Pinch roll type forced centering device

A technology of forced centering and pinch rollers, applied in transportation and packaging, coiling strips, thin material handling, etc., can solve problems affecting the quality of steel strips, improve product quality and yield, improve continuity, Avoid over-pickling effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

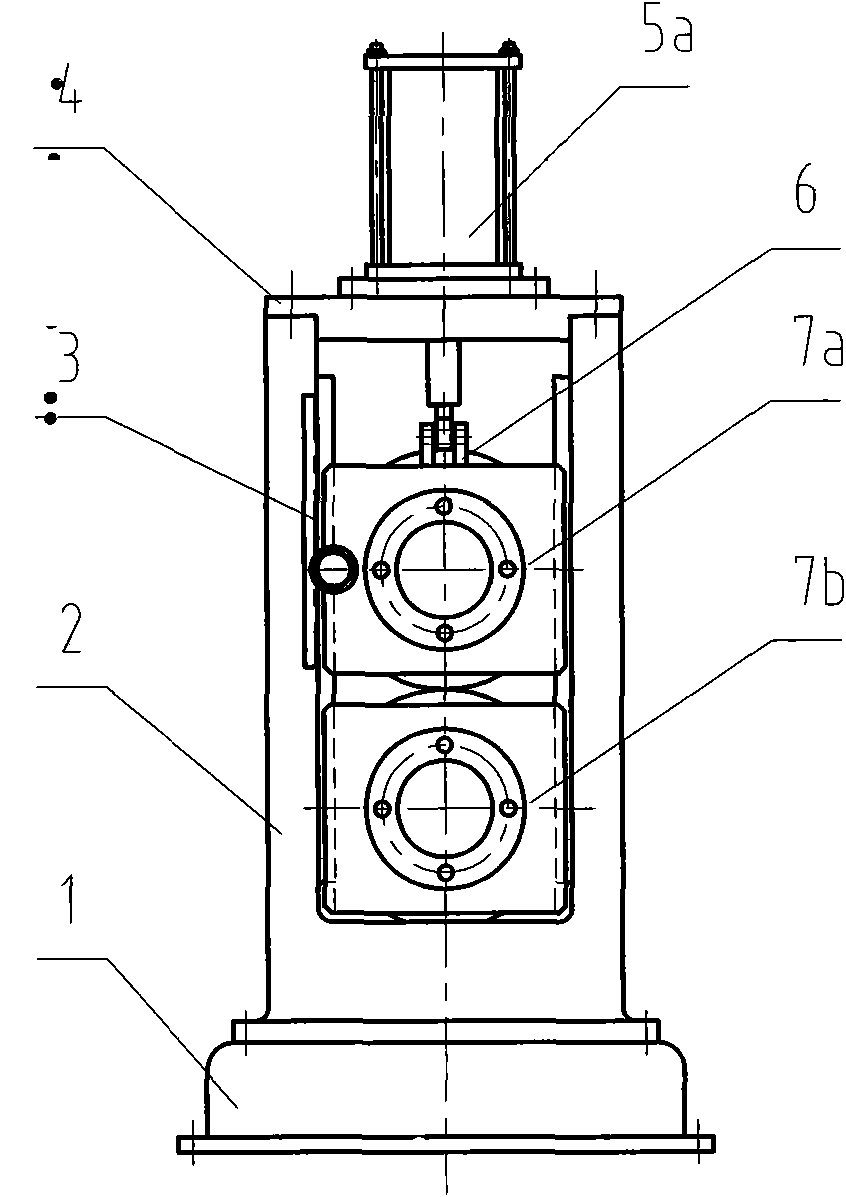

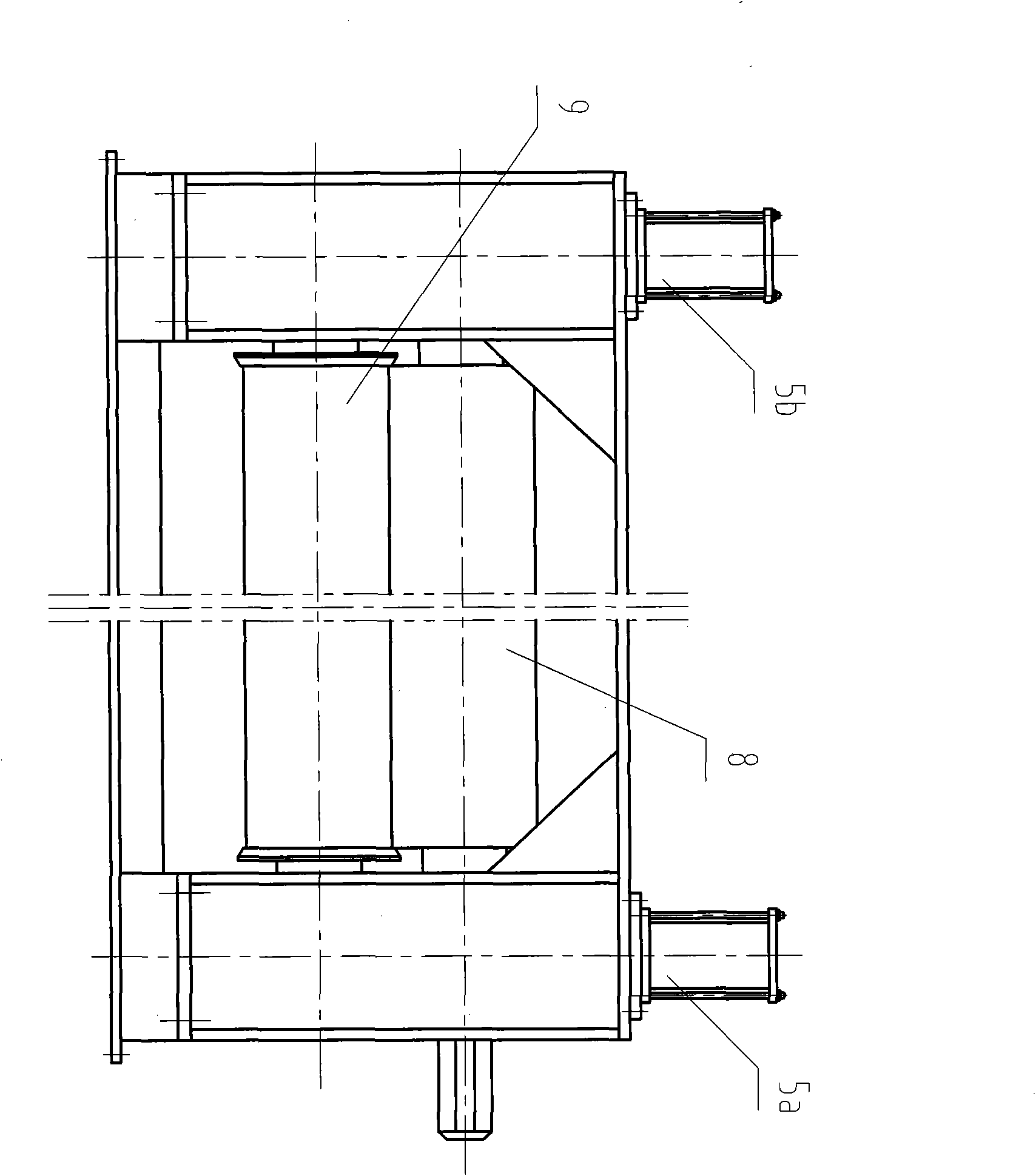

[0035] A preferred embodiment of the present invention is given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

