Production of resistant starch product

A starch and product technology, applied in the field of resistant starch product production, can solve problems such as high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Preparation of heat / moisture treated resistant starch:

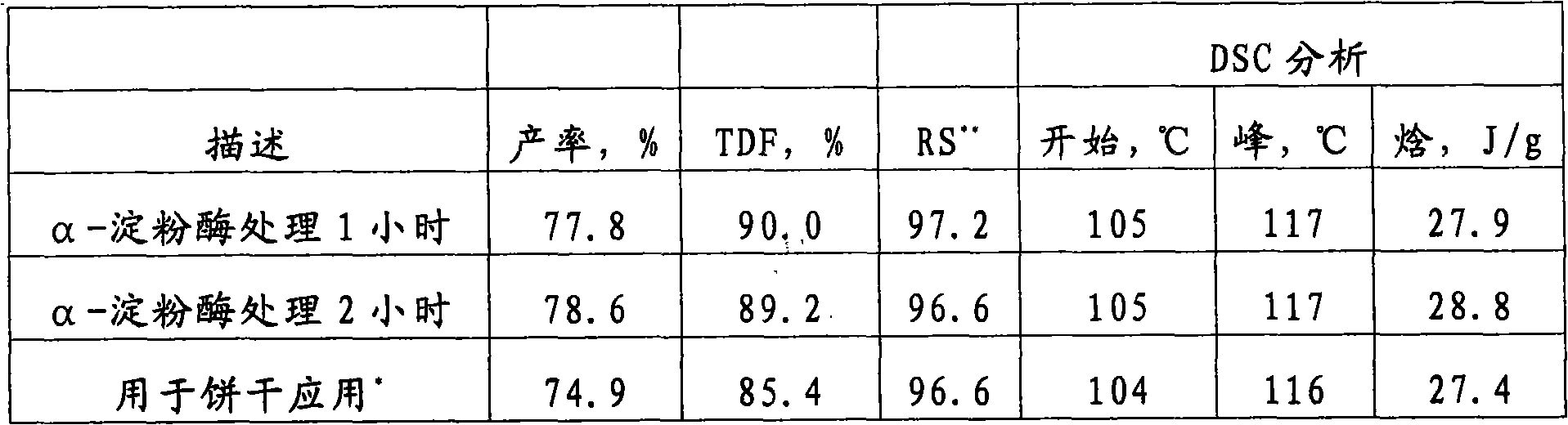

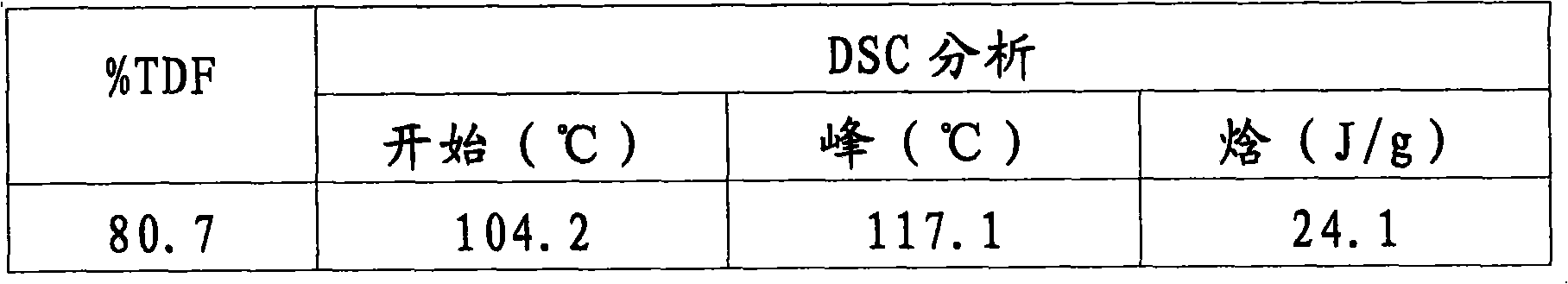

[0042] 250 lb regular dent corn starch and 1420 lb water were added to the vessel to create a 15% starch slurry. The starch slurry was jet cooked at approximately 149°C at a feed rate of approximately 2.0 gpm, and the resulting paste was quickly transferred to a tank maintained at approximately 88°C with agitation. As the dent cornstarch paste enters the tank, a total of approximately 8,000 GTU / lb starch of 4-alpha-glucanotransferase (obtained from Novozymes ). The mixture was reacted at 88° C. for 3 hours with stirring. Dilute sulfuric acid was added to adjust the pH to 3.8-3.9 and the reactor contents were rapidly cooled to approximately 55°C by pumping through a heat exchanger into a stirred tank maintained at 55°C. 0.1 ml / 100 g of starch of isoamylase obtained from Hayashibara Co. was added to the slurry, and the enzyme was reacted at 55°C for 16 hours while maintaining pH 3.8-3.9. The slurry was then jet ...

Embodiment 2

[0050] Preparation of resistant starch:

[0051]250 lbs of regular dent corn starch were added to sufficient water to obtain a 17.5% starch slurry. The starch slurry was jet cooked at approximately 149°C at a feed rate of approximately 2.0 gpm, and the resulting paste was quickly transferred to a tank maintained at approximately 88°C with agitation. 