Photoelectric friction coefficient tester

A friction coefficient, measuring instrument technology, used in instruments, measuring devices, mechanical devices, etc., can solve the problems of inability to realize dynamic testing, errors, inaccurate sliding lengths, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Specific embodiments of the present invention will be described below with reference to the accompanying drawings.

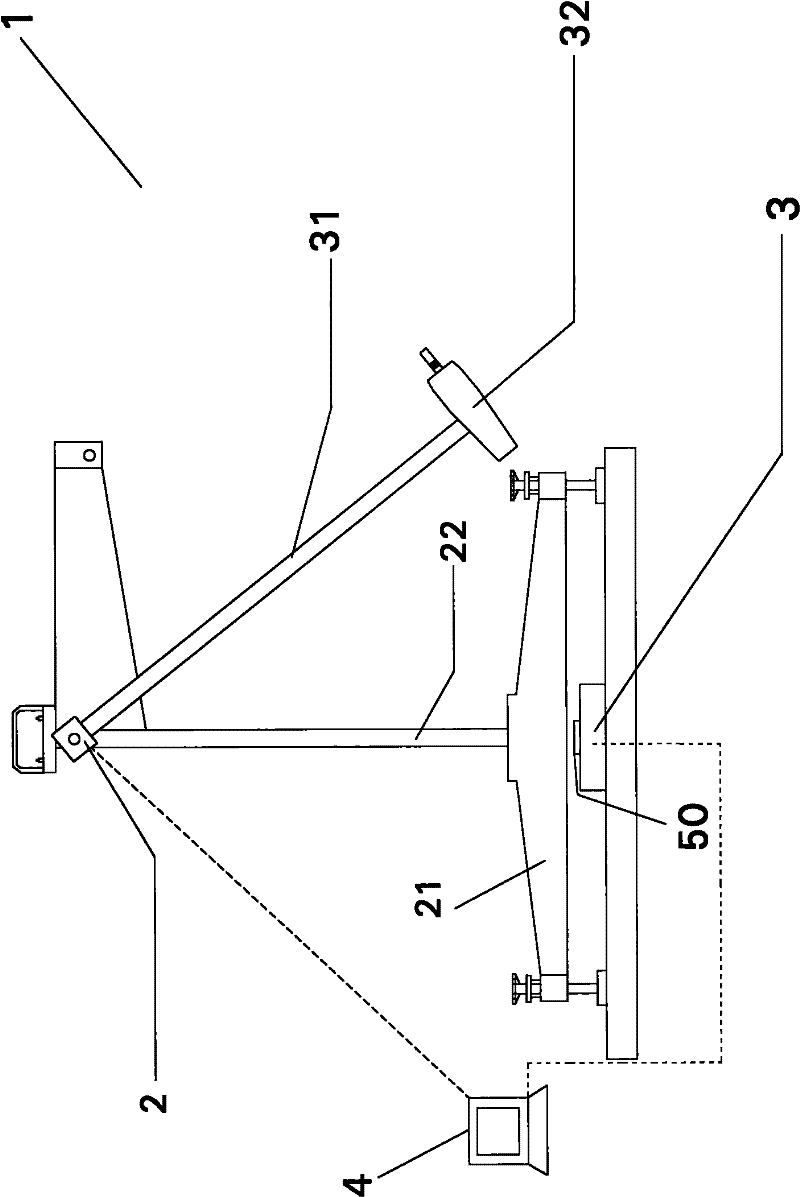

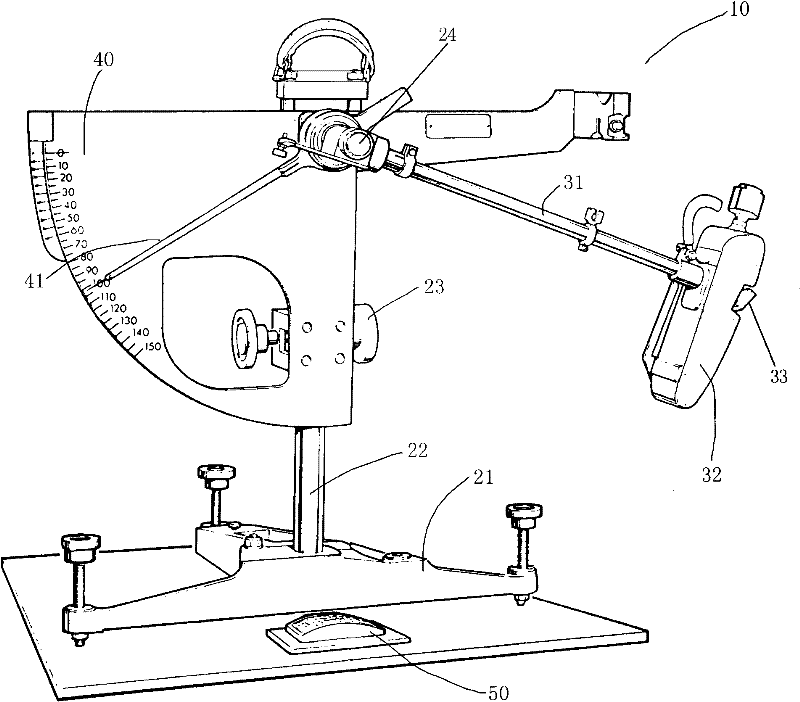

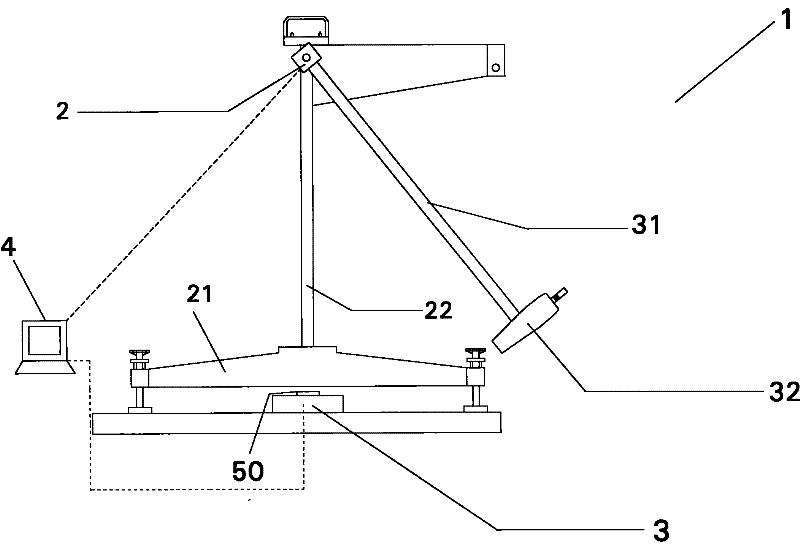

[0021] figure 1 It is a front view of the photoelectric friction coefficient measuring instrument 1 of the present invention. in the figure 1 in, right with figure 2 The same components in the prior art shown in , are labeled with the same reference numerals, since these components are basically the same in structure and function in the prior art, and have been described in the background technology section above, so they are omitted here A detailed description of it. Such as figure 1 As shown, the photoelectric friction coefficient measuring instrument 1 has: a main body support, a pendulum, an angle encoder 2 , a specimen holder 50 , and a force sensor 3 . The main body support includes a base 21 and a column 22 fixed on the base 21. The base 21 is fixed on the ground or table by a plurality of leveling screws, and the height of each point can b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com