Preparation method of ultra-thin and dense electrolyte for solid oxide battery and ultra-thin and dense electrolyte obtained therefrom

A technology of solid oxides and electrolytes, applied in the direction of electrolyte immobilization/gelation, fuel cells, circuits, etc., can solve the problems of easy damage to functional layers, easy opening of holes and air leakage, etc., to save energy costs and sintering temperature The effect of reducing and improving the electrochemical performance of SOC

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] 25g YSZ powder (accounting for 30% of the slurry mass), 1g MIL-88 (Fe-MOF), 2g triethanolamine, 3g ethyl cellulose, 2.5g dioctyl phthalate and 50g terpineol were mixed to obtain Mixed electrolyte slurry.

[0031] After the mixed electrolyte slurry is ball-milled, it is further ground on a three-roll machine to obtain a ground electrolyte slurry.

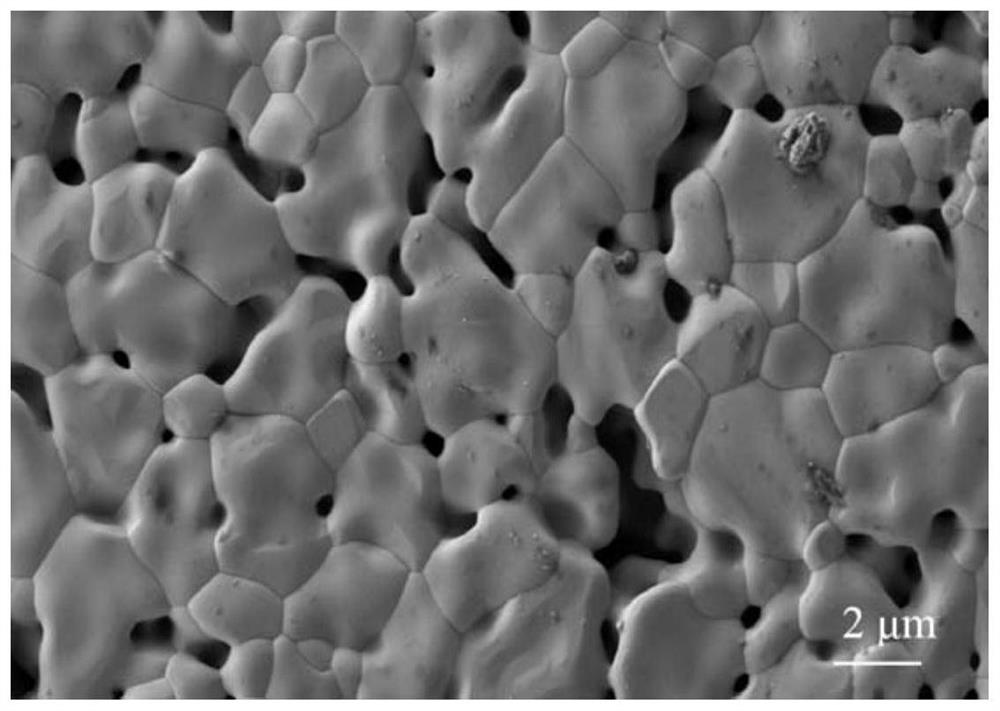

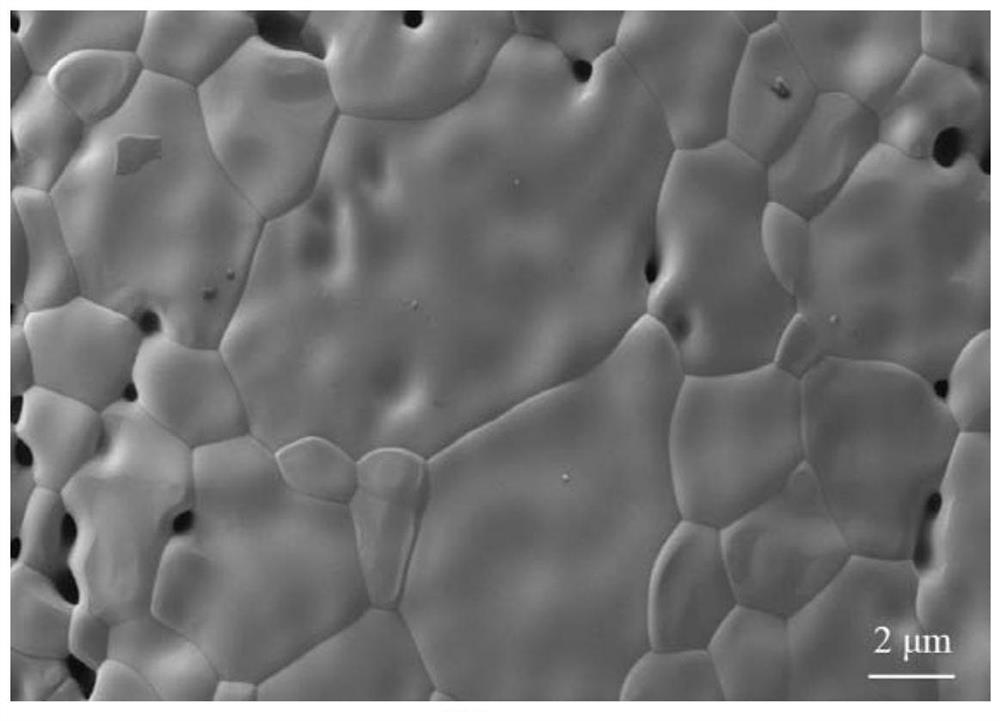

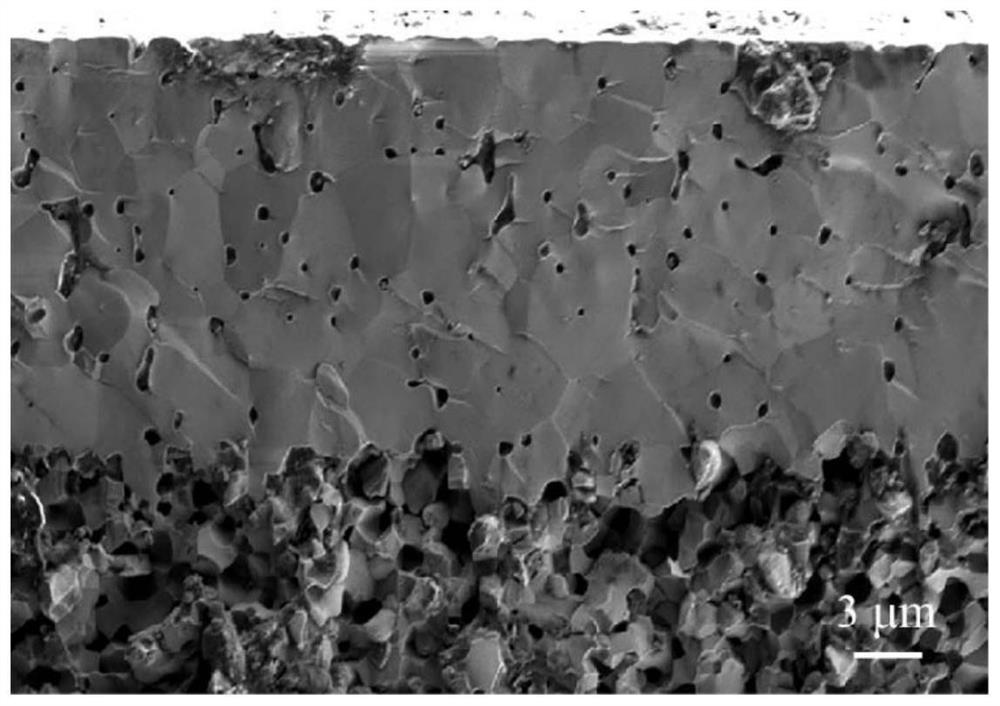

[0032] Using the screen printing method, the ground electrolyte slurry was evenly printed on the half-cell green embryo (the hydrogen electrode was NiO-3YSZ, and the functional layer was NiO-8YSZ). electrolyte. The scanning electron microscope photograph of the surface of the dense electrolyte is shown in Figure 1B shown, with Figure 1A Compared with the SEM photo of the electrolyte surface obtained without MOFs addition, the electrolyte obtained by adding MOFs according to the present invention is more dense. The scanning electron microscope photograph of the electrolyte cross-section of the surface of the dense electrol...

Embodiment 2