4-alpha-glucanotransferase (obtained from Novozymes) was added to the dent cornstarch paste as it entered the tank. A total of approximately 8,000 GTU / lb was added over the time the mash was pumped into the tank. The mixture was reacted at 88° C. for 3 hours with stirring. Dilute sulfuric acid was added to adjust the pH to 3.8-3.9 and the reactor contents were rapidly cooled to approximately 55°C by pumping through a heat exchanger into a stirred tank maintained at 55°C. 0.1 ml / 100 g of starch of isoamylase obtained from Hayashibara Co. was added to the slurry, and the enzyme was reacted at 55°C for 16 hours while maintaining pH...

Embodiment 3

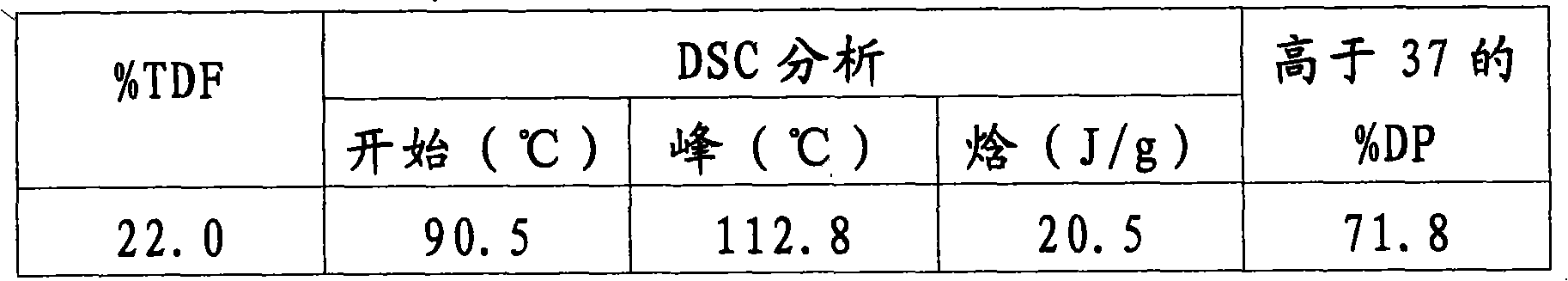

[0057] Preparation of material with mostly "A" crystals

[0058] 250 lbs of regular dent corn starch was added to sufficient water to produce a 17.5% starch slurry. The starch slurry was jet cooked at approximately 150°C at a feed rate of approximately 2 gpm, and the resulting paste was quickly transferred to a tank maintained at approximately 88°C with agitation. 2400 GTU / lb of starch 4-alpha-glucanotransferase (obtained from Novozymes) was added to the dent cornstarch paste throughout the time the paste was pumped into the tank. The mixture was reacted at 88° C. for 3 hours with stirring. Dilute sulfuric acid was added to adjust the pH to 3.8-3.9 and the reactor contents were rapidly cooled to approximately 55°C by pumping through a heat exchanger into a stirred tank maintained at 55°C. 0.1 ml / 100 g of starch of isoamylase obtained from Hayashibara Co. was added to the slurry, and the enzyme was reacted at 55°C for 16 hours while maintaining pH 3.8-3.9. The slurry was the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com