Vacuum sucking disc carrying module

A technology of vacuum suction cups and suction cups, applied in the direction of furnace components, transportation and packaging, conveyor objects, etc., can solve problems such as only suitable for handling single-size plates, stress concentration, etc., and achieve the effect of improving stress concentration and simple structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

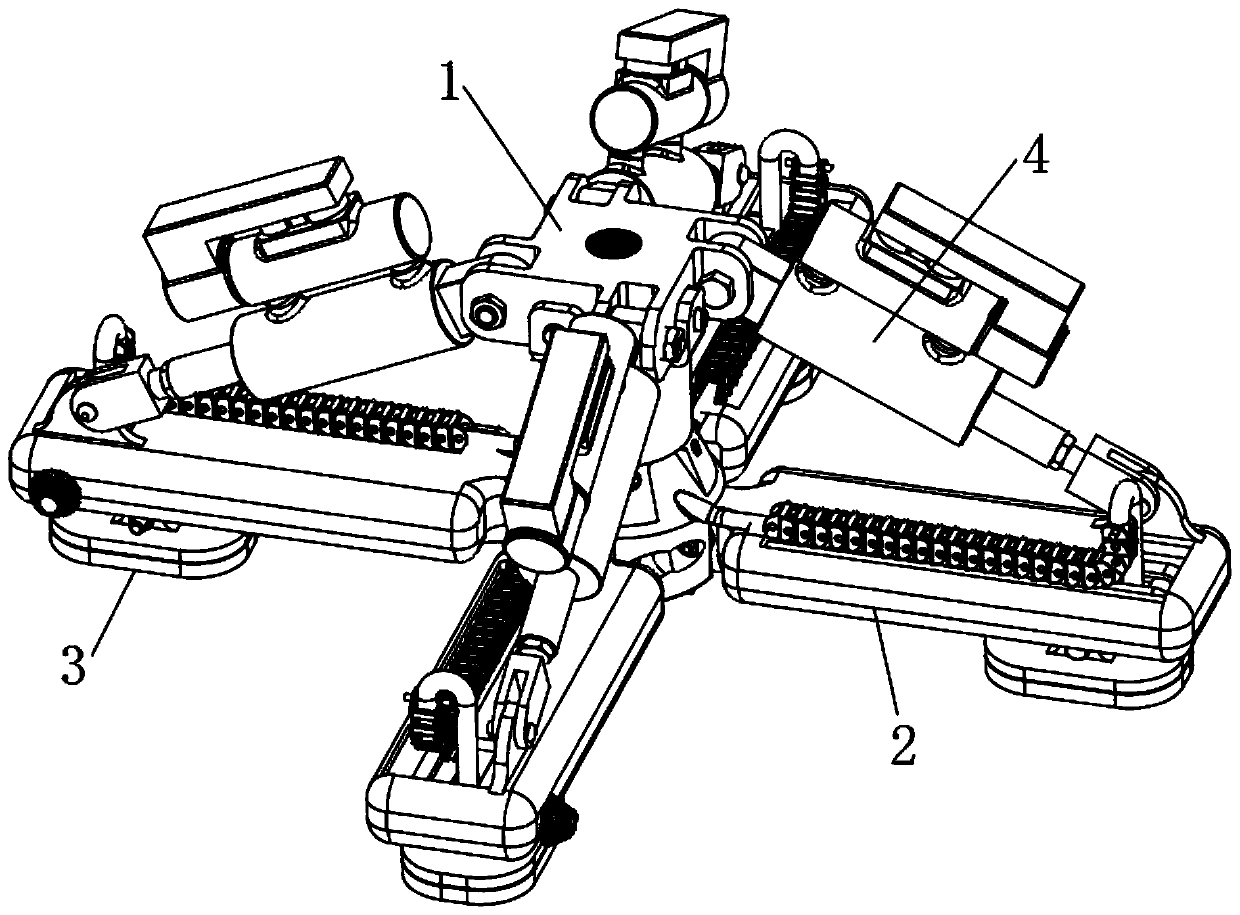

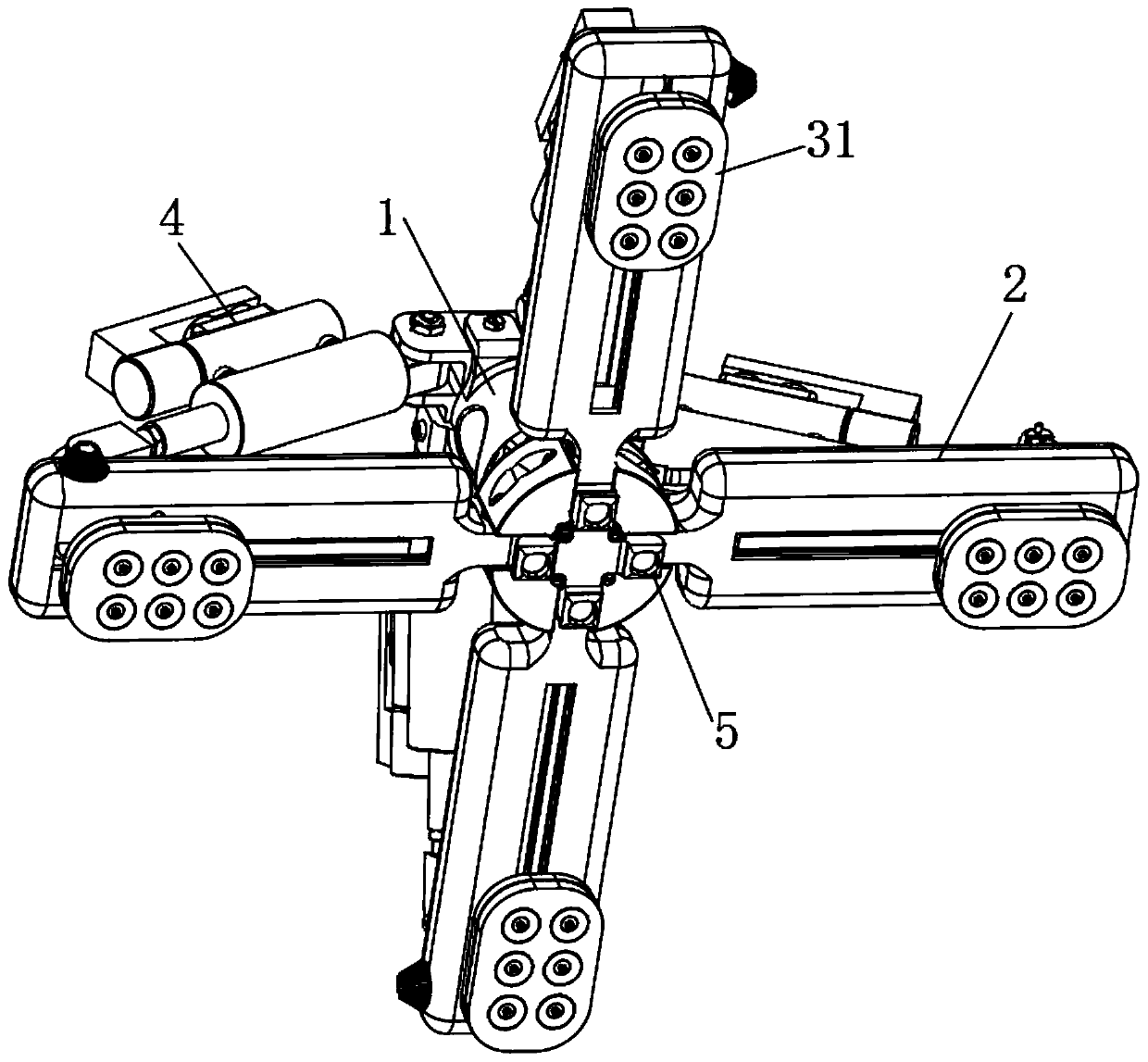

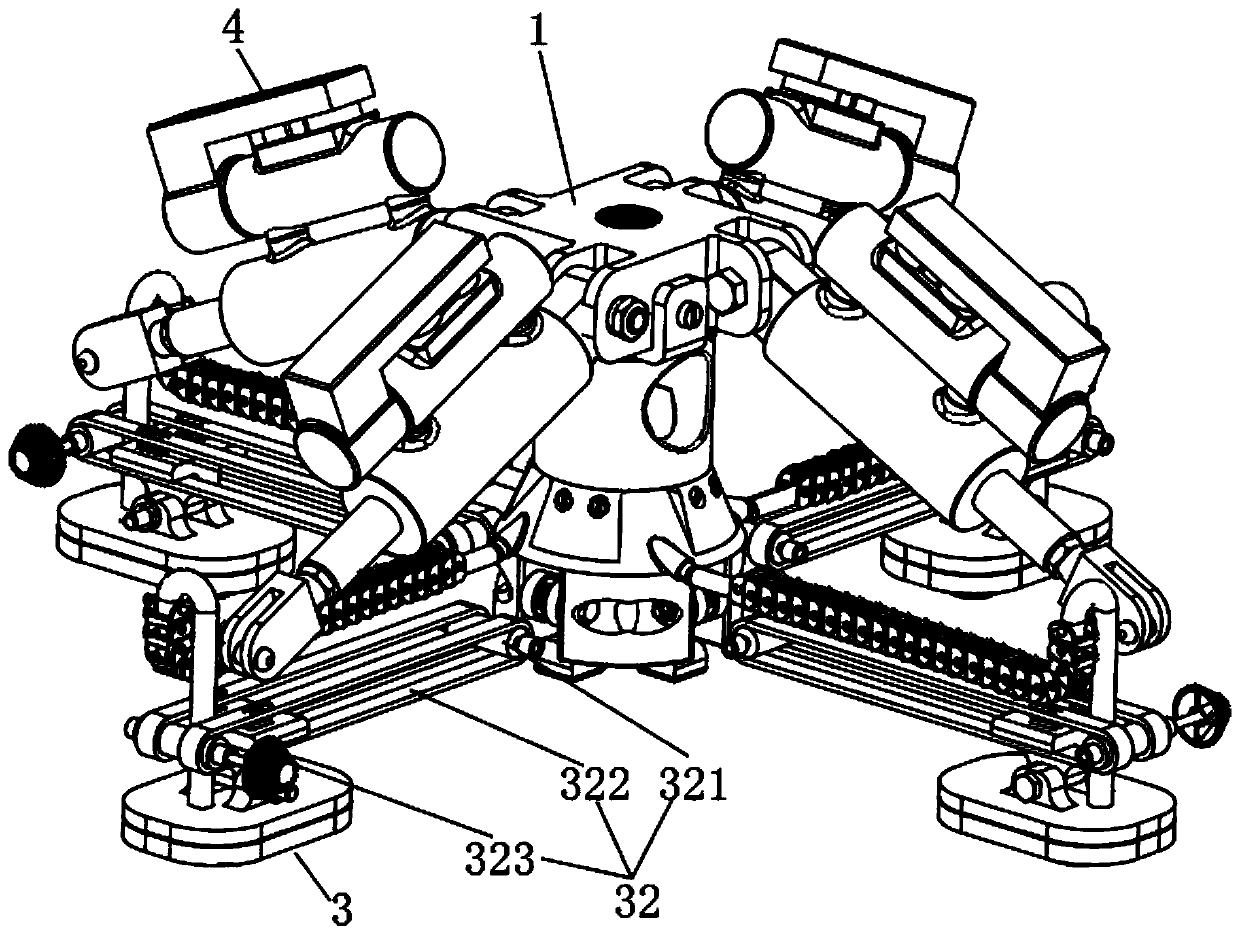

[0028] Example: such as Figures 1 to 3 As shown, the vacuum suction cup handling module of this embodiment includes a central base 1, at least two suction cup installation frames 2 and at least two groups of suction cup modules 3, and at least two of the above suction cup installation frames 2 are evenly and spacedly assembled on the above-mentioned center Around the substrate 1, the above-mentioned suction cup module 3 corresponds to the above-mentioned suction cup installation frame 2 one by one, and the above-mentioned suction cup module 3 includes a suction cup carrier 31, a mobile module 32 and a suction cup assembly installed on the lower end of the suction cup carrier 31, and the above-mentioned suction cup carrier 31 is set Below the corresponding suction cup mounting frame 2, the mobile module 32 is installed on the corresponding suction cup mounting frame 2, and is connected to the suction cup carrier 31 in transmission, so as to drive the suction cup carrier 31 to m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com