High frequency large flow 2D digital servo valve

A digital servo and high-flow technology, applied in servo motor components, fluid pressure actuators, mechanical equipment, etc., can solve the problems of insufficient dynamic characteristics, poor anti-pollution ability, complex structure, etc., and achieve simple structure and anti-pollution The effect of strong ability and low precision requirement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

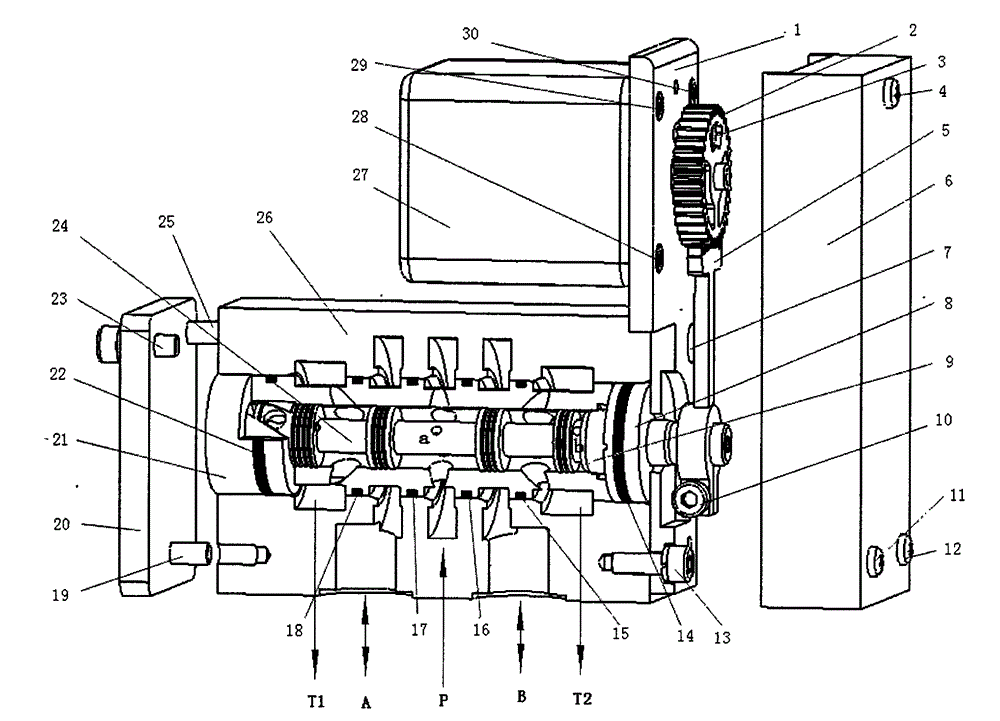

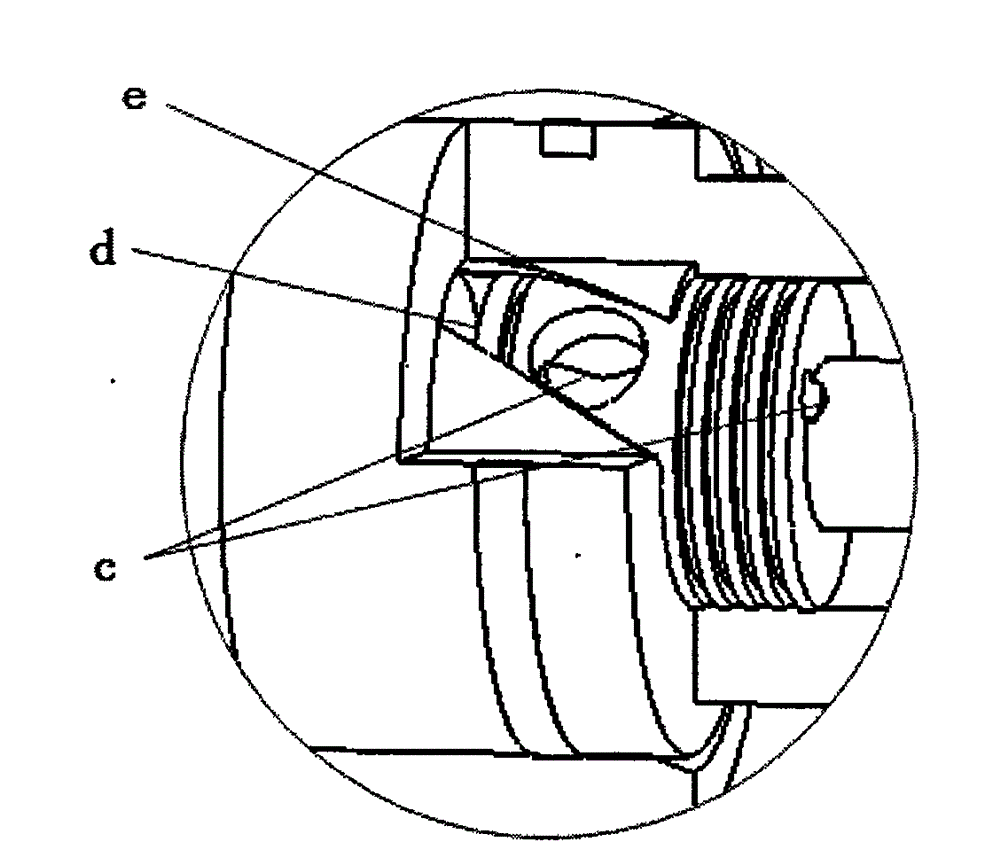

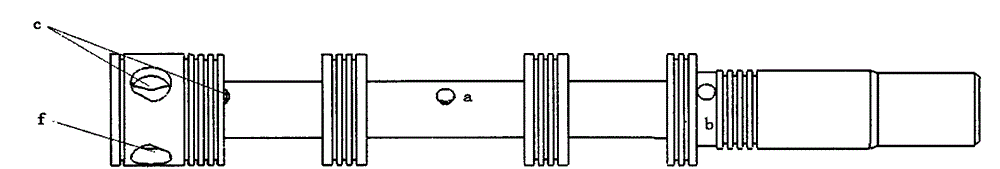

[0025] refer to Figure 1 to Figure 5 , a high-frequency and large-flow 2D digital servo valve, including a multi-pole AC servo motor 27, a torque amplification mechanism, a servo screw mechanism, a limit pin 3, a valve body 26, a rear cover plate 20, a box cover 6, and a right plug ring 8 , Concentric ring 9, motor mounting plate 1, O-rings 14, 15, 16, 17, 18, 22 and screws 4, 10, 11, 12, 13, 19, 23, 25, 28, 29, 30.

[0026] The multi-pole AC servo motor 27 is used as an electro-mechanical converter for driving the digital valve, located on the upper end of the valve body 26, and connected with the motor mounting plate 1 through screws 28, 29, 30. The box cover 6 is connected to the motor mounting plate 1 by screws 4, 11, 12.

[0027] The torque amplifying mechanism includes a gear 2 and a balance wheel 5. The gear 2 is press-fitted on the extended shaft of the mult...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com