Method for preparing high-performance ferrite material with microwave sintering method

A ferrite material and microwave sintering technology, which is applied in the field of preparing high-performance ferrite materials by microwave sintering, can solve the problems of deteriorating ferrite electromagnetic properties, easy abnormal growth of grains, easy segregation of material components, etc., and achieve Effects of inhibiting abnormal grain growth, increasing densification rate, improving sintering performance and electromagnetic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

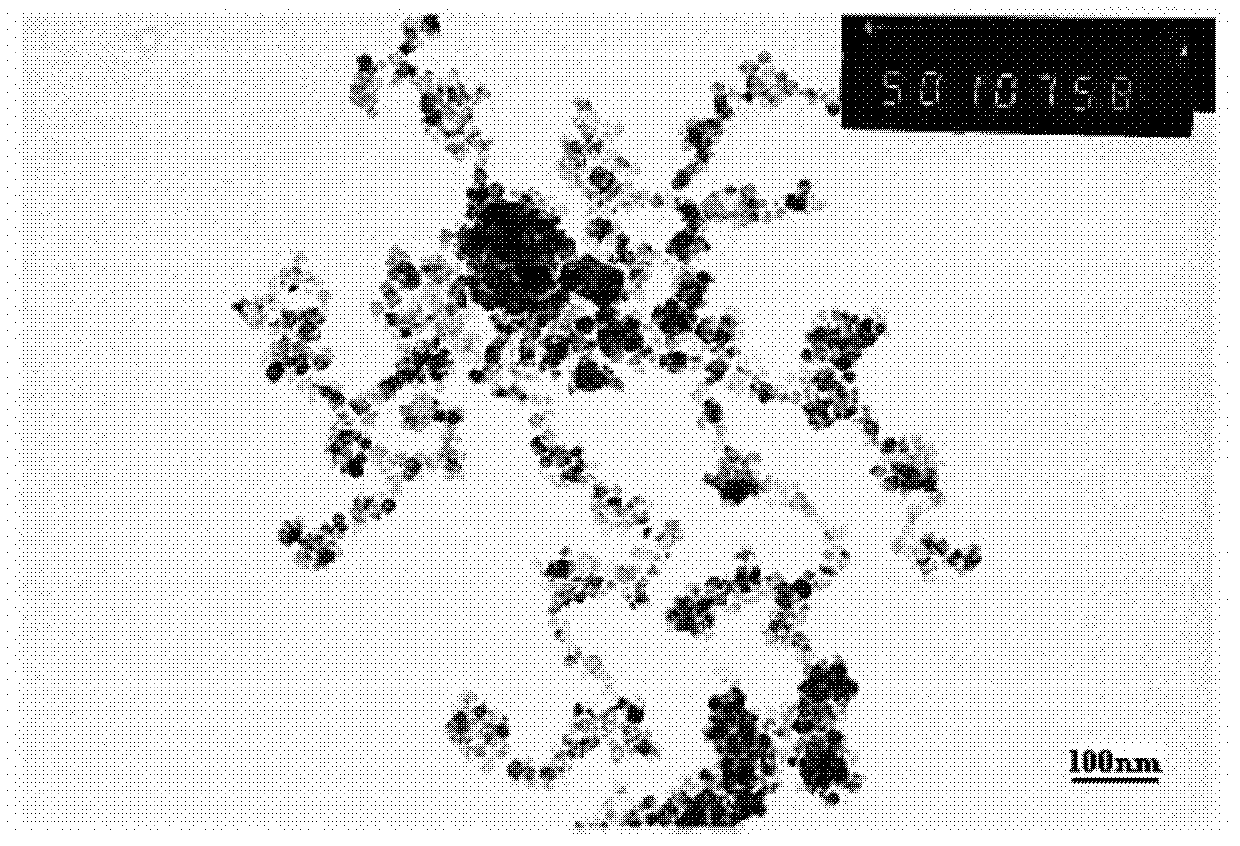

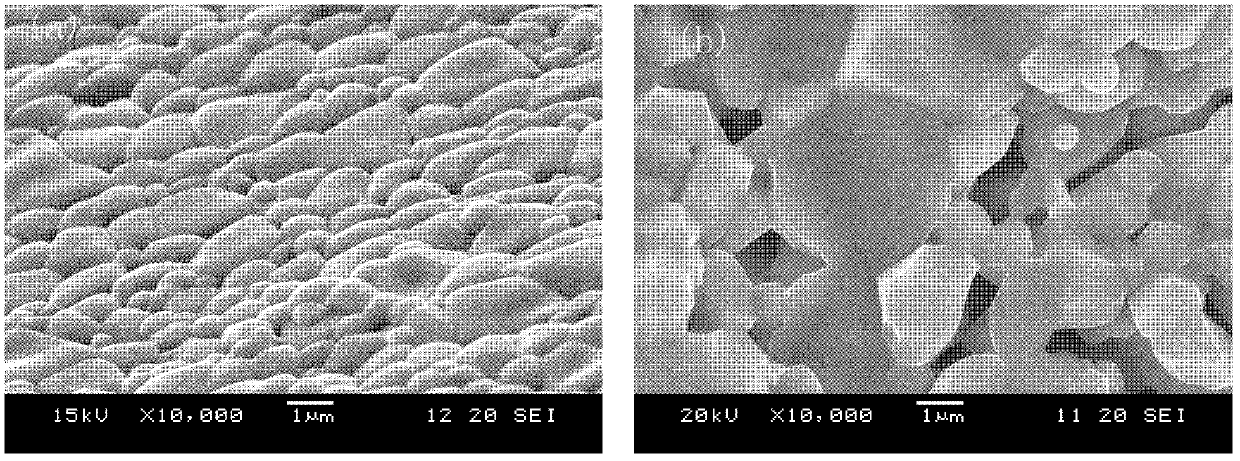

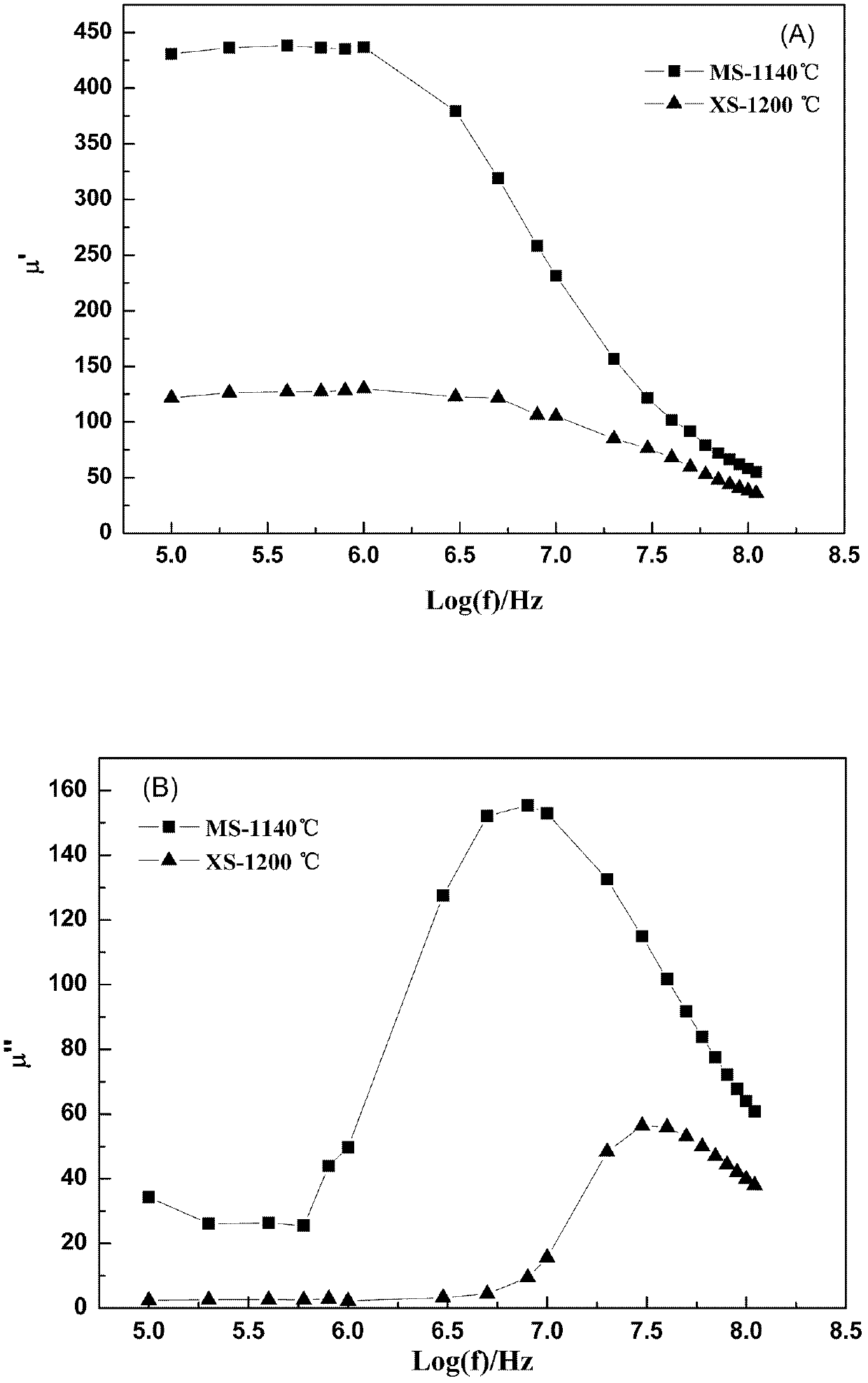

[0024] Take 9.8g nanometer Ni 0.4 Zn 0.6 Fe 2 o 4 Ferrite powder and 0.02g sintering aid CuO powder, put the raw materials into a polytetrafluoroethylene ball mill tank, use absolute ethanol as a grinding aid, ball mill for 6 hours, and then dry at 80°C for 24 hours to obtain a mixture. Nano-Ni used 0.4 Zn 0.6 Fe 2 o 4 The particle diameter of ferrite powder is 10-30nm, and particle is spherical shape, and size is uniform; Add the polyvinyl alcohol of 6% of mixture mass in the obtained mixture as binding agent and carry out