Cooling system of a superconducting machine

A technology of superconducting motors and cooling systems, applied in the usage of superconductor elements, cooling/ventilation devices, electrical components, etc., can solve the problems of weak cooling cycle and no longer able to guarantee the cooling of windings, and achieve the effect of preventing bending loads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

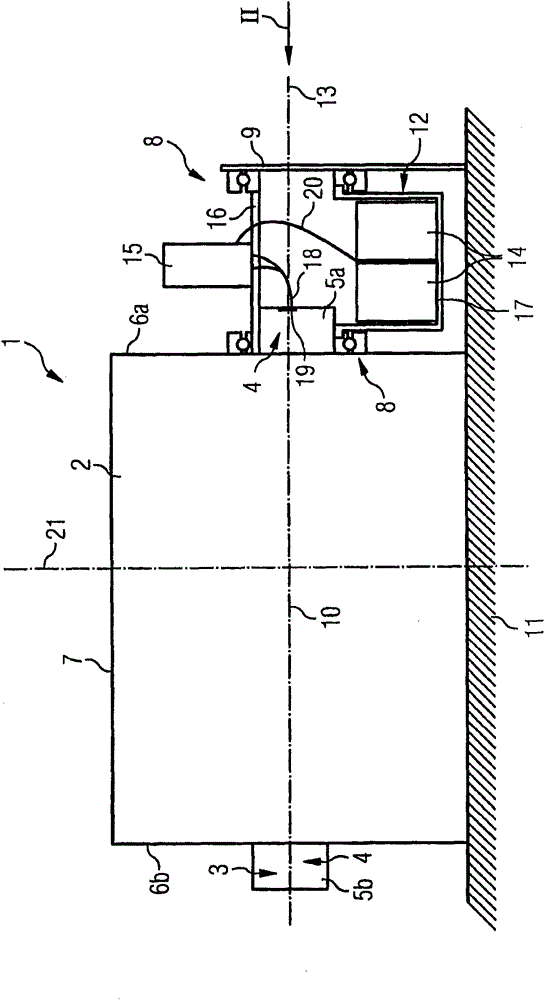

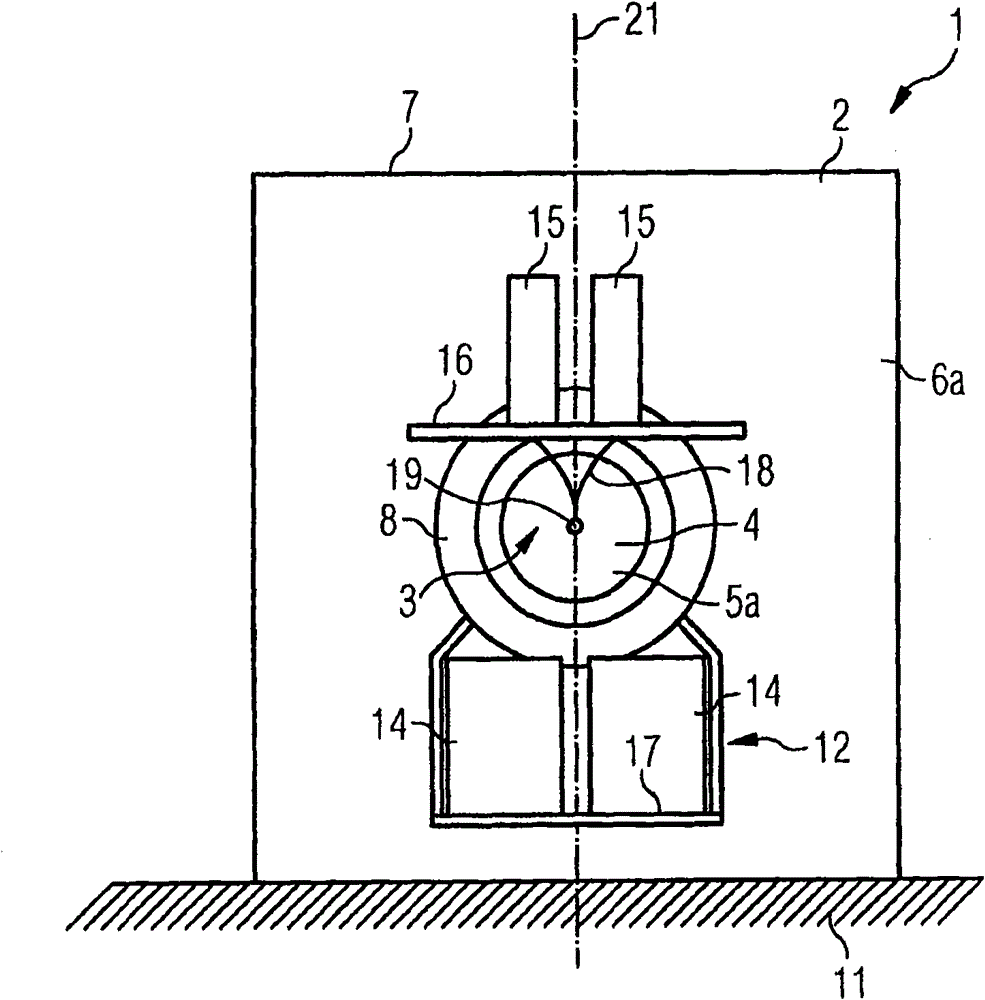

[0012] The electrical machine arrangement 1 shown in the figure has an electrical machine 2 and a cooling system. The electric machine is, for example, a synchronous electric motor or a generator, comprising a rotor 3 with a superconducting winding, in the figure only the rotor shaft 4 and its terminal section 5a protruding from the end walls 6a, 6b of the machine housing 7 , 5b is visible. The basic construction of electric machines with superconducting windings is known from the documents mentioned at the outset, to which reference is expressly made here. Arranged on the end wall 6 a is a circular link body 8 , wherein the link body is formed, for example, by a ball bearing or a roller bearing. A further link body 8 is fastened to a bracket 9 positioned at a distance from the end wall 6a, wherein this link body can likewise be designed as a rolling or ball bearing. The link body 8 is arranged coaxially to the axis of rotation 10 of the rotor 3 and serves to support a carri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com