A kind of preparation method of surface protective layer of chip type ceramic PTC thermistor

A thermistor and protective layer technology, which is applied in the field of preparation of the surface protective layer of chip ceramic PTC thermistors, can solve the problems of poor corrosion resistance of electroplating solution and poor matching.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The present embodiment provides a kind of concrete process of preparing chip type ceramic PTC thermistor surface protection layer according to above-mentioned method:

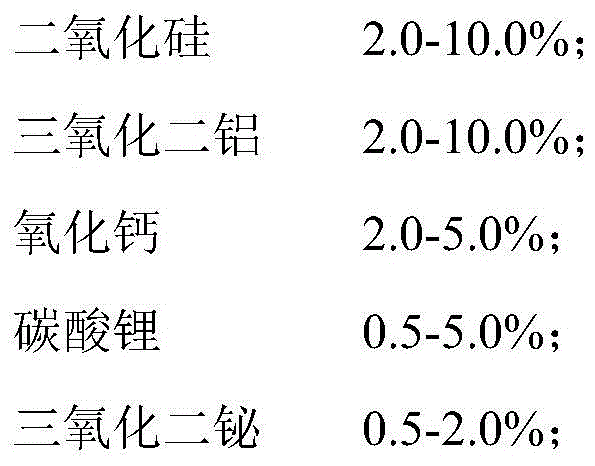

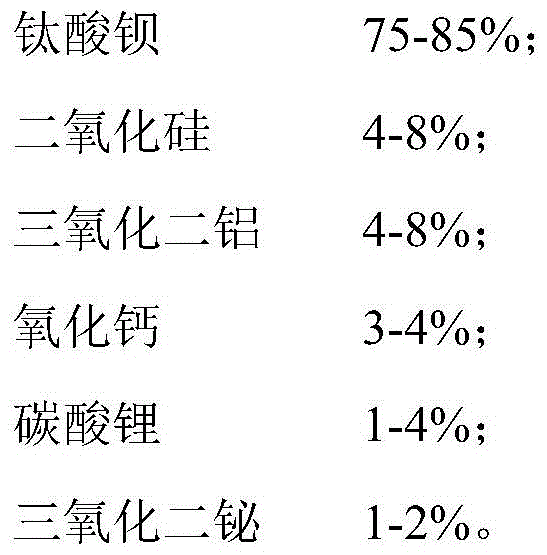

[0027] 1) According to the number of parts by mass: take 100 parts of inorganic powder; 90 parts of organic solvent, wherein 90 parts of organic solvent includes 10 parts of ethanol, 60 parts of isobutanol, 20 parts of terpineol; and trioleic acid as a dispersant 0.8 part of glyceride. 100 parts of the inorganic powder include 82.5 parts of barium titanate, 5.5 parts of silicon dioxide, 5 parts of aluminum oxide, 3 parts of calcium oxide, 2.5 parts of lithium carbonate, and 1.5 parts of bismuth trioxide. The inorganic powder, the organic solvent and the dispersant are mixed and ball-milled for about 6 hours to obtain the precursor of the slurry used for preparing the protective layer of the sheet-type ceramic PTC thermistor.

[0028] 2) Add 8 parts of polymethyl methacrylate as a binder to the precursor...

Embodiment 2

[0032] 1) According to the number of parts by mass: take 100 parts of inorganic powder; 60 parts of organic solvent, wherein 60 parts of organic solvent includes 5 parts of ethanol, 45 parts of isopropanol, 10 parts of ethylene glycol; and 0.6 parts of oleic acid as a dispersant share. 100 parts of the inorganic powder include 75 parts of barium titanate, 8 parts of silicon dioxide, 8 parts of aluminum oxide, 4 parts of calcium oxide, 4 parts of lithium carbonate, and 1 part of bismuth trioxide. The inorganic powder, the organic solvent and the dispersant are mixed and ball-milled for about 5 hours to obtain the precursor of the slurry used for preparing the protective layer of the chip ceramic PTC thermistor.

[0033] 2) Add 6 parts of ethyl cellulose as a binder to the precursor obtained in the above 1), mix and ball mill again for about 8.5 hours to obtain a slurry for preparing a protective layer of a chip ceramic PTC thermistor.

Embodiment 3

[0037] 1) According to the number of parts by mass: take 100 parts of inorganic powder, 80 parts of organic solvent, wherein 80 parts of organic solvent includes 8 parts of ethyl acetate, 60 g of isobutanol, 12 g of n-propanol; and 0.8 part of fish oil as a dispersant . 100 parts of the inorganic powder include 85 parts of barium titanate, 4 parts of silicon dioxide, 4 parts of aluminum oxide, 3 parts of calcium oxide, 3 parts of lithium carbonate, and 1 part of bismuth trioxide. The inorganic powder, the organic solvent and the dispersant were mixed and ball-milled for 6.5 hours to obtain a slurry precursor for preparing a protective layer of a chip ceramic PTC thermistor.

[0038] 2) Add 8 parts of polyvinyl butyral as a binder to the precursor prepared in the above 1), and mix and ball mill again for 8 hours to obtain a slurry for preparing a protective layer of a chip ceramic PTC thermistor.

[0039] 3) Use a coating machine to evenly coat the protective layer slurry prep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com