granulation to obtain pellets, and the obtained pellets The material is passed through a 200-mesh sieve, and then pre-pressed at a pressure of 30 MPa at normal temperature to obtain a pre-pressed molding material, and then the pre-pressed molding material is cold-isostatically pressed at a molding pressure of 200 MPa at room temperature to obtain a molding material; the molding material is placed in a muffle In the furnace, heat up to 500°C at a heat...

Embodiment 2

[0027] This embodiment is a comparative test of embodiment 1.

[0028] Take 9.7g nanometer Ni 0.4 Zn 0.6 Fe 2 o 4 Ferrite powder and 0.03g of sintering aid CuO powder were put into a polytetrafluoroethylene ball mill jar, and absolute ethanol was used as a grinding aid, ball milled for 6 hours, and then dried at 80°C for 24 hours to obtain a mixture. Nano-Ni used 0.4 Zn 0.6 Fe 2 o 4 The particle size of the ferrite powder is 10-30nm, and the particles are spherical and uniform in size; then add polyvinyl alcohol with 5% of the mass of the mixture into the mixture as a binder, and granulate to obtain pellets. The material is passed through a 200-mesh sieve, and then pre-pressed at a pressure of 20 MPa at room temperature to obtain a pre-pressed molding material, and then the pre-pressed molding material is cold-isostatically pressed at room temperature with a molding pressure of 300 MPa to obtain a molding material; the molding material is placed in a high-temperature bo...

Embodiment 3

[0033] Take 9.0g nanometer Ni 0.5 Zn 0.5 Fe 2 o 4 Ferrite powder and 0.02g sintering aid CuO powder, put the raw materials into a polytetrafluoroethylene ball mill tank, use absolute ethanol as a grinding aid, ball mill for 6 hours, and then dry at 80°C for 24 hours to obtain a mixture. Nano-Ni used 0.5 Zn 0.5 Fe 2 o 4 The particle diameter of the ferrite powder is 10-30nm, and the particles are spherical and uniform in size; then add polyvinyl alcohol with 6% of the mass of the mixture as a binder to the mixture, and granulate to obtain pellets. The material is passed through a 200-mesh sieve, and then pre-pressed at a pressure of 30 MPa at room temperature to obtain a pre-pressed molding material, and then the pre-pressed molding material is cold-isostatically pressed at a molding pressure of 250 MPa at room temperature to obtain a molding material; the molding material is placed in a muffle In the furnace, heat up to 600°C at a heating rate of 3°C / min, then keep it w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com