Online biaxial-orienting PVC extrusion molding mould

An extrusion molding, biaxially oriented technology, applied in the field of online biaxially oriented PVC extrusion molding die, can solve the problem that the strength and toughness of pipe products cannot be guaranteed, and achieve a wide-ranging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

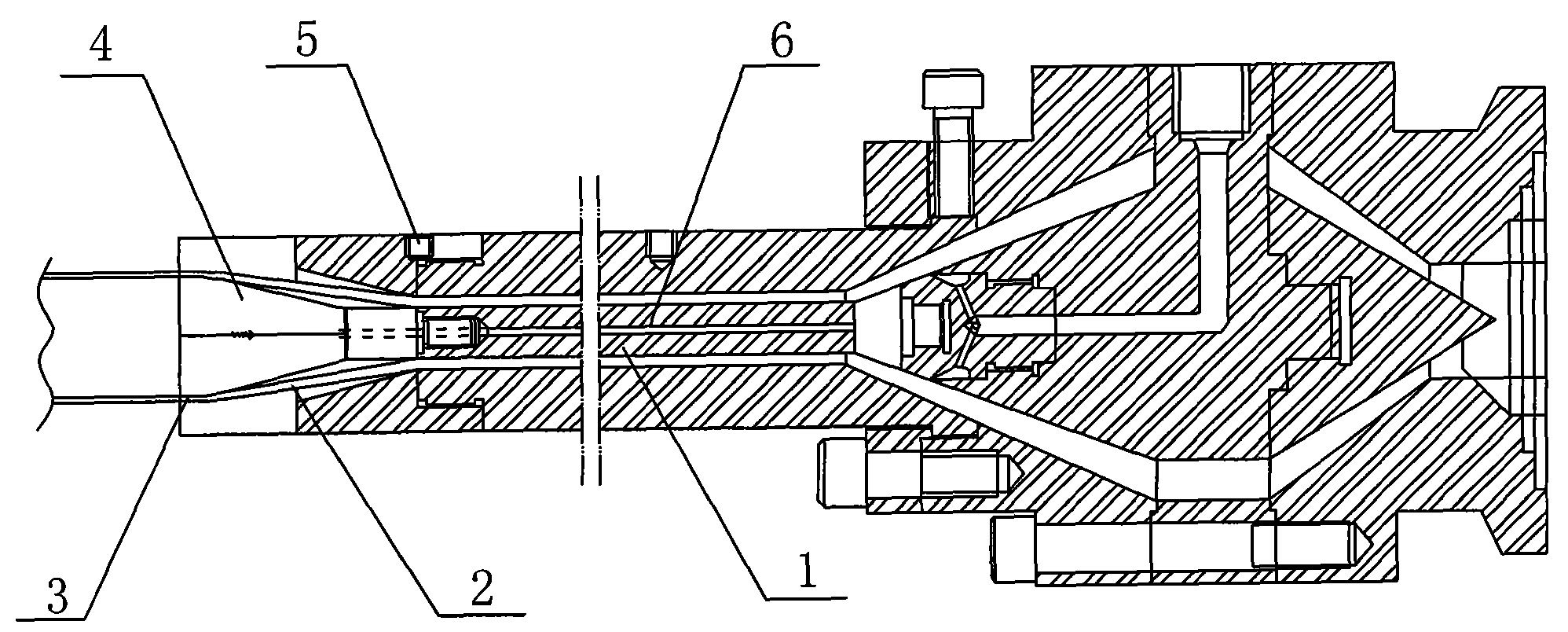

Embodiment 1

[0019] Example 1: Extrusion of DN200×4.4, PN1.0 online biaxially oriented pressure-bearing pipe. According to the specified formula, the materials will be mixed and added to the twin-screw extruder. Under the specified process conditions, they will be fully plasticized and extruded to enter the mold of the present invention. The materials will enter the tube embryo forming area after secondary compression 1. Expansion transition Zone 2, ring expansion forming zone 3, rapidly cooling and shaping under traction. The characteristic value of the mold: the compression ratio is 1: (8-9), the length of the straight section is (6-7) times the diameter of the tube blank, and the ratio of the section of the expanded tube to the section of the tube blank is 1: (1.20-1.25 ), the circumferential expansion ratio is ≥1:2, the expansion angle is (40-50)°; the stretching temperature is (135-145)°C, the temperature of the expansion medium is (120-130)°C, and the pressure is ( 10-20) kPa, the t...

Embodiment 2

[0020] Embodiment 2: the implementation process is the same as in embodiment 1, the characteristic value of the mould: the compression ratio is 1: (7-8), the length of the straight section is (7-8) times of the diameter of the tube embryo, and the cross-section of the pipe after expansion The section ratio to the tube embryo is 1:(1.25-1.30), the circumferential expansion ratio is ≥1:2, and the expansion angle is 35°; the stretching temperature is (130-140)°C, and the temperature of the expansion medium is (120 -135)°C, the pressure is (8-14)kPa, the temperature of the external cooling medium is room temperature, and the traction speed is (0.65-0.80)m / min. Main properties of the pipe: impact resistance, 0°C, 1h, 4kg×2m hammer head diameter 25mm, impact 25 times, no damage, TIR<10%; instantaneous burst pressure of the pipe is 3.6MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Stretch temperature | aaaaa | aaaaa |

| Burst pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com