Doubling device for packaging machinery

A technology of packaging machinery and folding devices, applied in packaging, transportation and packaging, container manufacturing machinery, etc., can solve the problems of easy to produce defective products, easy aging of pull hooks, low efficiency, etc., and achieve easy failure, no energy consumption, The effect of fewer defective products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

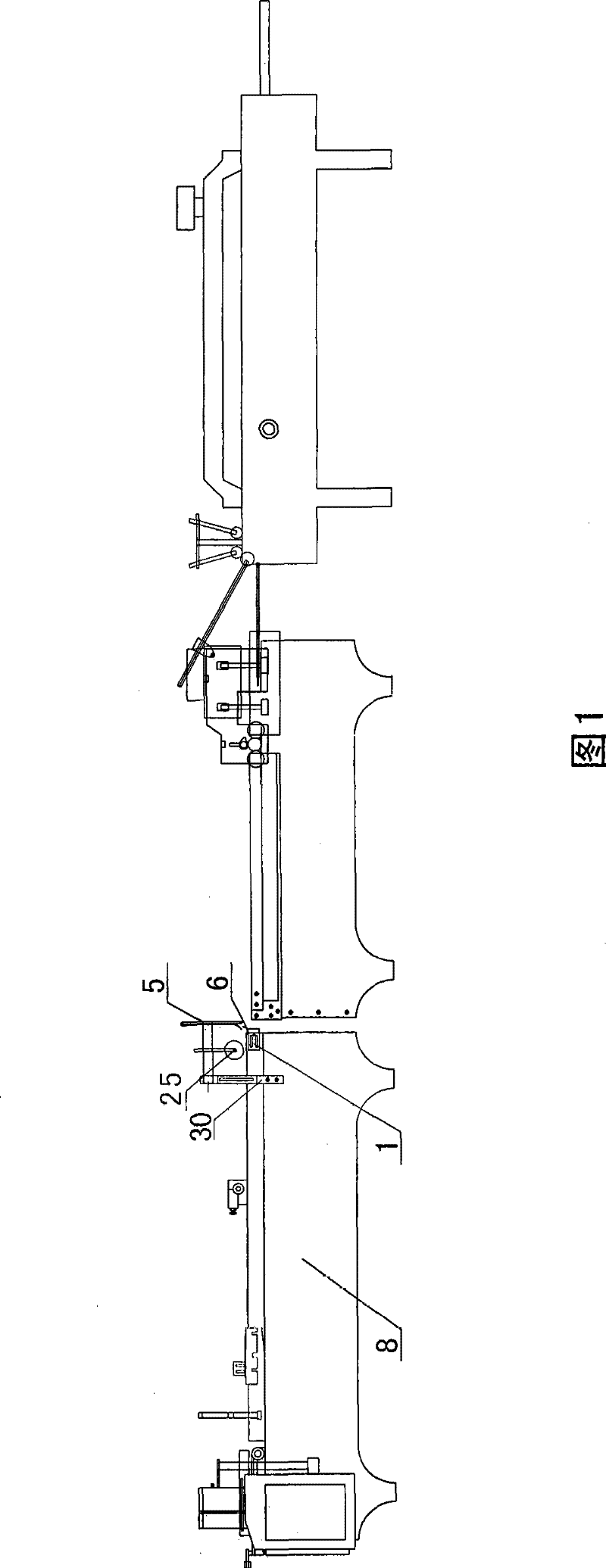

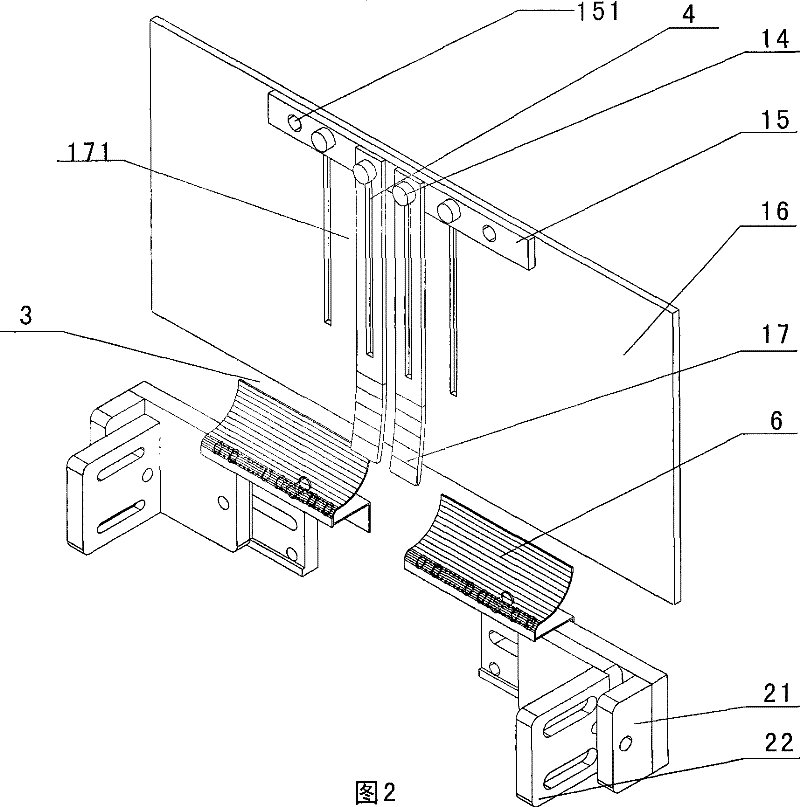

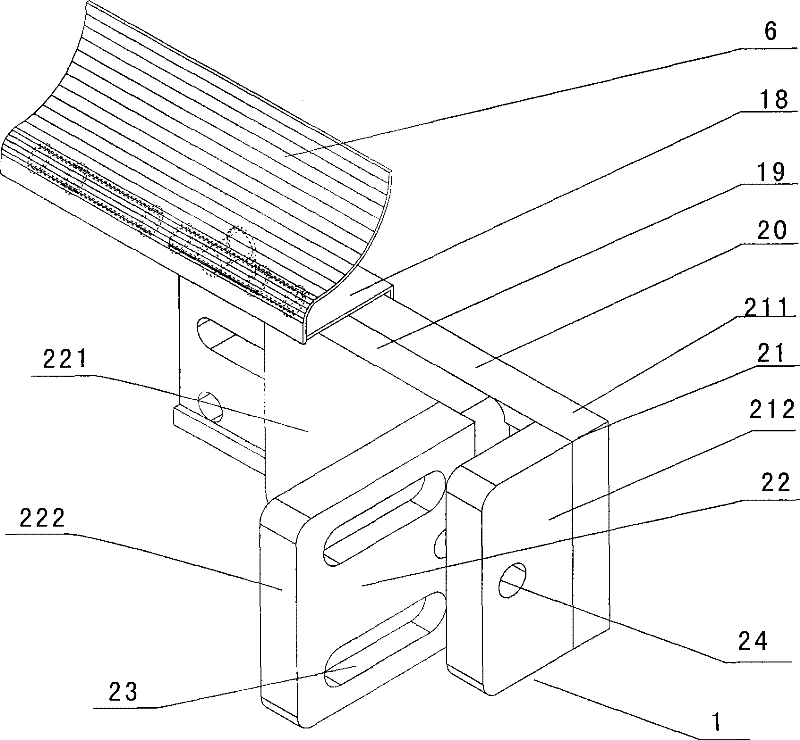

[0014] Such as Figure 1-Figure 4 As shown, the present invention is a half-folding device used on a packaging machine, which includes adjustment devices 1 symmetrically fixed on both sides of the conveyor belt for conveying packages, and an arc-shaped elastic plate 6 connected above each adjustment device 1, and The folding device 5 corresponding to the elastic plate 6 is provided with an upper pressing wheel 25 directly in front of the elastic plate 6 to prevent the package from bulging, and the upper pressing wheel 25 is fixed on the base 8 through a bracket 30. In order to make the package enter smoothly In the folding device 5, the lower edge of the elastic plate 6 is preferably designed to be slightly upturned.

[0015] Such as figure 2 As shown, the folding device 5 includes a blocking plate 16 , a pressing piece 17 and a paper blocking slider 15 . In this example, in order to make the packaging body enter the folding groove 171 of the pressing piece 17 and advance i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com