[0035] 108g cerium oxide powder (accounting for 65% of the slurry), 1Gzif-67 (Co-MOF), 2g triethanolamine, 3g ethyl cellulose, 2.5g dioctyl phthalate and 50g terpineol were mixed to obtain Mixed electrolyte slurry.

[0036] After the mixed electrolyte slurry is ball-milled, it is further ground on a three-roll machine to obtain a ground electrolyte slurry.

[0037] Using the screen printing method, the ground electrolyte slurry was evenly printed on the half-cell green embryo (the hydrogen electrode was NiO-3YSZ, and the functional layer was NiO-8YSZ). electrolyte.

[0038] Electrochemical testing of cells with dense electrolytes such as image 3 and Figure 4 It can be seen that the open-circuit voltage, power and charging current in the charging mode are higher than those of the battery assembled without MOFs electrolyte, and the electrochemical performance is good.

Embodiment 3

[0040] Mix 25g barium oxide powder (30% of the slurry), 1g CTGU (Ni-MOF), 2g triethanolamine, 3g ethyl cellulose, 2.5g dioctyl phthalate and 50g terpineol to obtain a mixed electrolyte slurry.

[0041] After the mixed electrolyte slurry is ball-milled, it is further ground on a three-roll machine to obtain a ground electrolyte slurry.

[0042] Using the screen printing method, the ground electrolyte slurry was evenly printed on the half-cell green embryo (the hydrogen electrode was NiO-3YSZ, and the functional layer was NiO-8YSZ). electrolyte.

[0043] Electrochemical testing of cells with dense electrolytes such as image 3 and Figure 4 As shown, it can be seen that the open-circuit voltage, power and charging current in the discharging mode are higher than those of the battery assembled without MOFs electrolyte, and the electrochemical performance is good.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com