Probe card

A technology of probe cards and substrates, applied in the field of probe cards, can solve problems such as inability to further improve, plate burst, drill bit breakage of drilling holes, etc., achieve decentralized production risks, reduce production costs, and facilitate mass production of modularization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

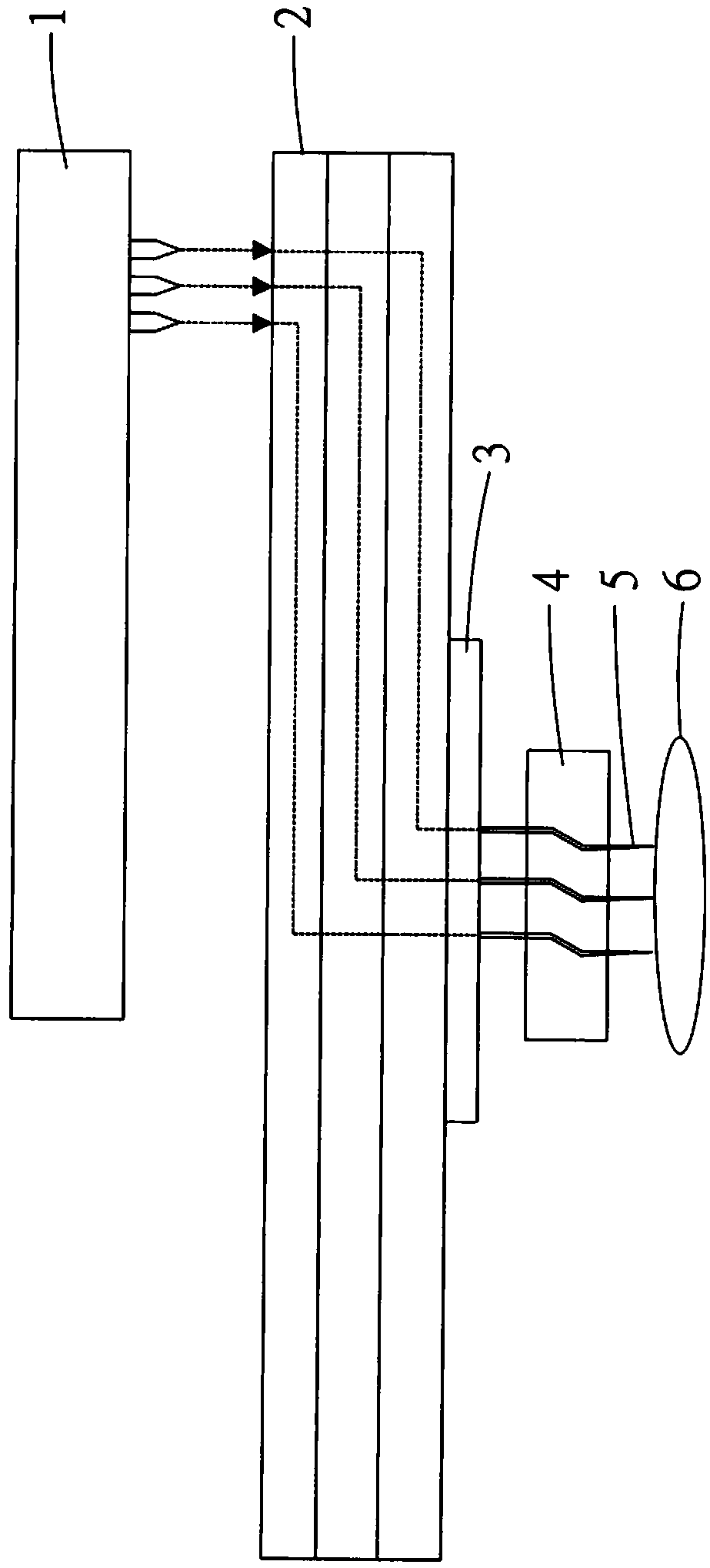

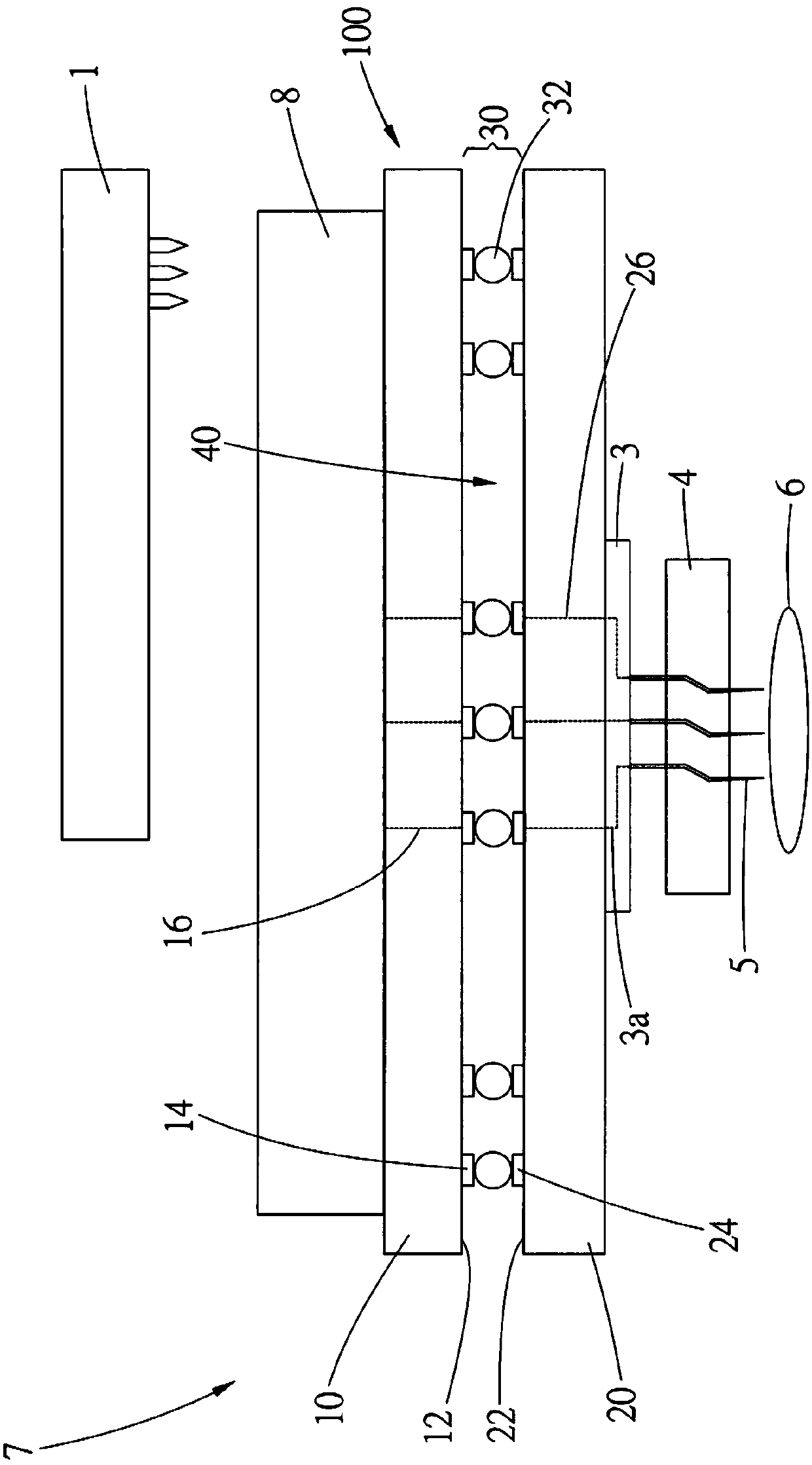

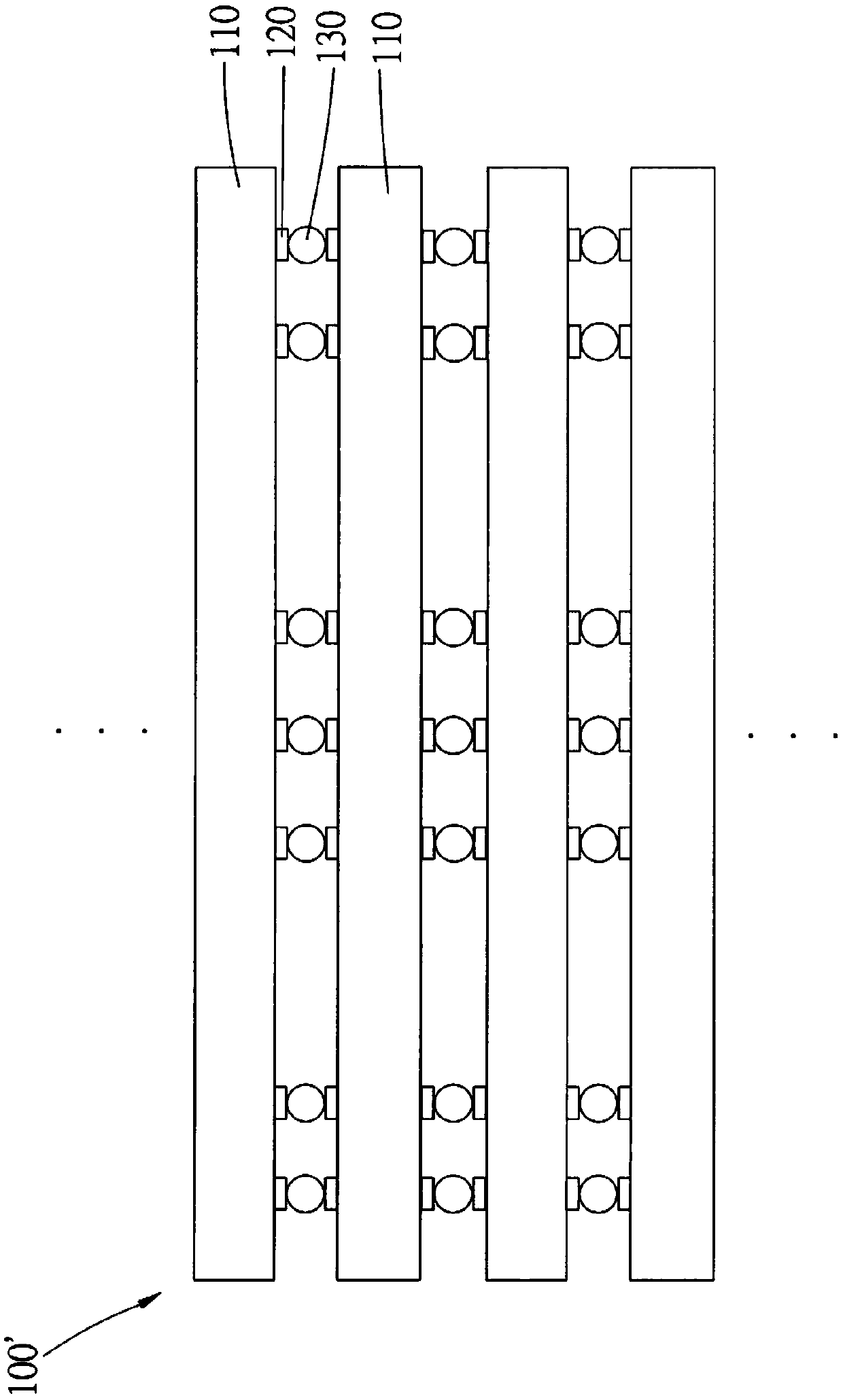

[0059] In order to illustrate the present invention more clearly, embodiments are given and detailed descriptions are as follows in conjunction with the accompanying drawings. Please refer to figure 2Shown is a probe card 7 according to a first embodiment of the present invention, which is used to transmit a signal of a tester 1 to an electronic object 6 to be tested, and includes a modular circuit board 100 and a plurality of probes 5 . The modular circuit board 100 includes a first substrate 10 , a second substrate 20 and an interposer 30 .

[0060] The first substrate 10 has a first surface 12 on which a plurality of first conductive pads 14 are arranged, and in addition, a plurality of first conductive circuits 16 are arranged in the first substrate 10 (Fig. Only some lines are shown in the formula), one end of these first conductive lines 16 is connected to the transmission interface (not shown) on the upper surface (the surface opposite to the first surface 12), and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com