Observation method of silver/titanium/steel brazed joint welding interface metallographic structures

A technology of welding interface and metallographic structure, which is applied in the preparation of test samples and material analysis using radiation, etc. It can solve problems such as difficult to obtain joint interface structure with clear interface, and achieve the effect of easy operation and good observation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

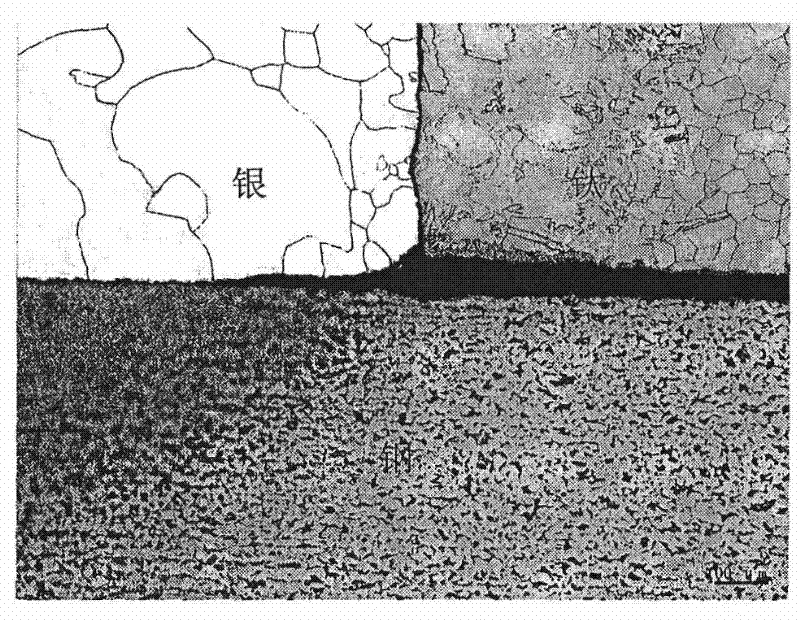

[0028] The method of displaying the metallographic structure of the interface of pure silver brazing filler metal argon arc welded joints in the atmosphere of pure titanium plate with a thickness of 3mm and Q235 steel plate with a thickness of 8mm. It is characterized in that a plane is machined on the surface of the silver / titanium / steel brazed joint sample to be observed, and the processed sample is first used on a grinding machine with 150 # , 700 # , 1000 # Grinding with metallographic water sandpaper, the samples after grinding are washed with sand grains, the samples are pickled with 10% HF solution, and then polished on a polishing machine. The polished samples are first selected with a volume ratio of HNO. 3 : mixed solution of HCl=1:1, soak the sample for 3s, in which HNO 3 The volume percentage concentration is 2%; then use 100mlK 2 Cr 2 O 7 Saturated solution, 1mlH 2 SO 4 The silver was wiped with a mixed reagent consisting of 1ml saturated NaCl solution, and...

