Soft chemical method for synthesizing soft magnetic ferrite

A soft magnetic ferrite and soft chemical technology, applied in the direction of magnetic properties of inorganic materials, can solve problems such as uneven mixing of components, high sintering temperature, and difficulty in co-firing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

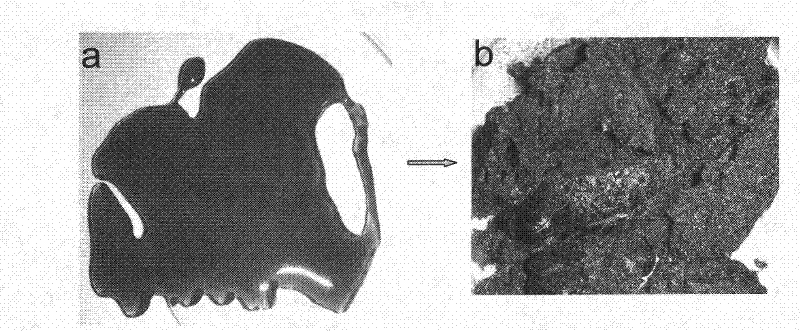

[0008] Specific embodiment one: the soft magnetic ferrite precursor that the soft chemical method of present embodiment is synthesized [will stir good metal element trivalent iron (Fe 3+ ), divalent metal elements M or N (M, N=Fe, Mn, Zn, Ni, Cu and other divalent metal elements) mixed with citric acid and obtained by rotary evaporation to remove water] from sol to gel state as shown in the figure 1.

[0009] The precursor of the soft ferrite in this embodiment is a sol, which is cured into a gel after heat treatment at 100 degrees. The gel is very brittle and turns into a solid powder with a little force.

specific Embodiment approach 2

[0010] Specific embodiment two: The soft magnetic ferrite synthesized by the soft chemical method of this embodiment has M x N 1-x Fe 2 o 4 (0≤x≤1, and M, N=Fe, Mn, Zn, Ni, Cu and other divalent metal elements) molecular formula of spinel or inverse spinel structure; element M or N can represent a single metal element, or Can represent two metal elements.

