Evaporator

An evaporator and the same technology, applied in the field of micro-tube evaporators, can solve the problems of mass flow distribution micro-tube evaporator performance degradation, uneven mass flow distribution of water chamber, high air side pressure drop, etc., to achieve uniform refrigerant distribution, Uniform flow and temperature distribution, easy installation and fixation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

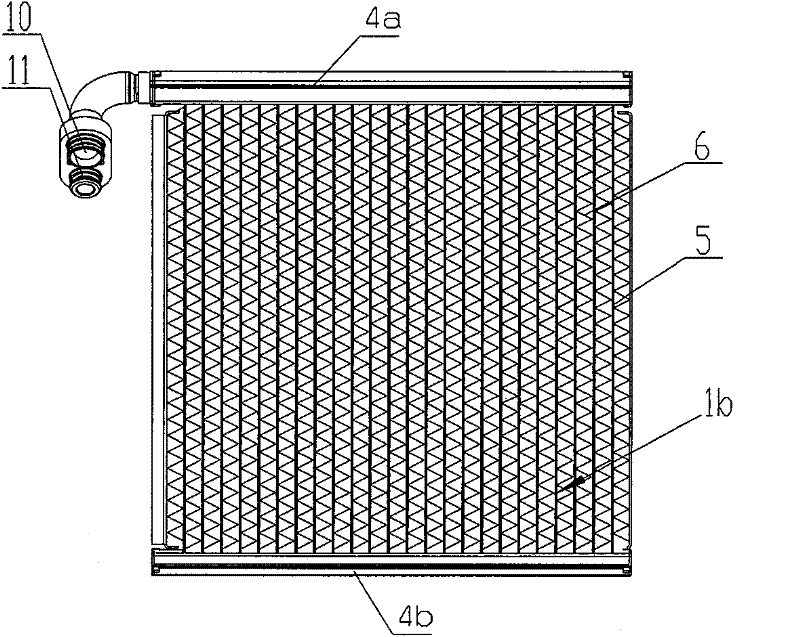

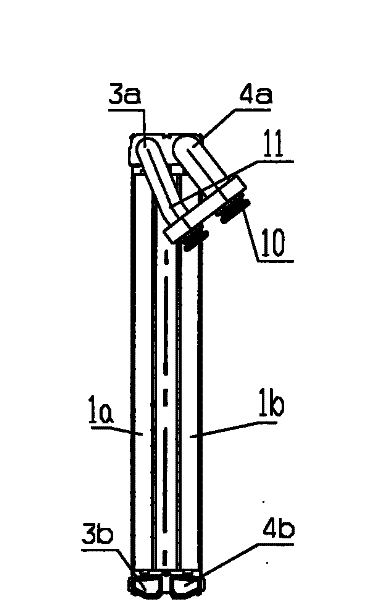

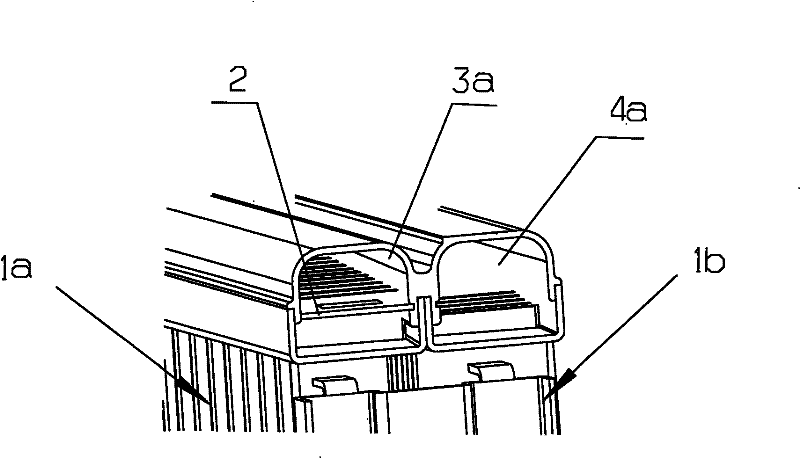

[0040] Embodiment 1: as figure 1 and figure 2 As shown, an evaporator includes: an inlet-side heat exchange tube group 1a and an outlet-side heat exchange tube group 1b composed of heat exchange tubes 5 arranged in parallel at a certain interval; and the inlet-side heat exchange tube group 1a and The outlet-side heat exchange tube group 1b is a vertical water chamber, the water chamber includes an inlet-side upper water chamber arranged at both ends of the inlet-side heat exchange tube group 1a and communicating with the inlet-side heat exchange tube group 1a Chamber 3a and inlet-side lower water chamber 3b, outlet-side upper water chamber 4a and outlet-side lower water chamber 4b arranged at both ends of the outlet-side heat exchange tube group 1b and communicated with the outlet-side heat exchange tube group 1b, the The inlet-side lower water chamber 3b and the outlet-side lower water chamber 4b communicate with each other; the inlet-side upper water chamber 3a communicate...

Embodiment 2

[0044] Embodiment 2: as figure 1 and figure 2 As shown, an evaporator includes: an inlet-side heat exchange tube group 1a and an outlet-side heat exchange tube group 1b composed of heat exchange tubes 5 arranged in parallel at a certain interval; and the inlet-side heat exchange tube group 1a and The outlet-side heat exchange tube group 1b is a vertical water chamber, the water chamber includes an inlet-side upper water chamber arranged at both ends of the inlet-side heat exchange tube group 1a and communicating with the inlet-side heat exchange tube group 1a Chamber 3a and inlet-side lower water chamber 3b, outlet-side upper water chamber 4a and outlet-side lower water chamber 4b arranged at both ends of the outlet-side heat exchange tube group 1b and communicated with the outlet-side heat exchange tube group 1b, the The inlet-side lower water chamber 3b and the outlet-side lower water chamber 4b communicate with each other; the inlet-side upper water chamber 3a communicate...

Embodiment 3

[0047] Embodiment 3: as Figure 17 As shown, the difference between this embodiment and Embodiment 1 is that the inlet-side lower water chamber 3b and the outlet-side lower water chamber 4b are also inserted and fixed with splitter plates 2b and 2c, and the splitter plates 2b and 2c divide the inlet-side lower water The chamber 3b and the outlet-side water chamber 4b are divided into upper and lower parts; the distribution plates 2b and 2c are provided with distribution holes 7b and 7c; the distribution plates 2b and 2c are also provided with installation holes, heat exchange tubes 5 Welded in the mounting hole, the ends of which protrude from the manifolds 2b and 2c, and the protruding height is preferably 1 mm to 5 mm; the specific shapes of the manifolds 2b and 2c can be as follows Figure 6 to Figure 9 shown. Other structures of this embodiment are the same as those of Embodiment 1.

[0048] When the evaporator of this embodiment is in operation, part of the liquid refri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com