Solar cell, solar cell burning glass and manufacturing method and embossing roller thereof

A technology of solar cells and concentrating glass, which is applied to glass manufacturing equipment, glass rolling, manufacturing tools, etc., can solve the problems of high production cost, difficulty in further increasing the ratio, and high production difficulty, so as to achieve low production cost and good quality. Light-gathering ability, easy to create effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The following describes the embodiments of the present invention in detail with reference to the drawings.

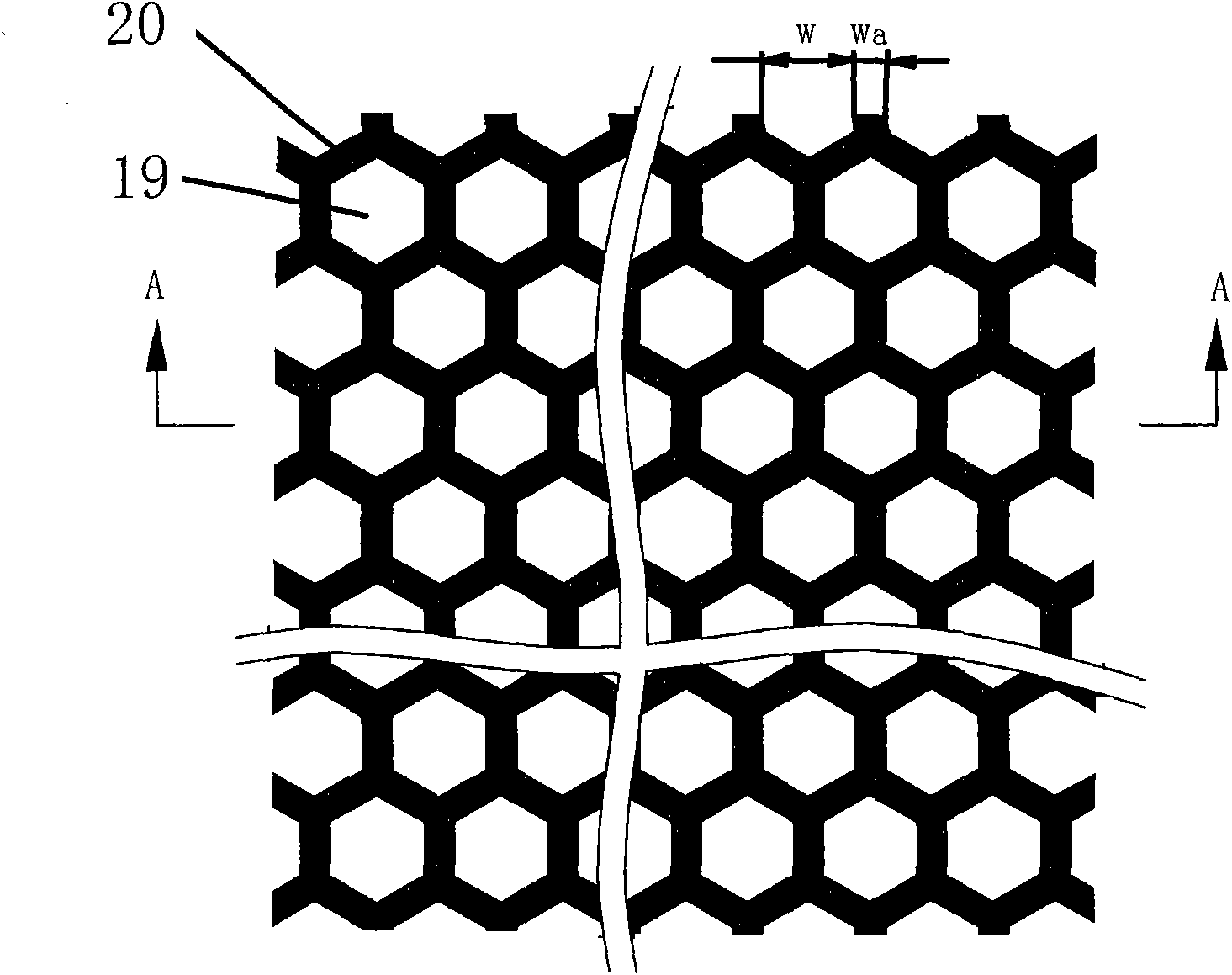

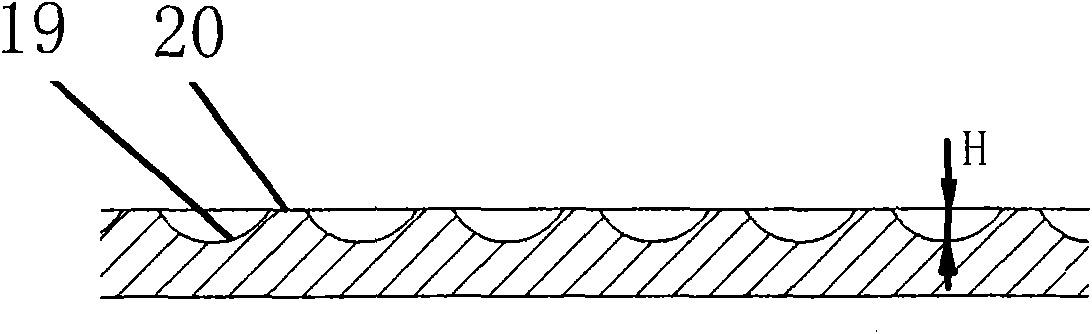

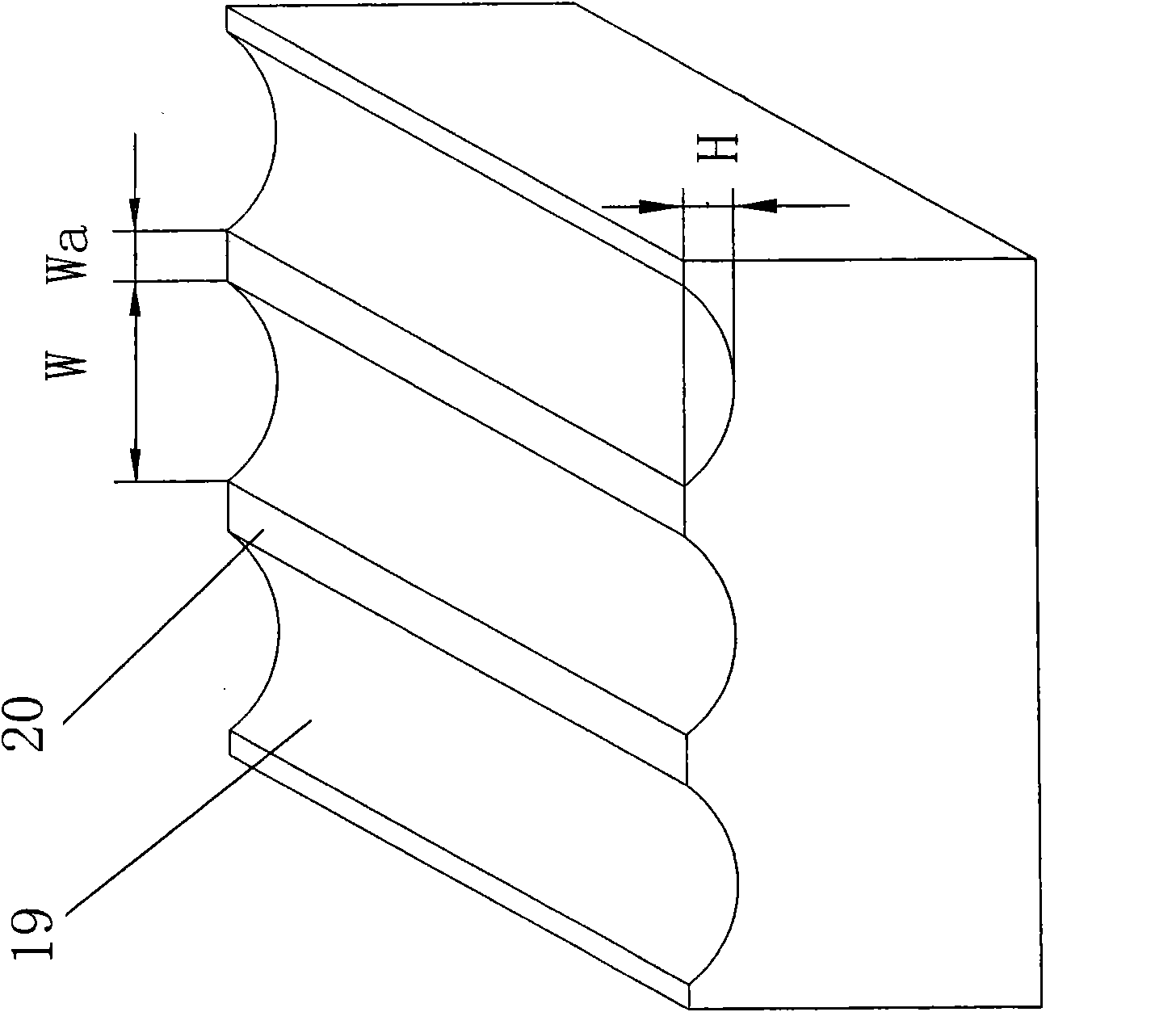

[0053] figure 2 , Figure 3a with Figure 3b These are the three-dimensional schematic diagram, the plan schematic diagram, and the B-B line cross-sectional view of the solar cell condensing glass in the embodiment of the present invention. The solar cell condensing glass 1 of the embodiment of the present invention is a kind of embossed ultra-white protective glass. As shown in the figure, the reflective condensing surface 19 and the non-condensing surface 20 form a stripe-shaped reflective condensing flower. W in the figure is reflective The width of the condensing surface 19, Wa is the width of the non-condensing surface 20, and H is the depth of the concave central portion of the reflective condensing surface 19. In this embodiment, the depth H is between 0.2 millimeters, W is 1.2 millimeters, and Wa is 0.25 millimeters. Therefore, the proportion of the reflect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com