Film plating tool for eyeglasses

A lens and fixture technology, applied in optics, instruments, optical components, etc., can solve the problems of mirror edge reflection or heterochromia, affecting the quality of lens coating, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

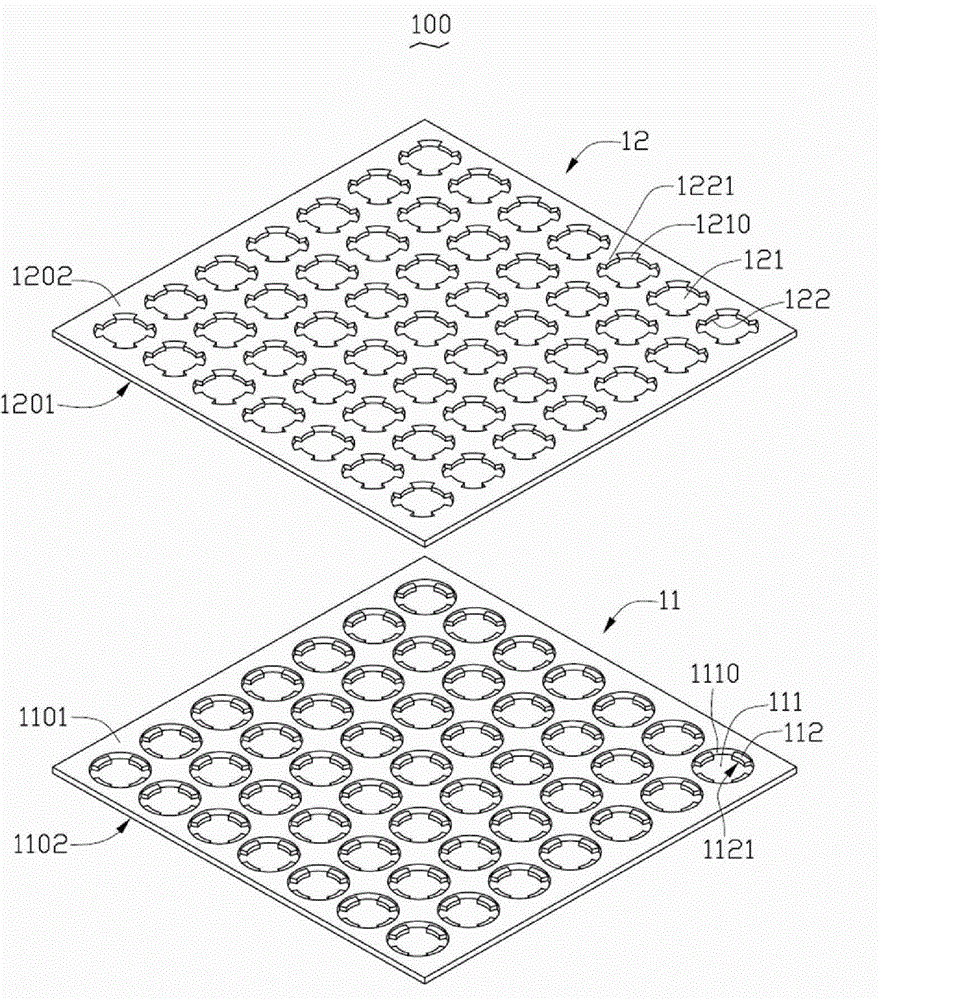

[0011] See figure 1 , the lens coating jig 100 provided by the embodiment of the present invention includes a base body 11 and a cover body 12 matched with the base body 11 .

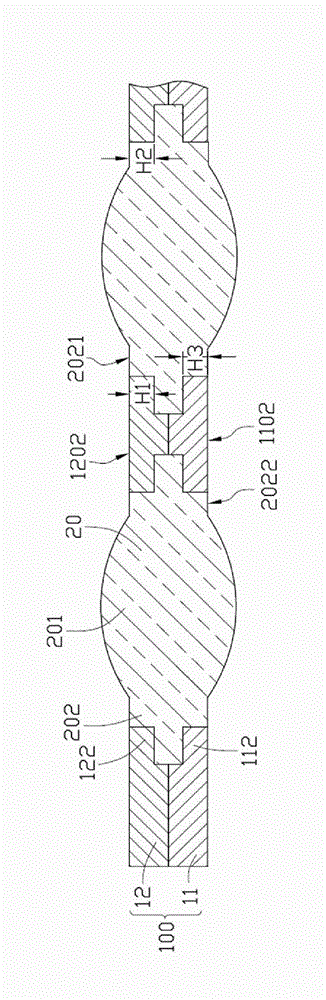

[0012] The substrate 11 has a first surface 1101 , a second surface 1102 opposite to the first surface 1101 , and a plurality of first through holes 111 passing through the first surface 1101 and the second surface 1102 . The inner wall 1110 of each first through hole 111 has a plurality of first protrusions 112 protruding toward the inner diameter thereof. In this embodiment, the plurality of first protrusions 112 are distributed symmetrically along the circumferential direction of the first through hole 111 , and the surface 1121 of the plurality of first protrusions 112 away from the first surface 1101 of the base 11 is in contact with The second surface 1102 of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com