Compressing head of trash compressing box

A technology of garbage compression and compression head, applied in the field of compression head, can solve the problems of affecting the reliability of the device, difficult to collect garbage in the center, affecting the loading capacity of the box, etc., and achieve the effects of not easy partial load, reasonable distribution, and balanced force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

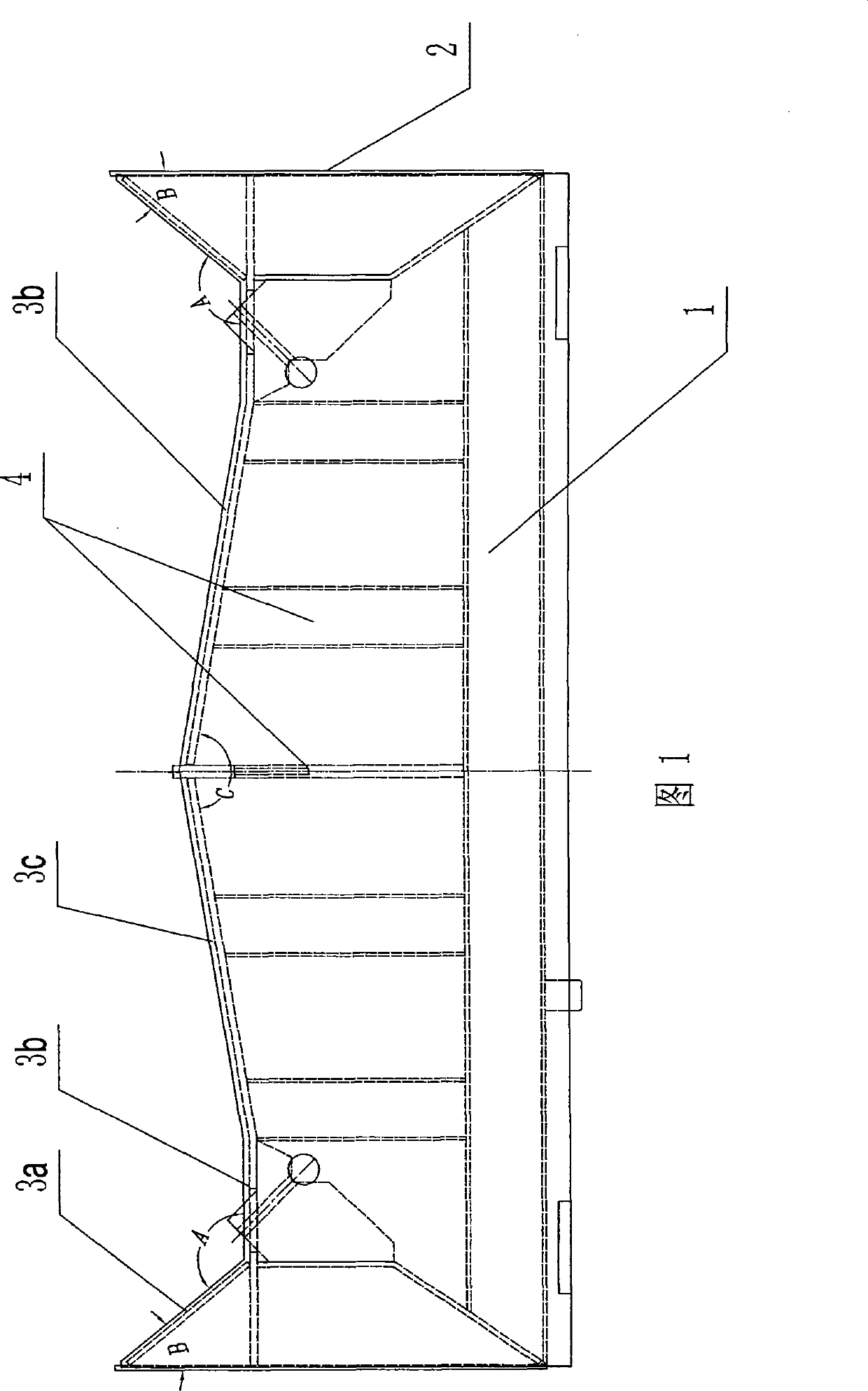

[0007] As shown in the figure, it is the compression head of the garbage compression box, which includes a compression head support mechanism 1 and a compression panel. The support mechanism 1 includes side plates 2 parallel to each other on both sides and several support plates 4 arranged between the side plates 2. Plate 2 and support plate 4 are all connected with the compression panel, and the support plate 4 acts as a strengthening structure. The compression panel is formed by connecting the side compression plate 3a, the transition compression plate 3b and the middle compression plate 3c, and the side compression plate 3a, the transition compression plate 3b and the middle compression plate 3c are equipped with a pair symmetrically left and right, wherein, the angle B between the side compression plate 3a and the side plate 2 is 35-45°, and the angle B between the two middle compression plates 3c The angle C is 155-165°, the angle A between the transition compression plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com