Testing device and testing method for engineering mechanical properties of falling rock backfill

A technology of engineering mechanics and testing device, which is applied in the direction of using stable tension/pressure to test the strength of materials and preparation of samples for testing, etc. high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

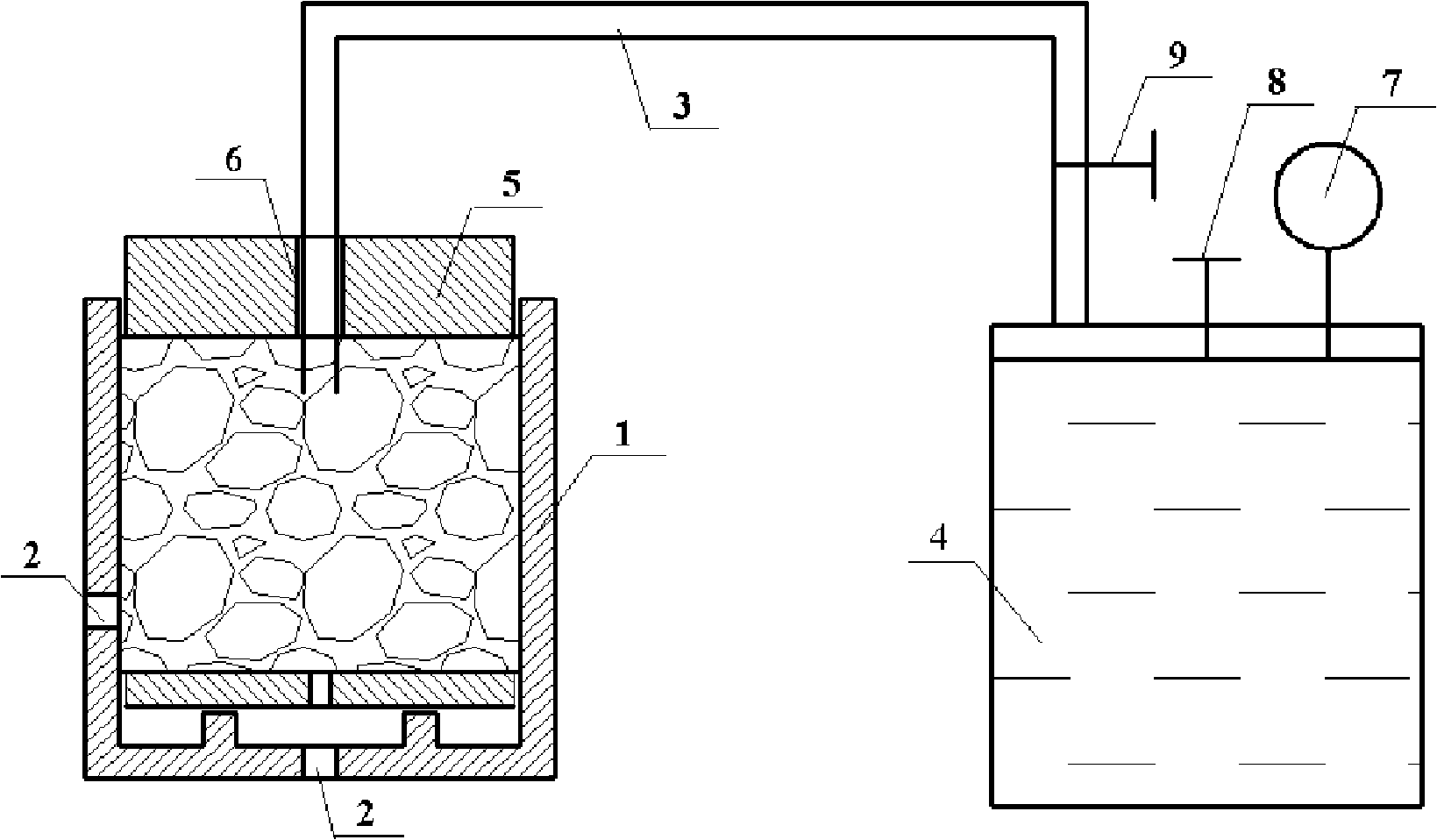

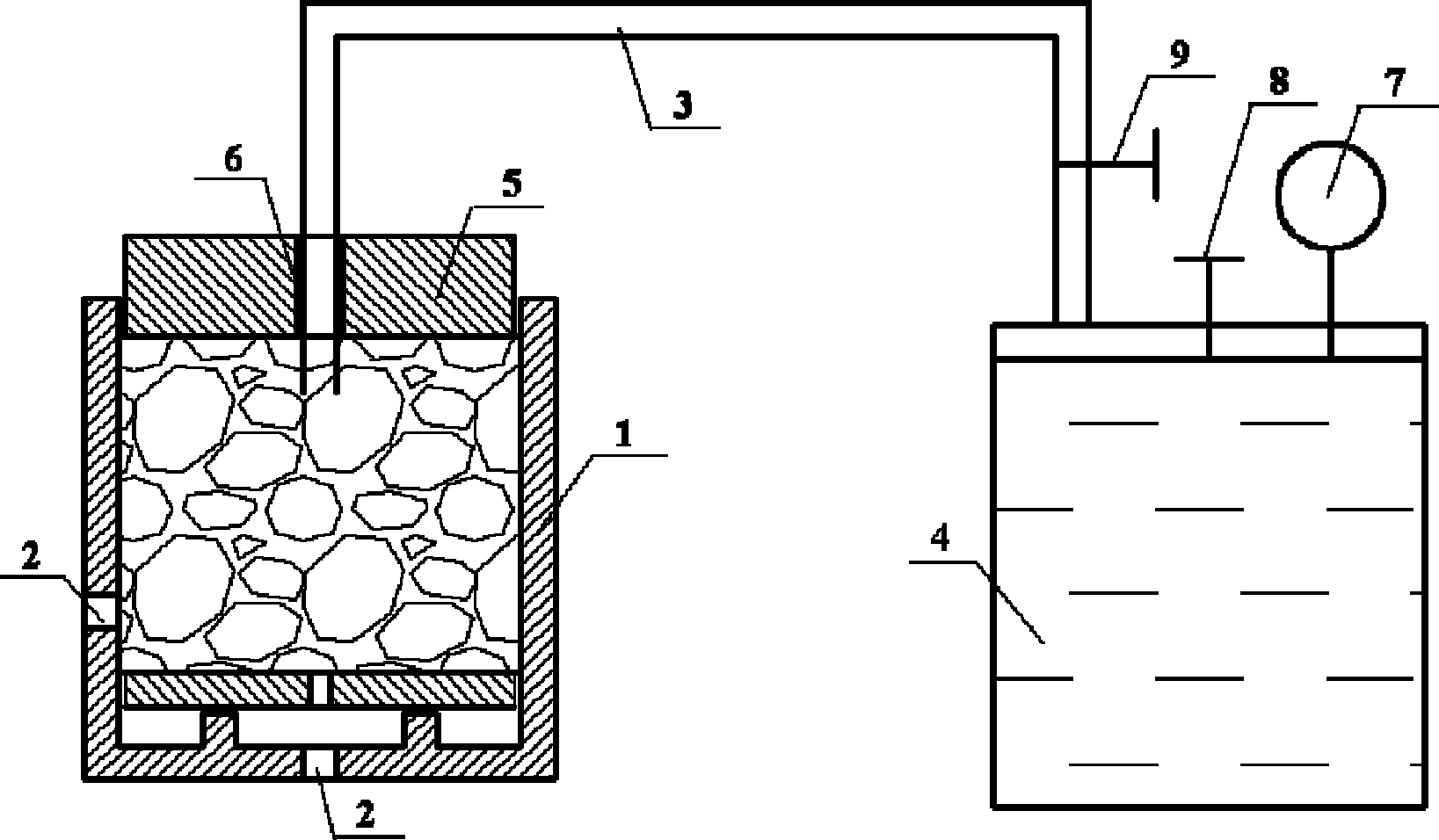

[0020] A testing device for the engineering mechanical properties of a grouting filling body, comprising a container 1, characterized in that: a drain port 2 is provided at the bottom or on the side of the container, and a filling slurry input pipe 3 is provided on the container, and the filling The slurry input pipe communicates with the slurry output device 4 .

[0021] The container is provided with a compacting cover plate 5, and the compacting cover plate is provided with a slurry input pipe installation port 6.

[0022] The slurry output device is provided with a pressure gauge 7 and a pressurizing valve 8, and the filling slurry input pipe is provided with a flow control valve 9.

[0023] A method for testing the engineering mechanical properties of a grouting filling body with gangue, characterized in that it is carried out according to the following steps:

[0024] 1) Process rock samples. In order to study the deformation characteristics of the grouted filling body ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com