Embodiment 2

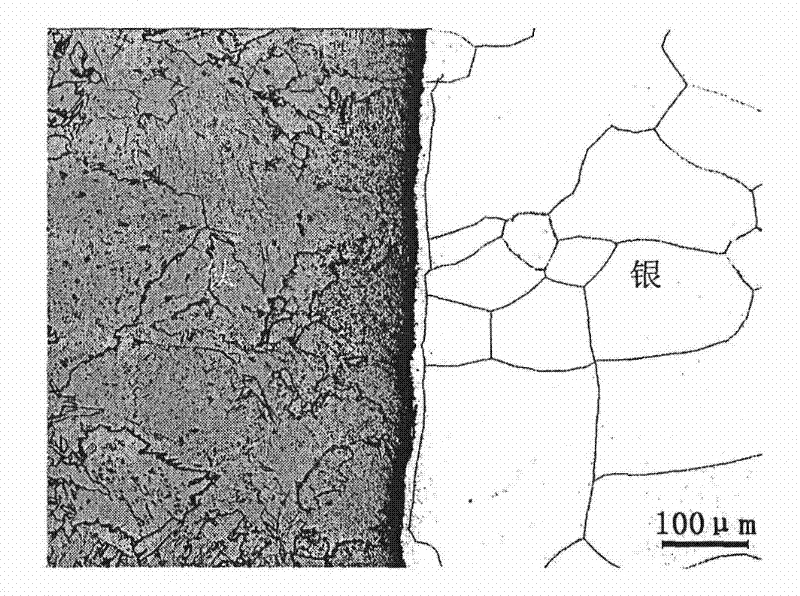

[0030] The method of displaying the metallographic structure of the interface of pure silver brazing filler metal argon arc welded joints in the atmosphere of pure titanium plate with thickness 3mm and 16MnR steel plate with thickness 8mm. It is characterized in that a plane is machined on the surface of the silver / titanium / steel brazed joint sample to be observed, and the processed sample is firstly processed on a grinding machine with 150 # , 700 # , 1000 #Grinding with metallographic water sandpaper, the samples after grinding are washed away the sand particles, after the samples are pickled with 15% HF solution, they are polished on a polishing machine. The polished samples are first selected with a volume ratio of HNO 3 : mixed solution of HCl=1:1.5, soak the sample for 4s, in which HNO 3 The volume percentage concentration is 4%; then use 100mlK 2 Cr 2 O 7 Saturated solution, 3mlH 2 SO 4 The silver is wiped with a mixed reagent composed of 2ml saturated NaCl solut...

Embodiment 3

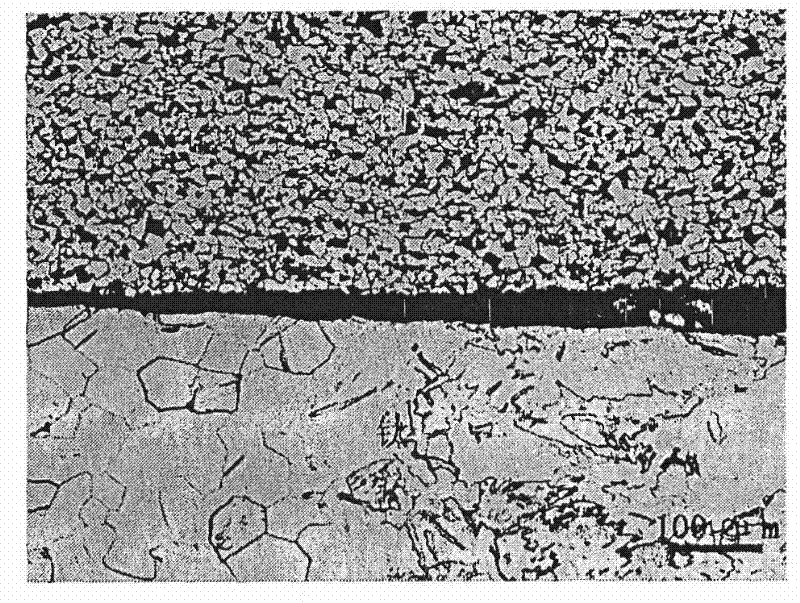

[0032] A method for displaying the metallographic structure of the interface of TA2 titanium plate with a thickness of 1mm and a Gr70 steel plate with a thickness of 3mm in the atmosphere of pure silver brazing filler metal argon arc welded joints. It is characterized in that a plane is machined on the surface of the silver / titanium / steel brazed joint sample to be observed, and the processed sample is firstly processed on a grinding machine with 150 # , 700 # , 1000 # Grinding with metallographic water sandpaper, the samples after grinding are washed away the sand particles, after the samples are pickled with 20% HF solution, they are polished on a polishing machine. The polished samples are first selected with a volume ratio of HNO 3 : mixed solution of HCl=1:2, soak the sample for 6s, in which HNO 3 The volume percentage concentration is 5%; then use 100mlK 2 Cr 2 O 7 Saturated solution, 5mlH 2 SO 4 Wipe the silver with a mixed reagent consisting of 3ml saturated NaCl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com