Terminal point for connecting a ring terminal to an electrical device

A technology of electrical equipment and connection points, applied in the direction of conductive connection, electrical component connection, connection, etc., can solve complex problems, achieve low cost, save space, and simplify the connection difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

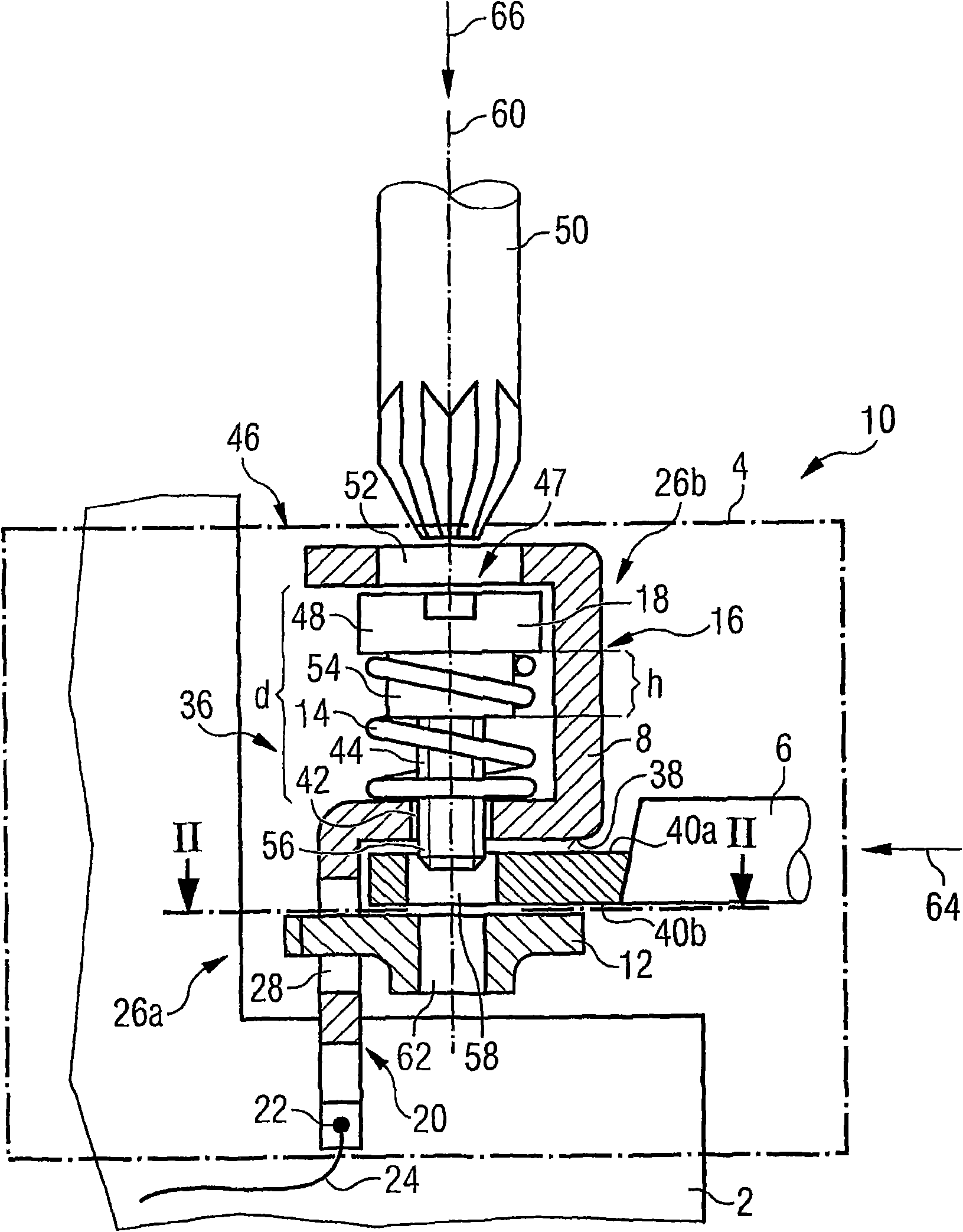

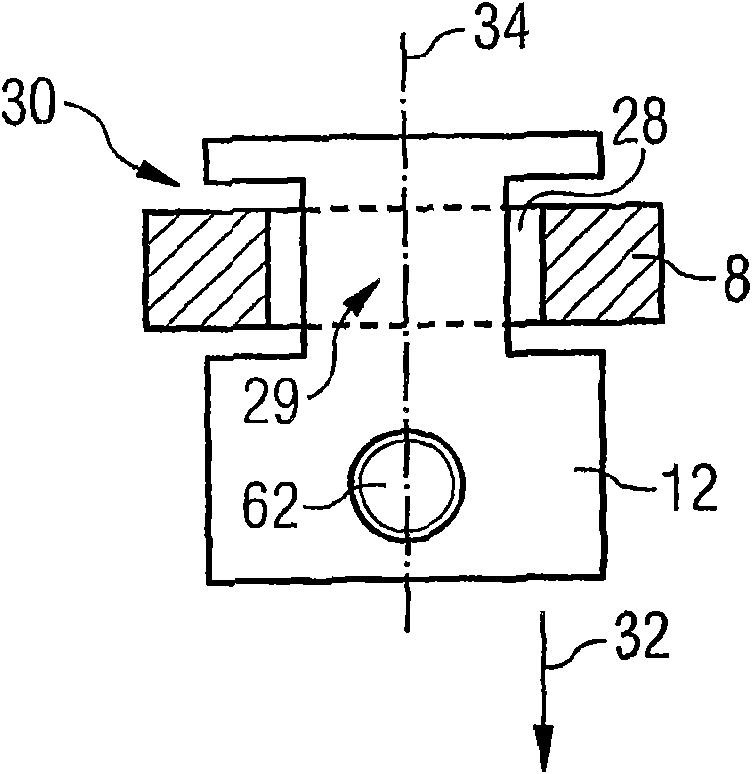

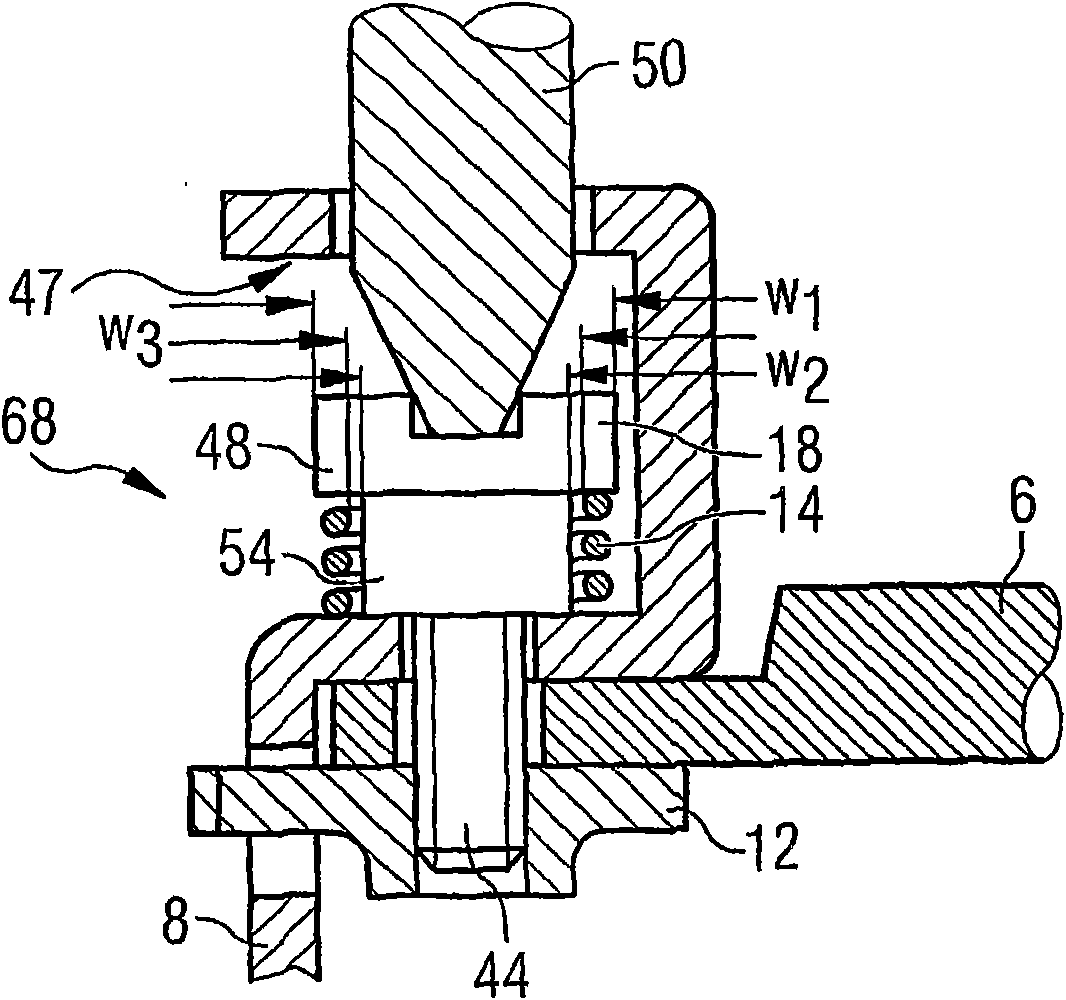

[0026] figure 1 The electrical device shown is a contactor 2 which includes a terminal 4 for a ring cable lug 6 on which an external lead (not shown in the figure) is crimped. The terminal 4 includes a bus bar or a contact holder 8 used as a connecting member and a clamping device 10 that is non-detachably mounted on the bus bar or the contact holder. The clamping device includes a threaded rail 12 used as a clamping plate and a clamping screw 18 that cooperates with the threaded rail, and the clamping screw is placed in position by a coil spring 14 figure 1 The release position 16 is shown.

[0027] The entire terminal 4 is installed in the contactor 2 with a fixed end 20 of the contact bracket 8, for example, encapsulated therein. The fixed end 20 is provided with a welding point 22 used as an equipment connector, and an internal connection wire 24 of the equipment is welded to the welding point, so that the terminal 4 is electrically connected to the inside of the equipment.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com