Device and method for controlling cold-rolling steel strip pickling turbulence

A turbulent flow, strip technology, applied in the direction of electrical program control, etc., can solve the problems of strip steel over-pickling, turbulent flow control has not yet been seen, and achieve the effect of reducing equipment damage, simple structure, and avoiding over-pickling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

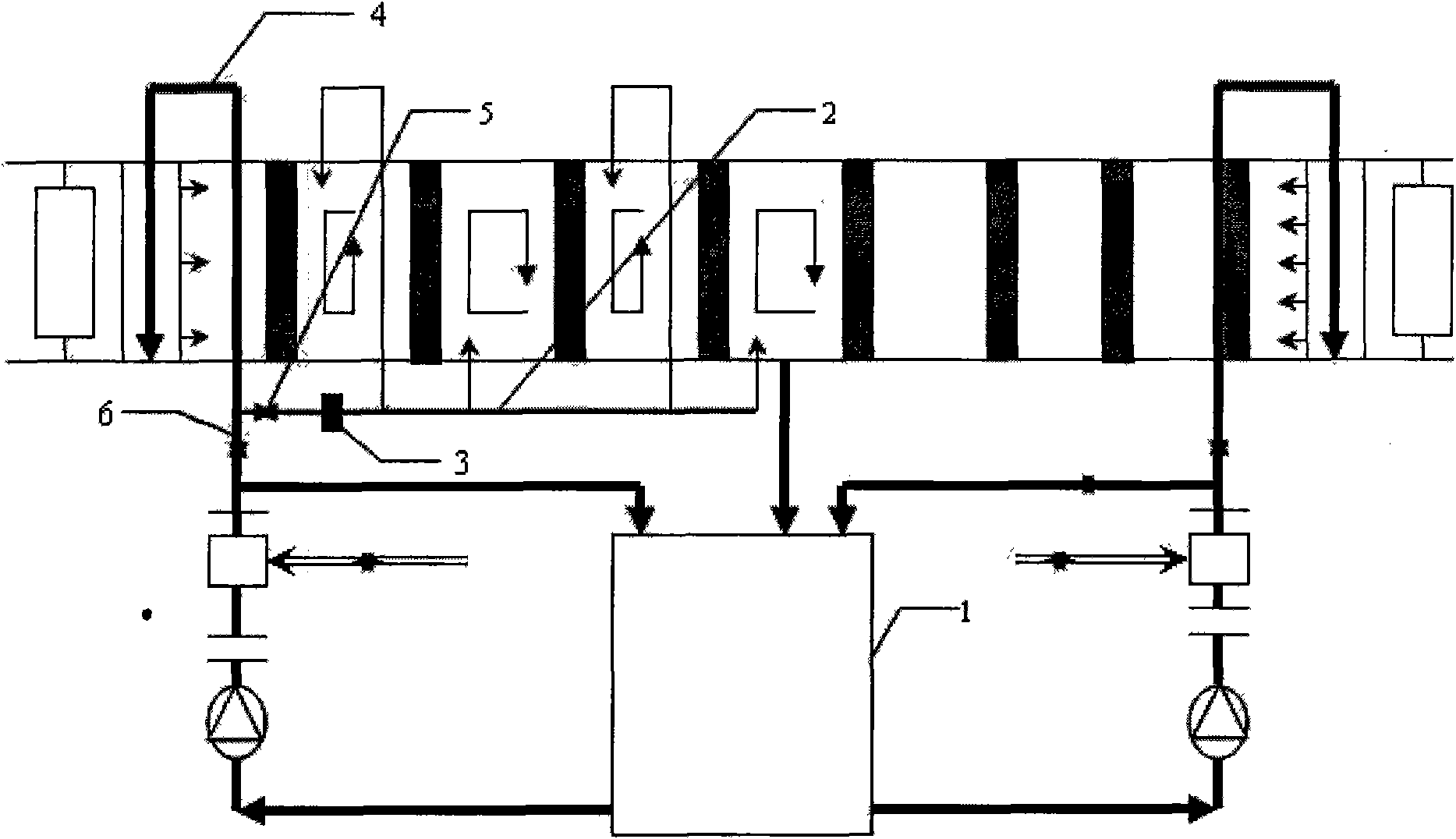

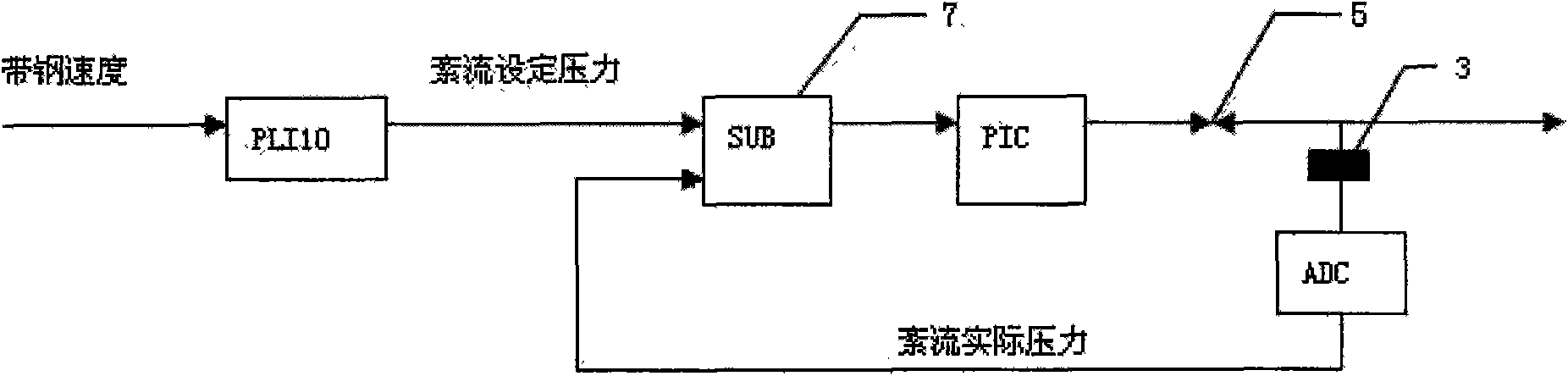

[0022] Depend on figure 1 It can be seen that the cold-rolled strip pickling turbulence control device of the present invention is mainly composed of a side acid spray valve 5, a pressure gauge 3, a side acid spray pipeline 2, a main acid spray pipeline 4 and an external computer. The main acid spraying pipeline 4 is connected with the pickling circulation tank 1 via the main acid spraying valve 6, heater, flow meter and acid pump, and the acid solution is supplied and stored by the pickling circulation tank 1 . The side acid spray valve 5 is connected to the main acid spray pipe 4 at the rear of the main acid spray valve 6; A branch acid spray pipe is also connected to spray acid solution to the strip. The side injection acid valve 5 and the pressure gauge 3 are also respectively connected with the external computer. The external computer is equipped with PLI10 curve function block, ADC analog-to-digital conversion function block, PIC proportional integral adjustment functi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com