elevator equipment

A technology for elevators and equipment, used in elevators, lifts, transportation and packaging in buildings, etc., can solve the problems of rising manufacturing costs, reinforcement, and the height must be set below the top beam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Embodiments of the present invention will be described below with reference to the drawings.

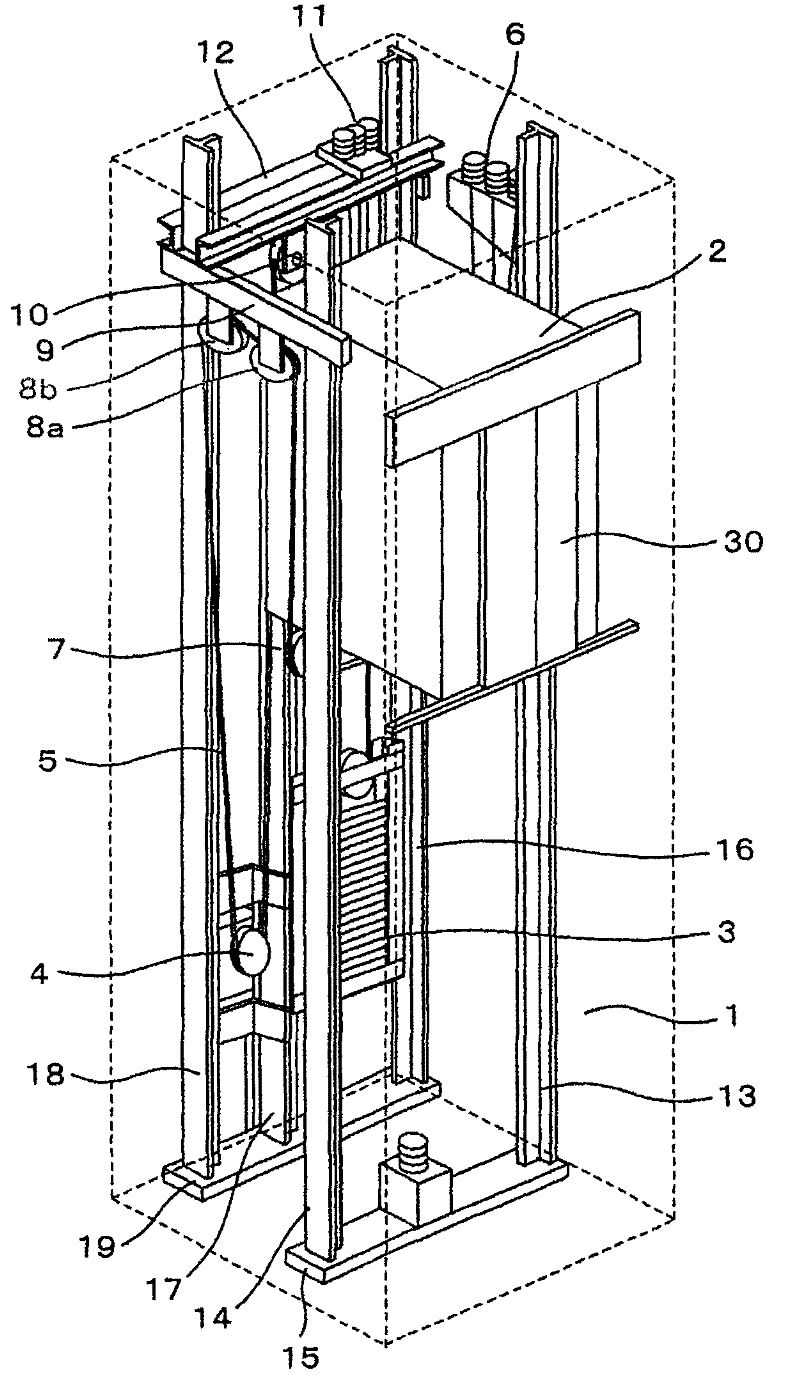

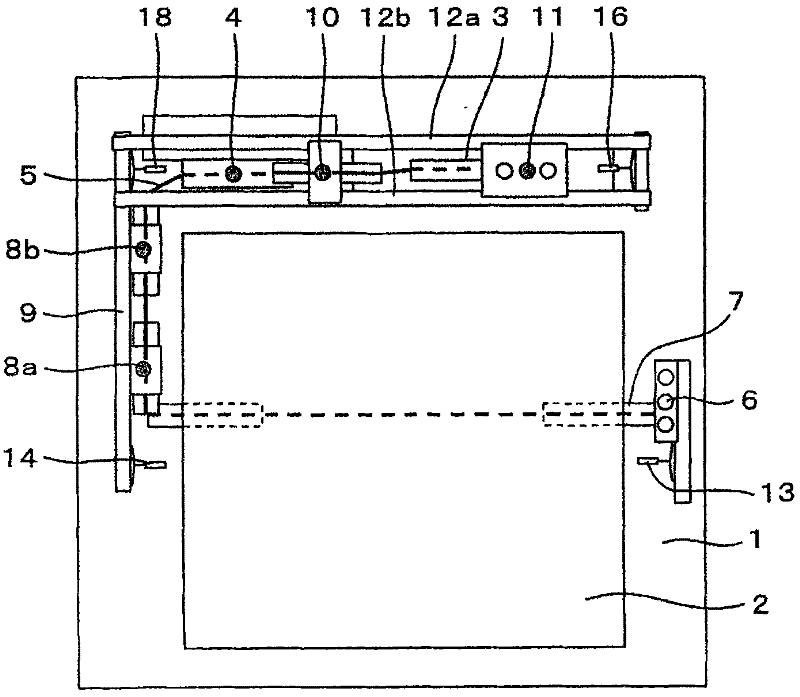

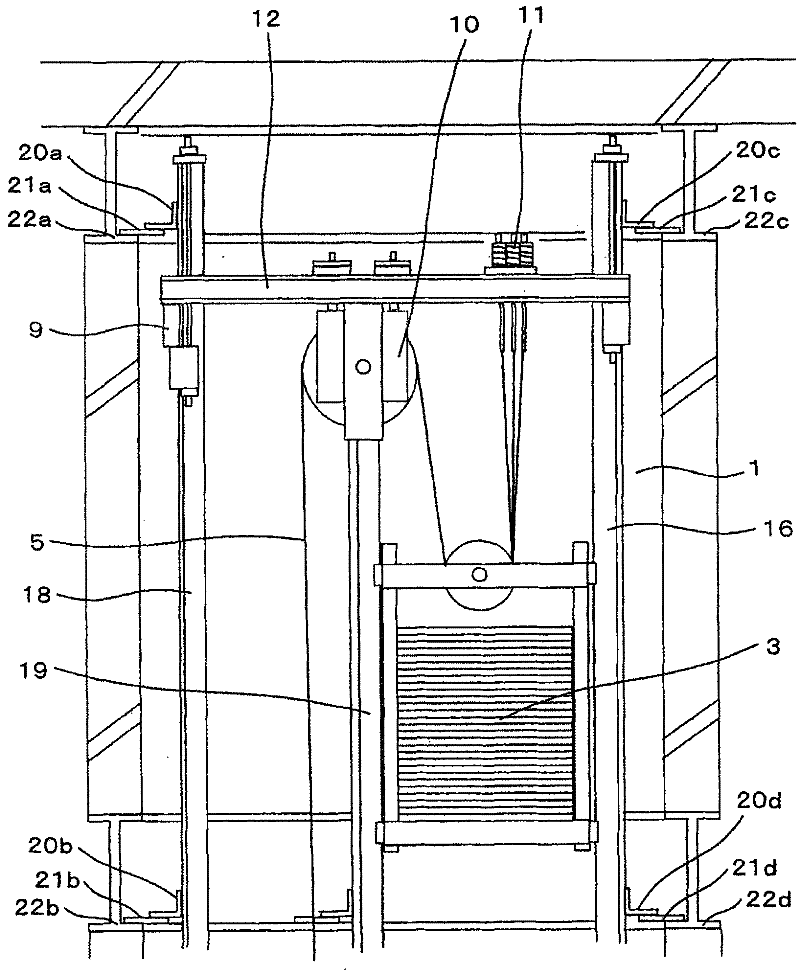

[0038] figure 1 It is a perspective view showing the outline of one embodiment of the elevator equipment of the present invention, figure 2 is a top view, image 3 It is a sectional view near the uppermost layer.

[0039] figure 1 The elevator shown is an elevator without a machine room formed in the hoistway 1 of the elevator. The sling 5 extends downward from the end of the main sling installed on the main sling fixing base 6 on the side of the elevator car and is wound around the lower car sheave 7 of the elevator car 2, and then returns upward to Suspend the elevator car 2, and then wind it on the elevator car side top sheave 8a, 8b (the elevator car side top sheave 8a, 8b is arranged on the elevator car side top beam 9 at the top of the hoistway) The upper and rear turns to extend downwards, and are wound on the sheave of the hoist 4 near the bottom floor, and then ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com