Liquid storing tank with fixed liquid discharge and atomizer with the liquid storing tank

A liquid storage tank and liquid output technology, applied in the field of atomizers, can solve the problems of very large deviation of liquid output and unsatisfactory atomization effect, and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

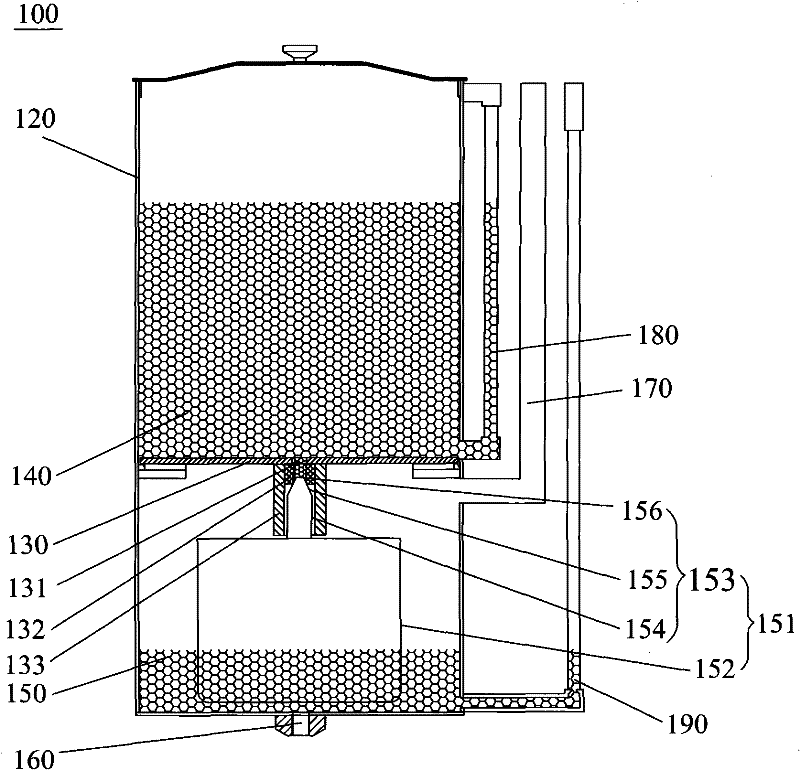

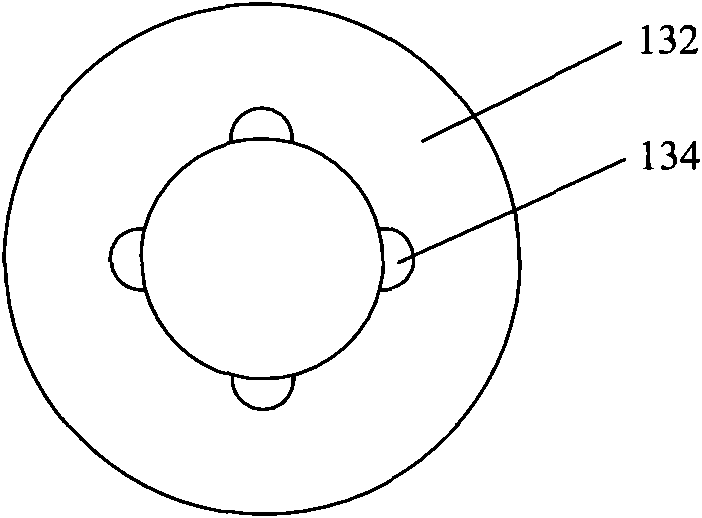

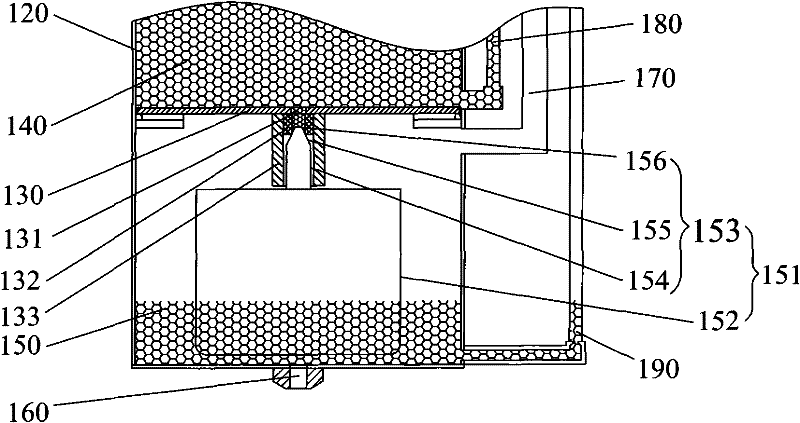

[0026] refer to figure 1 , a liquid storage tank 100 with a fixed liquid output volume, comprising a tank body 120, a tank cavity surrounded by the tank body, and a liquid outlet pipe 160 communicating with the tank cavity, and the tank cavity of the tank body is provided with There is a layer of separator 130, and the separator 130 divides the tank cavity into a liquid storage chamber 140 located at the upper part and a liquid outlet chamber 150 located at the lower part, and the liquid outlet pipe 160 is connected to the bottom of the liquid outlet chamber 150 and In communication with the liquid outlet chamber 150, a through hole 131 connecting the liquid storage chamber 140 and the liquid outlet chamber 150 is provided on the partition plate 130, and a floating roof is placed in the liquid outlet chamber 150 Object 151, the floating top 15...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com