs, uneconomical, complicated processes, etc., to ensure Effects of dynamic balance accuracy and runout inspection accuracy, reduced manufacturing and operating costs, and simplified adjustment procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

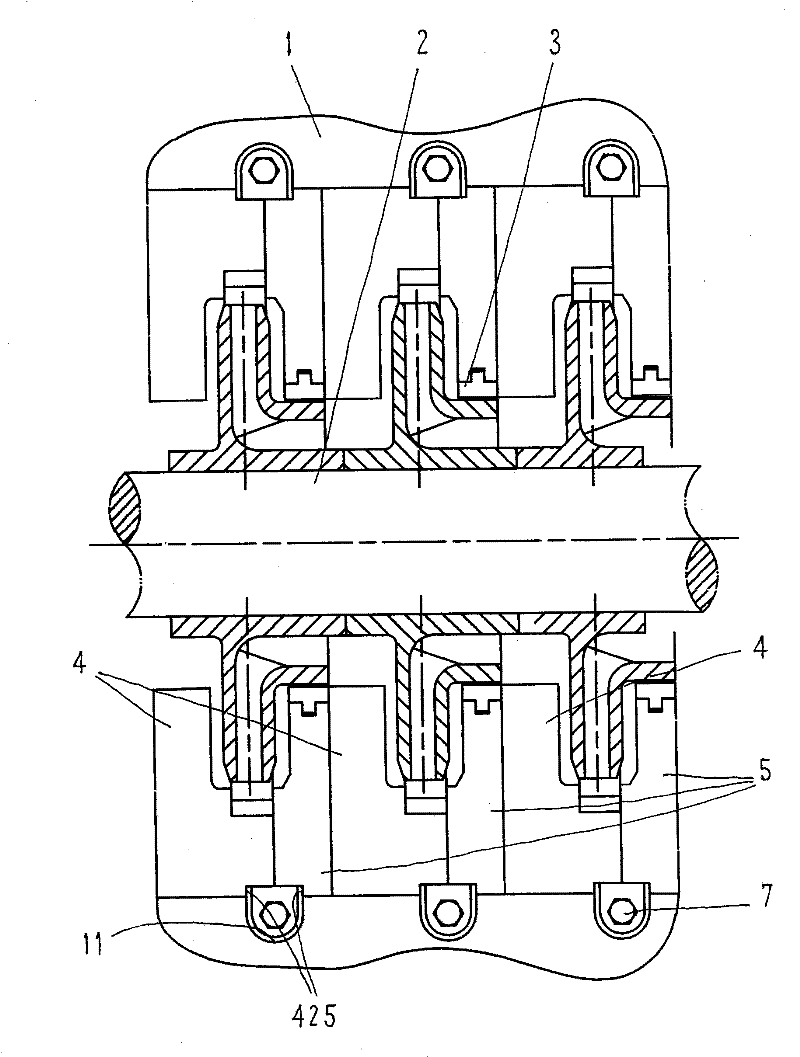

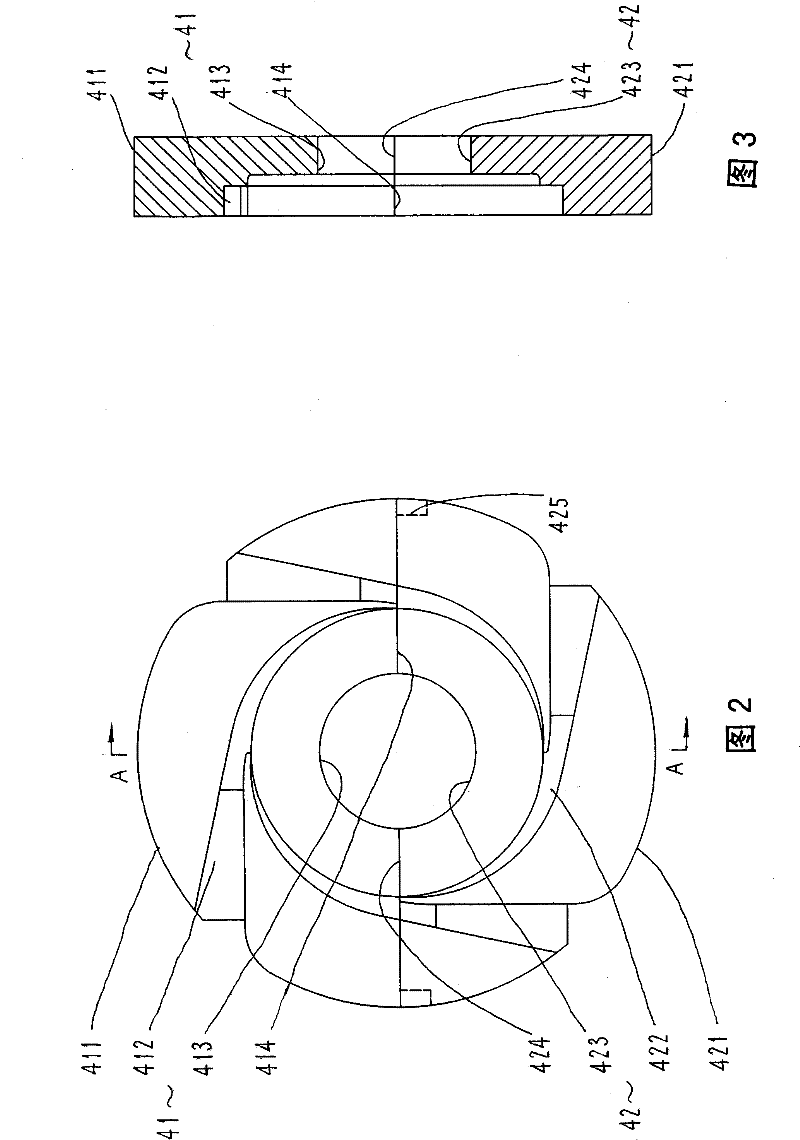

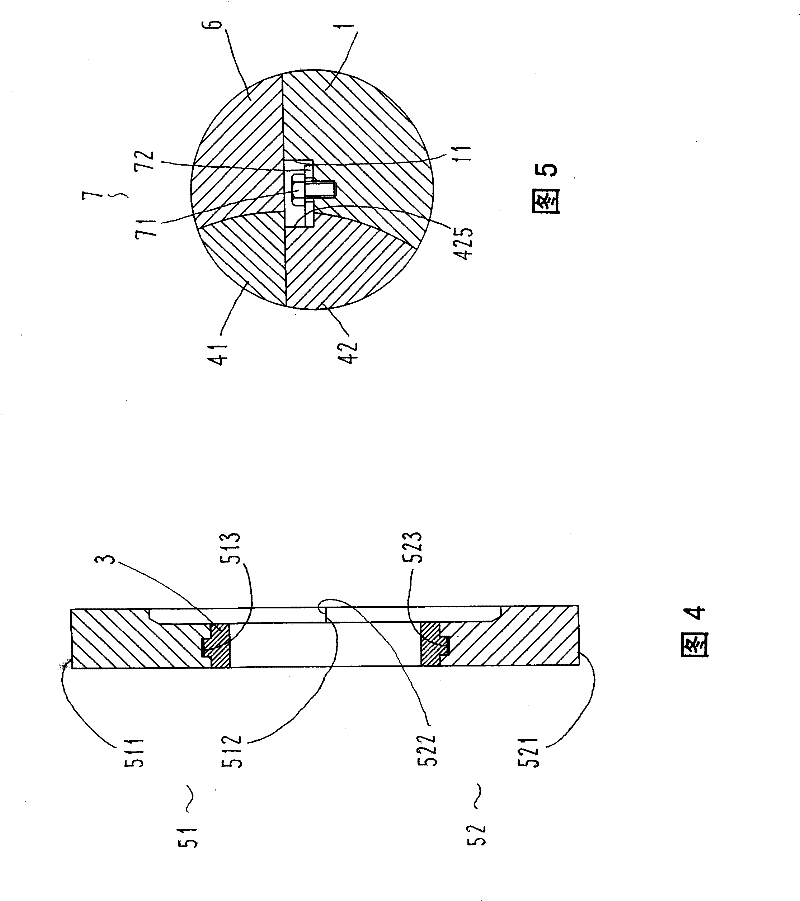

[0017] refer to figure 1 , shows a schematic diagram of a longitudinal section of a three-stage water pump, that is, a section view along the split plane of the split pump body and pump cover. The device assembly 4, the diaphragm assembly 5, the circumferential positioning assembly 7 (the pump cover 6 is cut off from the figure), the pump body 1, the impeller assembly 2, the sealing ring 3, and the pump cover 6 are all the same or similar to the prior art, and the sealing The ring can also adopt a split structure. guide assembly 4, figure 1 The number of guider assemblies 4 shown corresponds to 3 pieces corresponding to the impeller assembly 2, and each guider assembly 4 has the same structure, and each guider assembly 4 is composed of an upper guider body 41 and a lower guider body 42 and is divided into two parts. Type structure, the hydrodynamic performance of the two-piece guide assembly 4 is the same as that of the existing integral guide; wherein:

[0018] Upper guide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com