A semi-wet high-voltage electrostatic precipitator electrode

A high-voltage electrostatic, semi-wet technology, applied in electrostatic separation, electrode cleaning, etc., can solve problems such as large water consumption, reduce water consumption and energy consumption, eliminate pollution, and reduce water consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

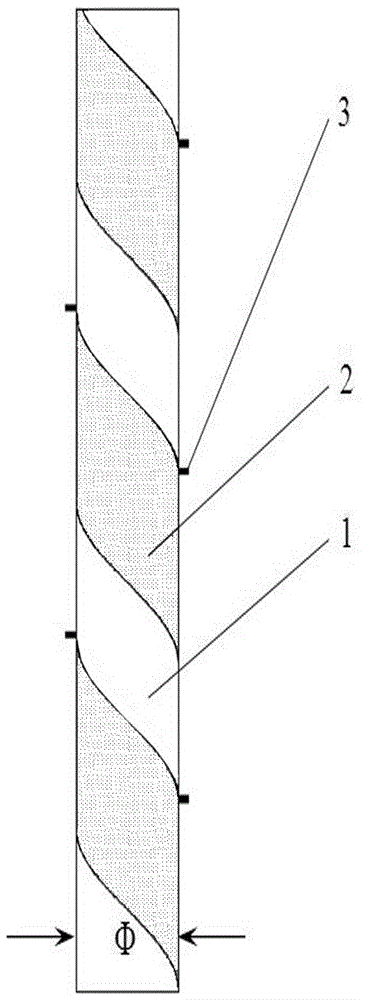

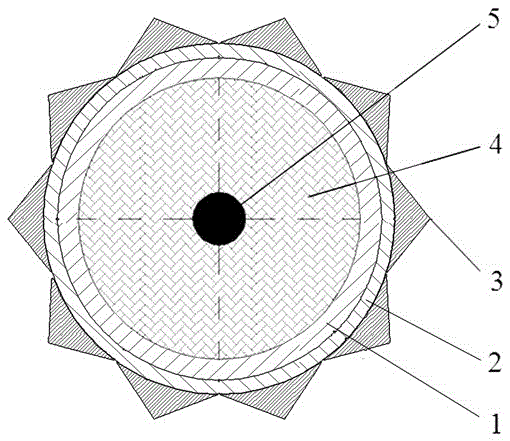

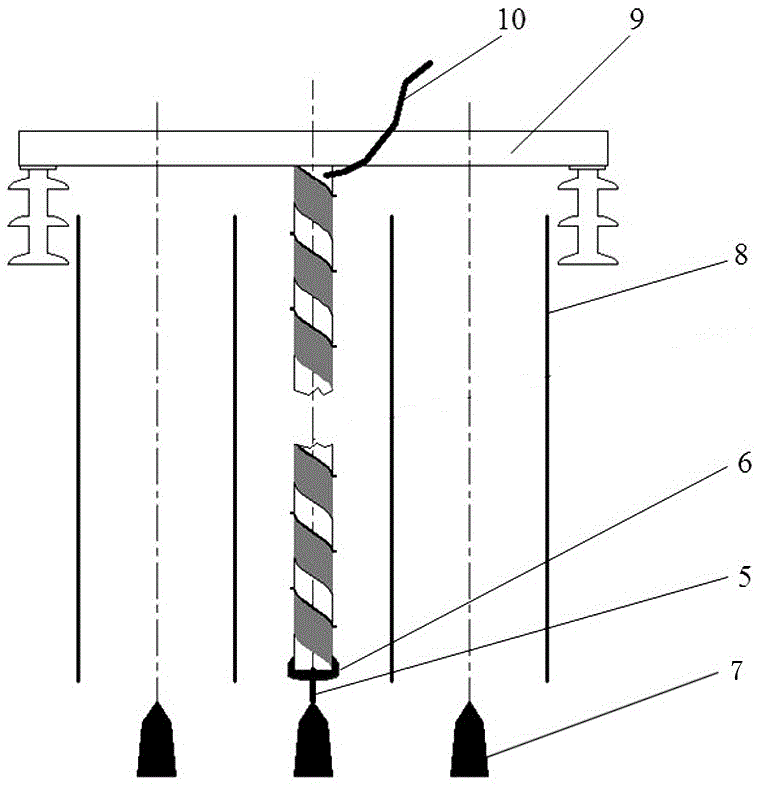

[0017] Such as figure 1 As shown, the present invention includes a central rope 5 , a water-absorbing fiber material layer 4 , a water-permeable fiber material layer 1 , a metal material layer 2 , a water delivery pipe 10 and a weight 7 .

[0018] Wherein, the upper end of the central rope 5 is fixed on the bracket 9, and is in a vertically suspended state, and a steel wire rope with a diameter within the range of 1 to 5 mm can be selected according to the length or weight of the electrode.

[0019] A water-absorbing fiber material layer 4 is coated on the periphery of the central rope 5. The water-absorbing material layer can be made of polymer water-absorbing resin SAP (commonly known as "diapers"), which is characterized by a very large water absorption capacity and water storage capacity. The upper end of the layer 4 is connected with a water delivery pipe 10 . The difference between the outer diameter and the inner diameter of the water-absorbing fiber material layer 4 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com