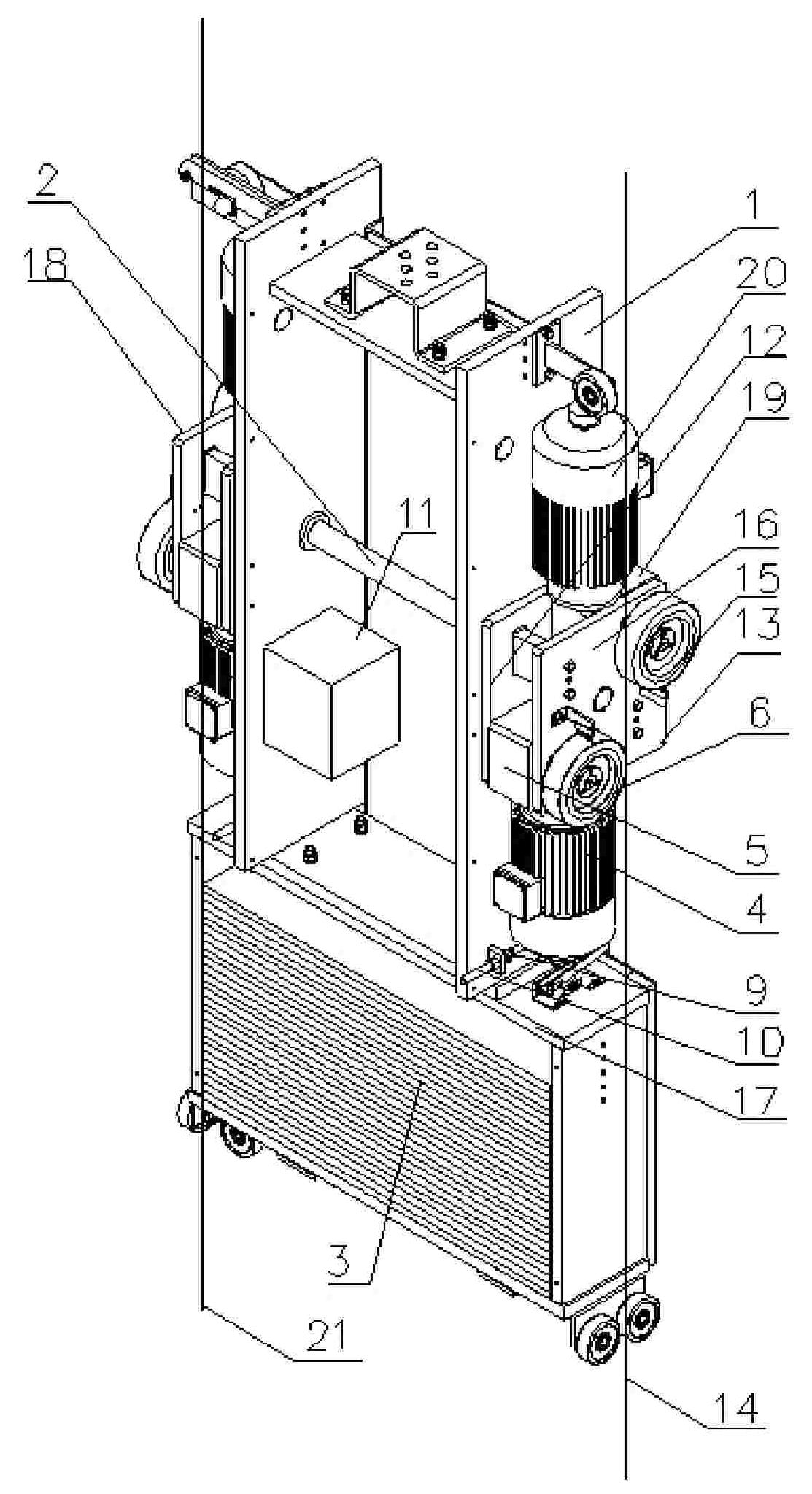

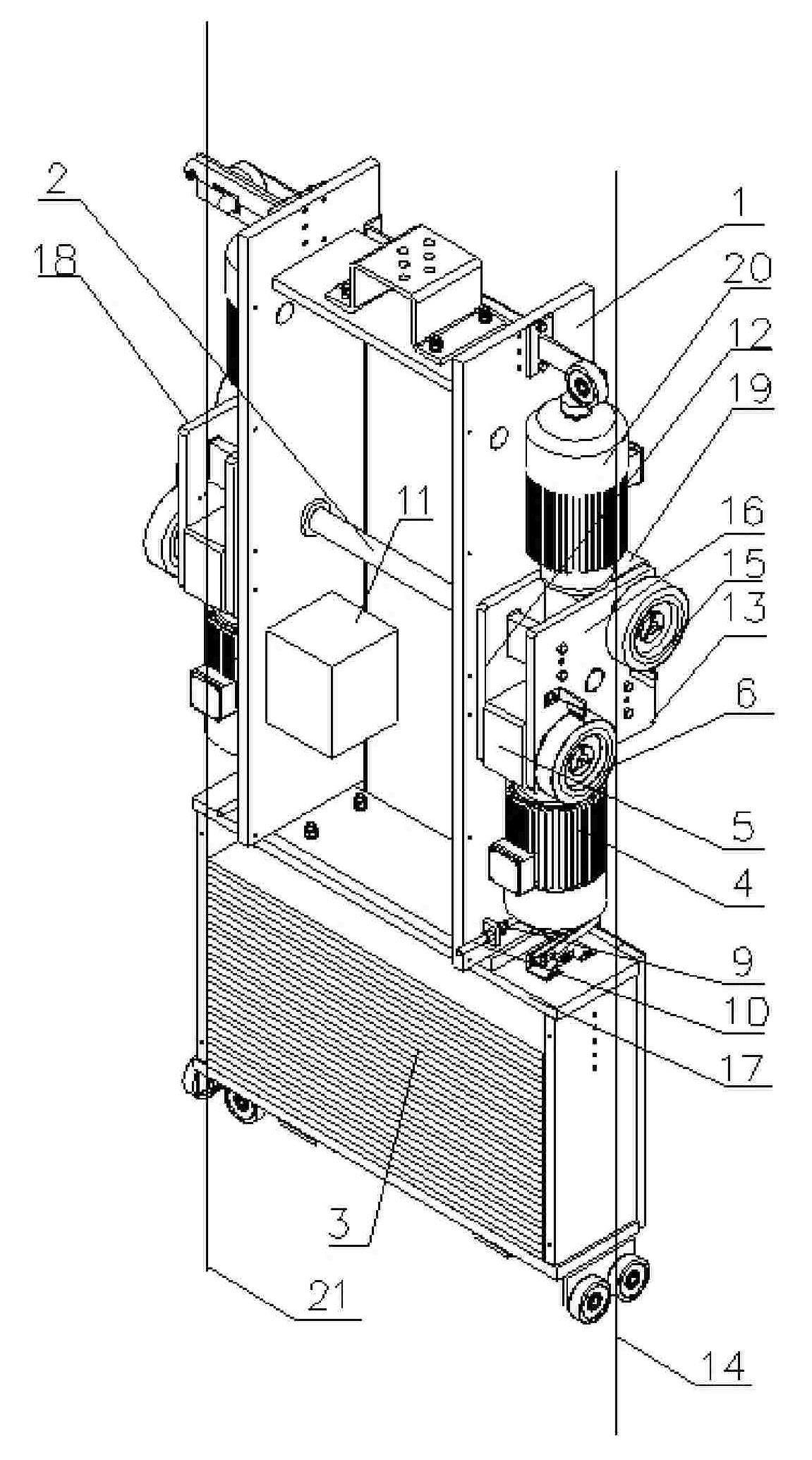

Machine-room-less elevator counterweight traction device

A technology of machine room-less elevator and driving device, which is applied to elevators, transportation and packaging in buildings, etc., to achieve the effect of facilitating installation and maintenance and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with the accompanying drawings.

[0010] Referring to the drawings, this embodiment includes a main frame 1, the bottom of the main frame 1 is fixed with a counterweight frame 17 by bolts, the counterweight frame 17 is provided with a counterweight iron 3, and the main frame 1 is provided with electrical components and safety devices. The installation cabinet 11, the main frame 1 is also provided with a shaft 2; the right side of the main frame 1 is provided with a driving device I16, and the driving device I16 includes a motor I 4, a motor II 20, a reducer I 5, a reducer II 19, and a gas spring 9. Movable ejector rod 10, rotating arm plate III12, rotating arm plate IV13, roller I 6, roller II 15, the right end of shaft 2 is connected with rotating arm plate III12 and rotating arm plate IV13 through bearings, reducer II 19, reducer I 5. It is installed symmetrically up and down between the rotating arm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com