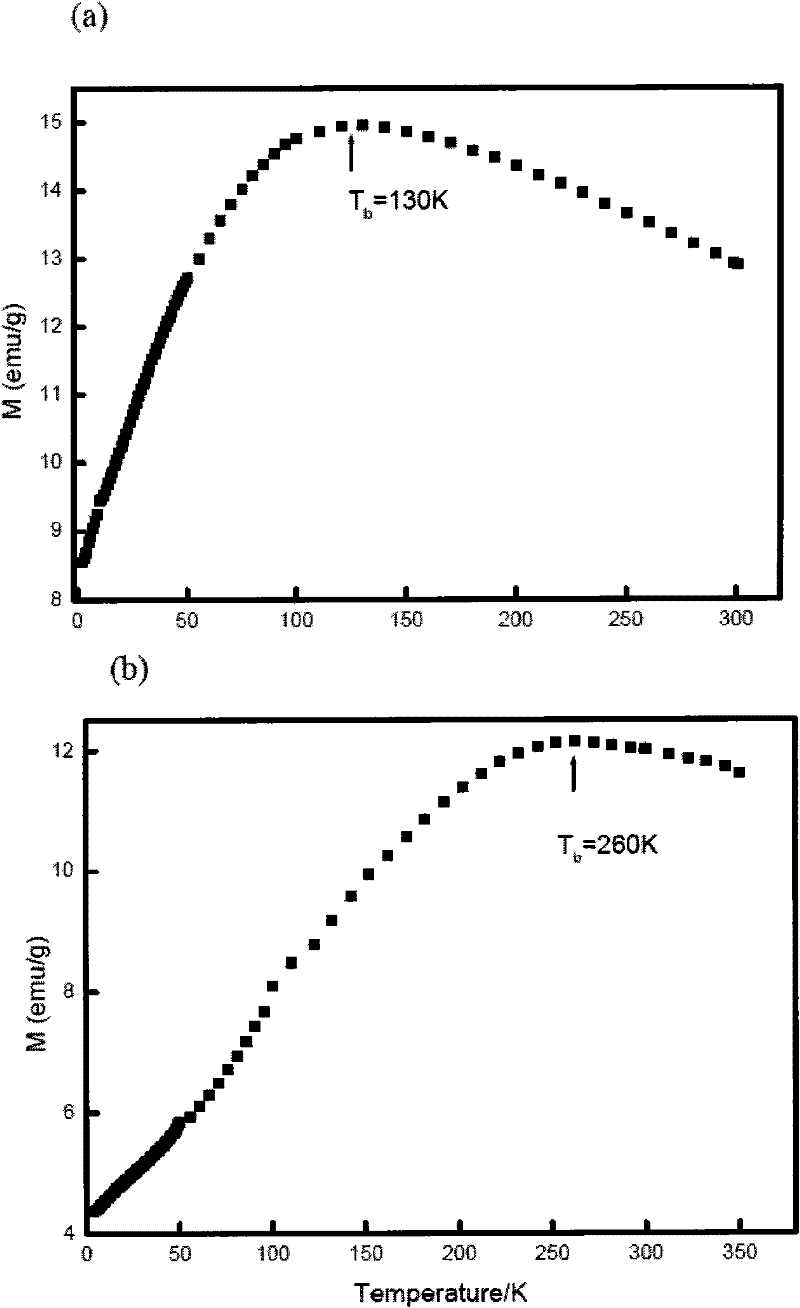

[0011] In this embodiment, the particle size of the soft ferrite in this embodiment is on the order of nanometers, and most of them have superparamagnetism at room temperature. In this embodiment, the divalent metal elements M or N are mixed in any proportion.

specific Embodiment approach 3

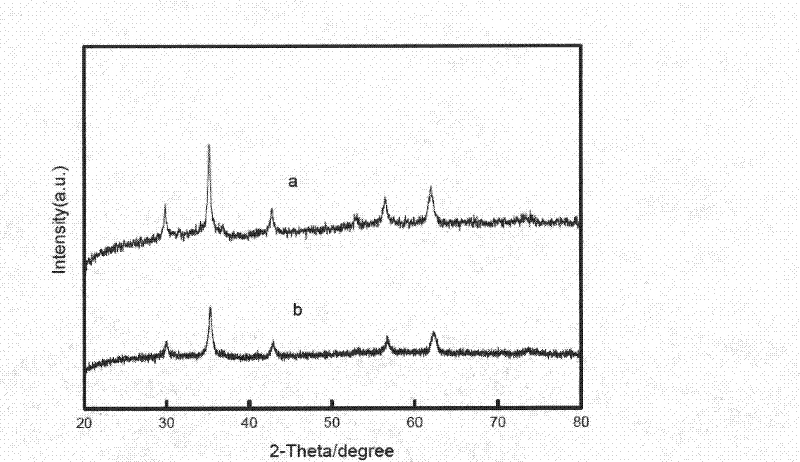

[0012] Specific embodiment three: the soft magnetic ferrite synthesized by the soft chemical method of the present embodiment has Mn x Cu 1-x Fe 2 o 4 (x = 1, 0.8) Molecular structure. The raw material iron nitrate [Fe(NO 3 ) 3 9H 2 O] Manufacturer: Beijing Chemical Reagent Factory; Manganese Nitrate [Mn(NO 3 ) 2 50% aqueous solution]: Shenyang Reagent Factory; citric acid [C 6 h 8 o 7 ·H 2 O]: Shenyang Xinxi Reagent Factory. The phase structure (XRD spectrum) is measured by German Siemens D5005 X-ray diffractometer, Cu target (λ=0.15418nm, tube pressure is 30kV, tube current 30mA) scan rate 1° / min, the size of soft ferrite is broadened by Calculated from the half width of the X-ray diffraction peak (Debye-Scherrer formula).

[0013] The MnFe prepared by this embodiment 2 o 4 and Mn 0.8 Cu 0.2 Fe 2 o 4 The powder X-ray diffraction spectrum (Fig. 2) of the sample, as can be seen from the figure, the position and intensity of the diffraction peaks are all the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com