Methods and systems for composite structural truss

A technology of interconnected structure and truss structure, which is applied in the direction of chord/longeron, wing, transportation and packaging, etc., and can solve problems such as difficult assembly and complex manufacturing of composite ribs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] [0012] The following detailed description illustrates the disclosure by way of illustration and not limitation. Obviously, this description will enable one skilled in the art to make and use the disclosure, describes several embodiments, adaptations, changes, substitutions and uses of the disclosure, including what is presently considered the best mode of the disclosure.

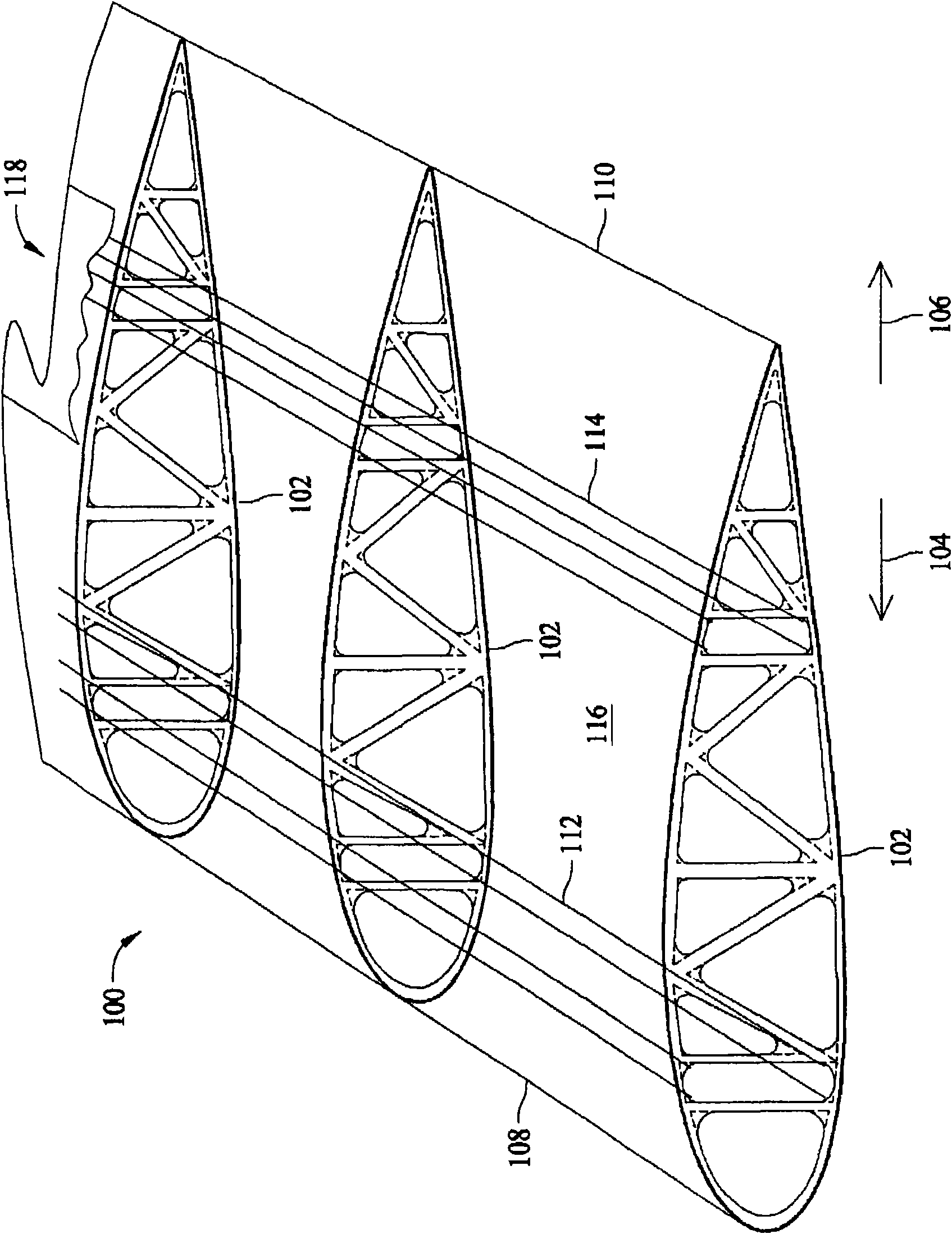

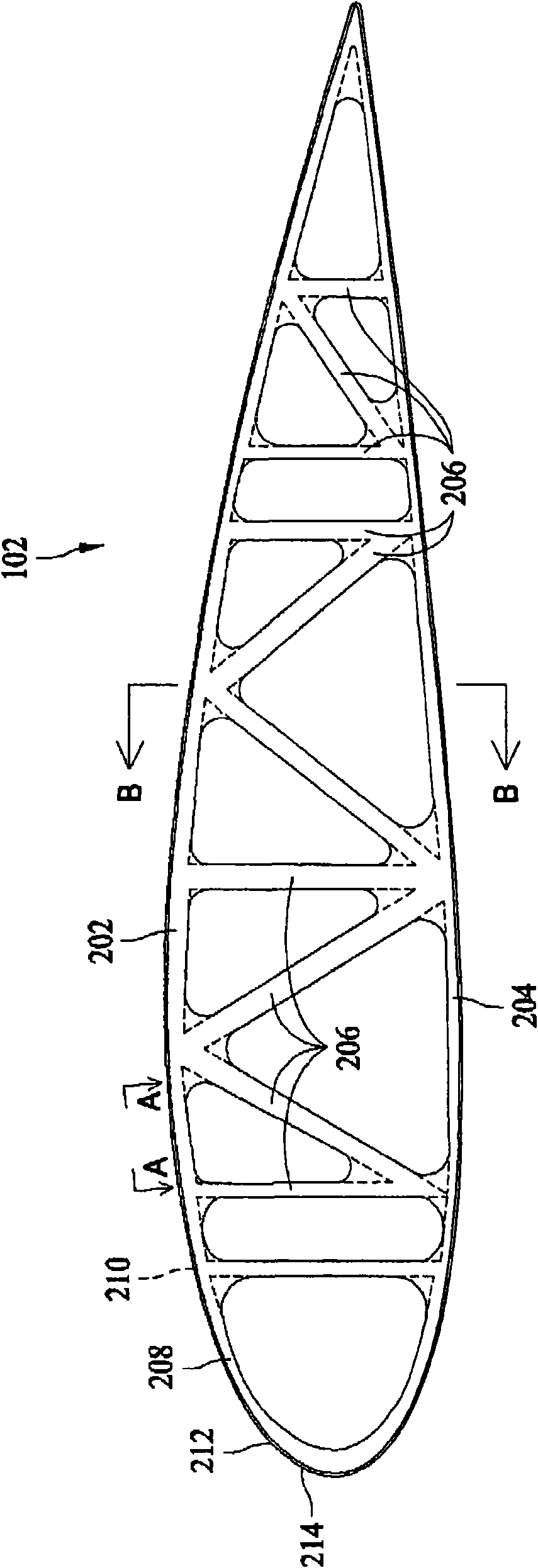

[0013] 【0013】 figure 1 is an isometric cross-sectional view of an airfoil structure 100 according to an embodiment of the disclosure. In the exemplary embodiment, wing structure 100 includes a plurality of truss rib assemblies 102 extending forward 104 and aft 106 between leading edge 108 and trailing edge 110 of wing structure 100 . The wing structure 100 also includes a front spar 112 and a rear spar 114 extending from the fuselage (not shown) of the aircraft. Lower wing skin 116 is attached to the lower portion of truss rib assembly 102 between leading edge 108 and trailing edge 110 . Similarly,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com