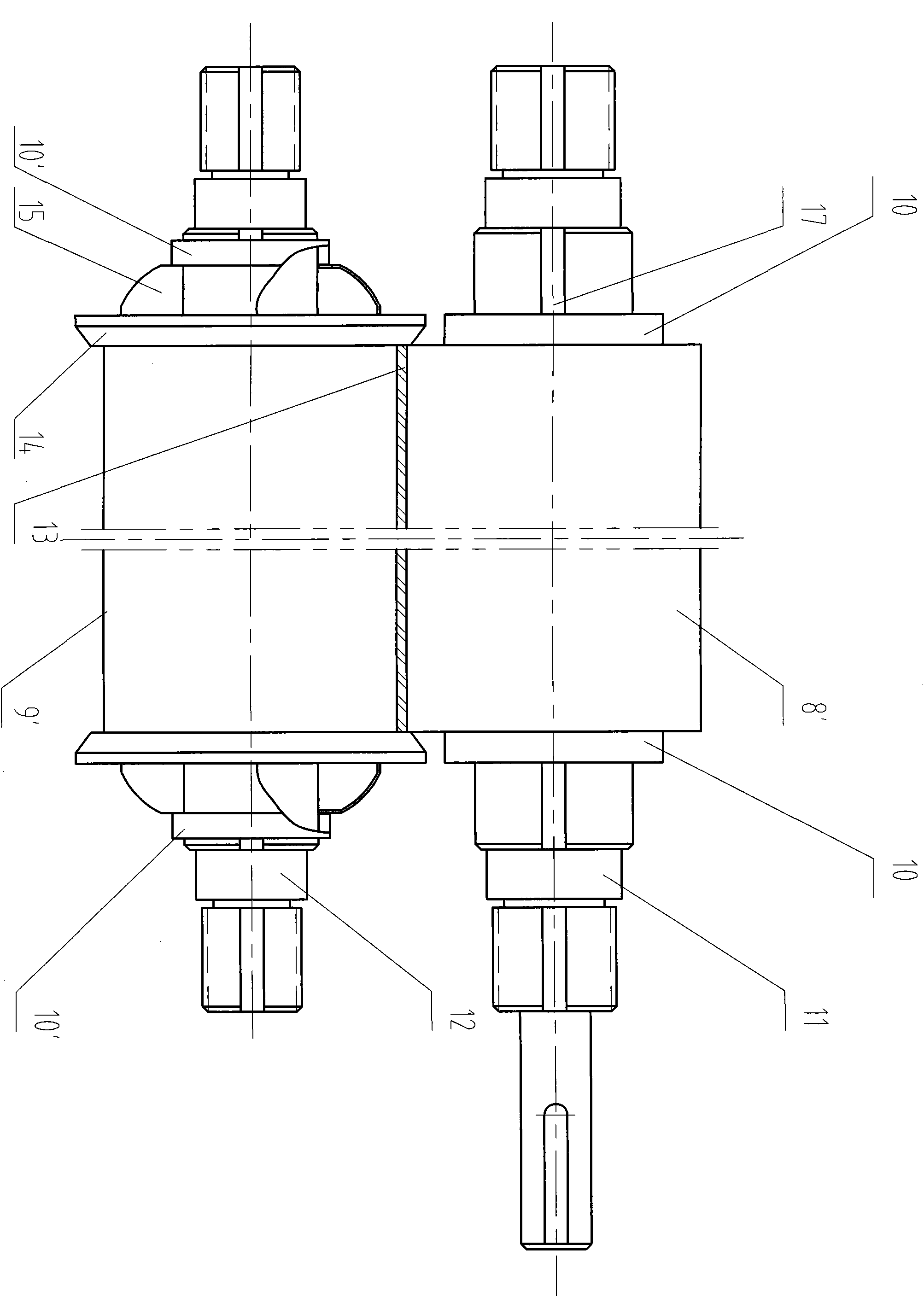

[0036] Such as Figure 1-3 As shown, the pinch roller type forced centering device consists of a base 1, an open frame 2 (lined sliding guide rail), an upper connecting fixed plate 4, a first lifting cylinder 5a and a second lifting cylinder 5b, and a synchronous rack and pinion 3 It is composed of upper and lower pinch type centering rollers (including upper roller 8 and lower roller 9). Wherein the upper roller 8 is a driving roller, and the lower roller 9 is a driven roller. The centered steel strip 13 is between the upper roll 8 and the lower roll 9 .

[0037] The upper roller 8 includes: the first upper roller bearing seat 7a and the second upper roller bearing seat (the second upper roller bearing seat has the same structure as the first upper roller bearing seat, corresponding to t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com