Work machine

A technology of working machinery and pressurization mechanism, which is applied in the direction of manufacturing tools, metal processing, boring/drilling, etc., and can solve problems that cannot be ignored

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

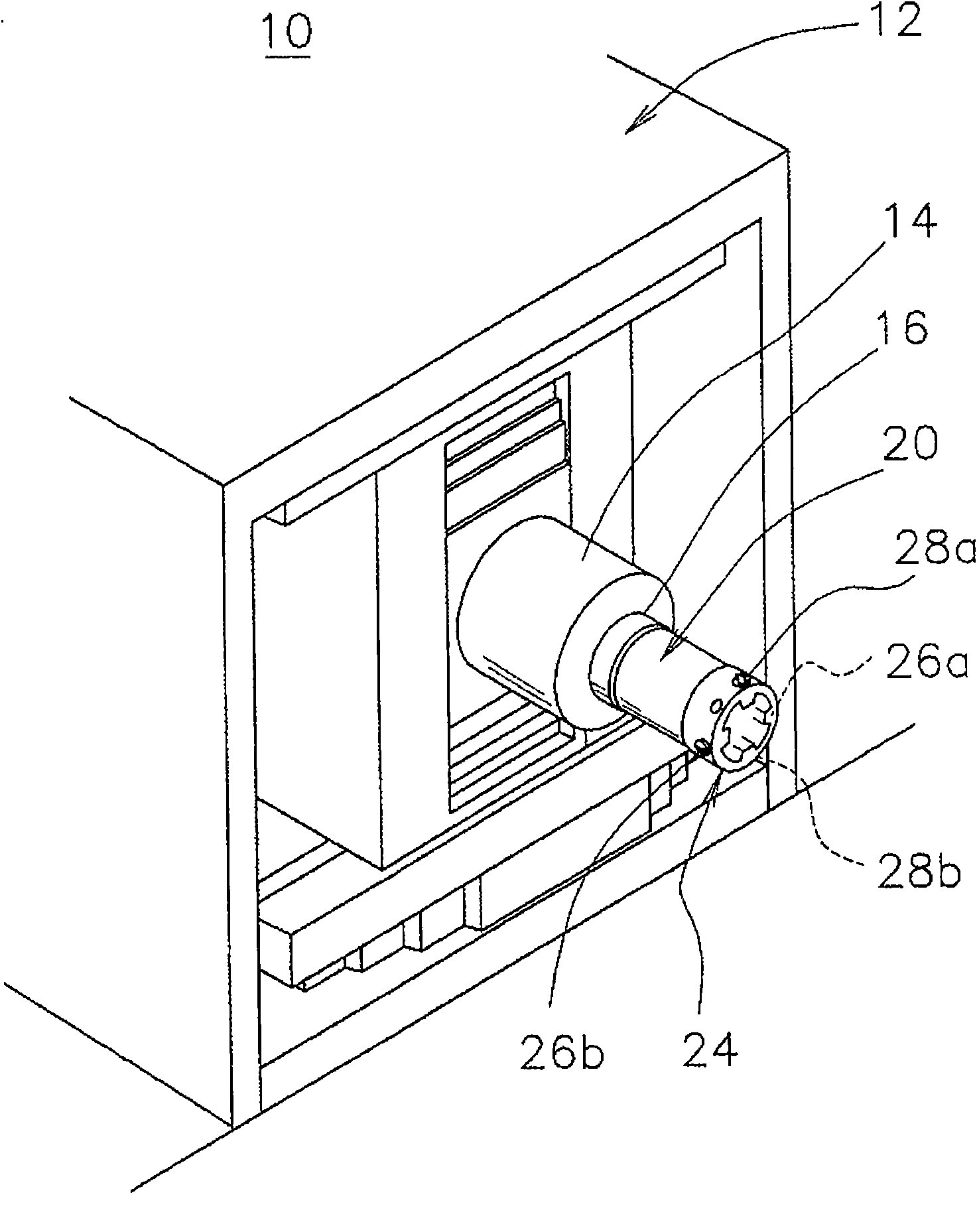

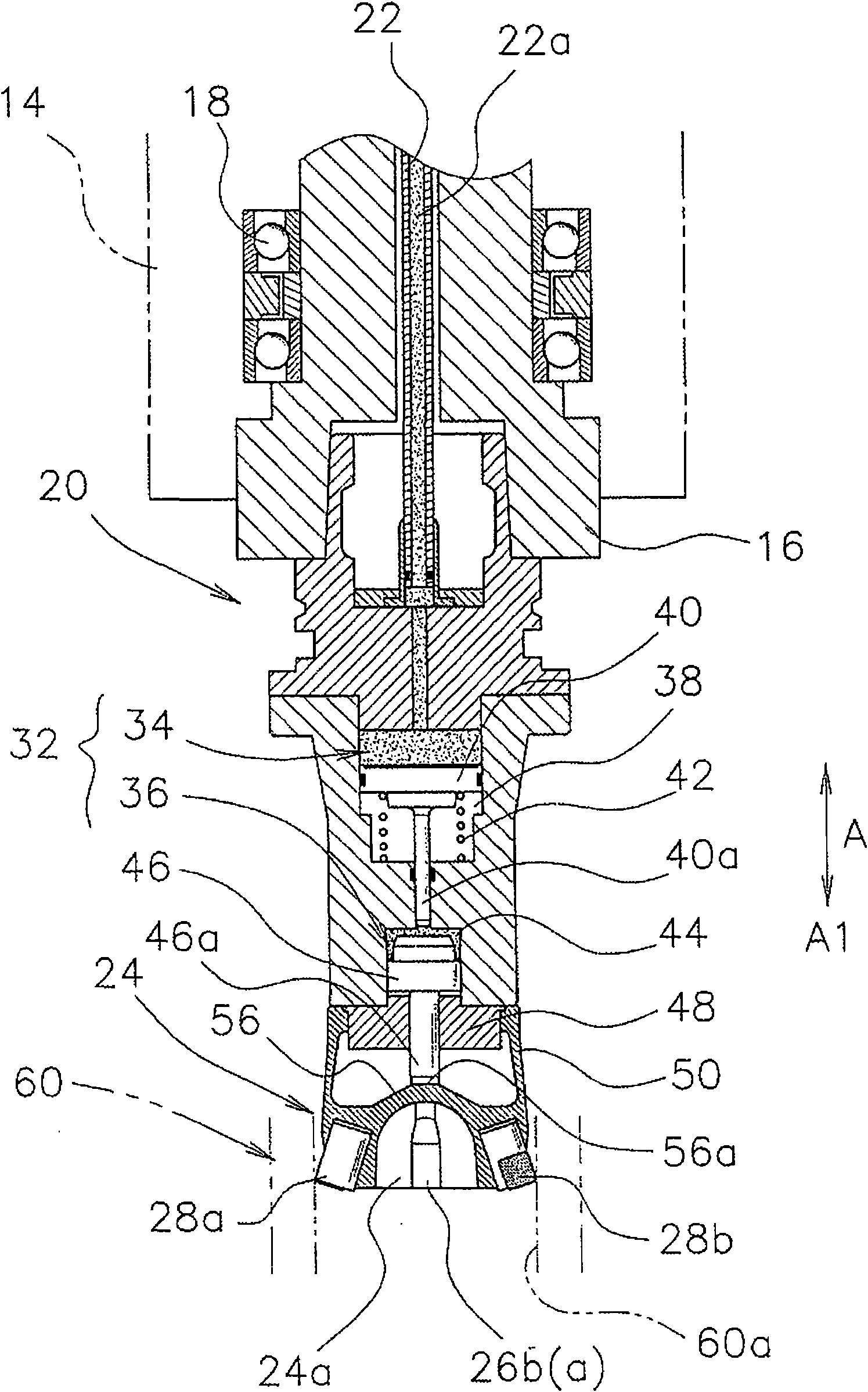

[0030] figure 1 It is a perspective explanatory view of a working machine 10 as a working machine according to the first embodiment of the present invention, figure 2 It is a cross-sectional explanatory view of the aforementioned machine tool 10 .

[0031] The machine tool 10 includes a main body portion 12 , and a housing 14 is slidably attached to the main body portion 12 . A main shaft (spindle) 16 is rotatably provided in the casing 14 via a bearing 18 , and a tool holder 20 is detachably attached to the main shaft 16 .

[0032] Such as figure 2 As shown, in the housing 14, a gas conduit 22 is arranged along the axis of the main shaft 16, and a gas passage 22a communicating with an unillustrated gas supply source is formed in the gas conduit 22.

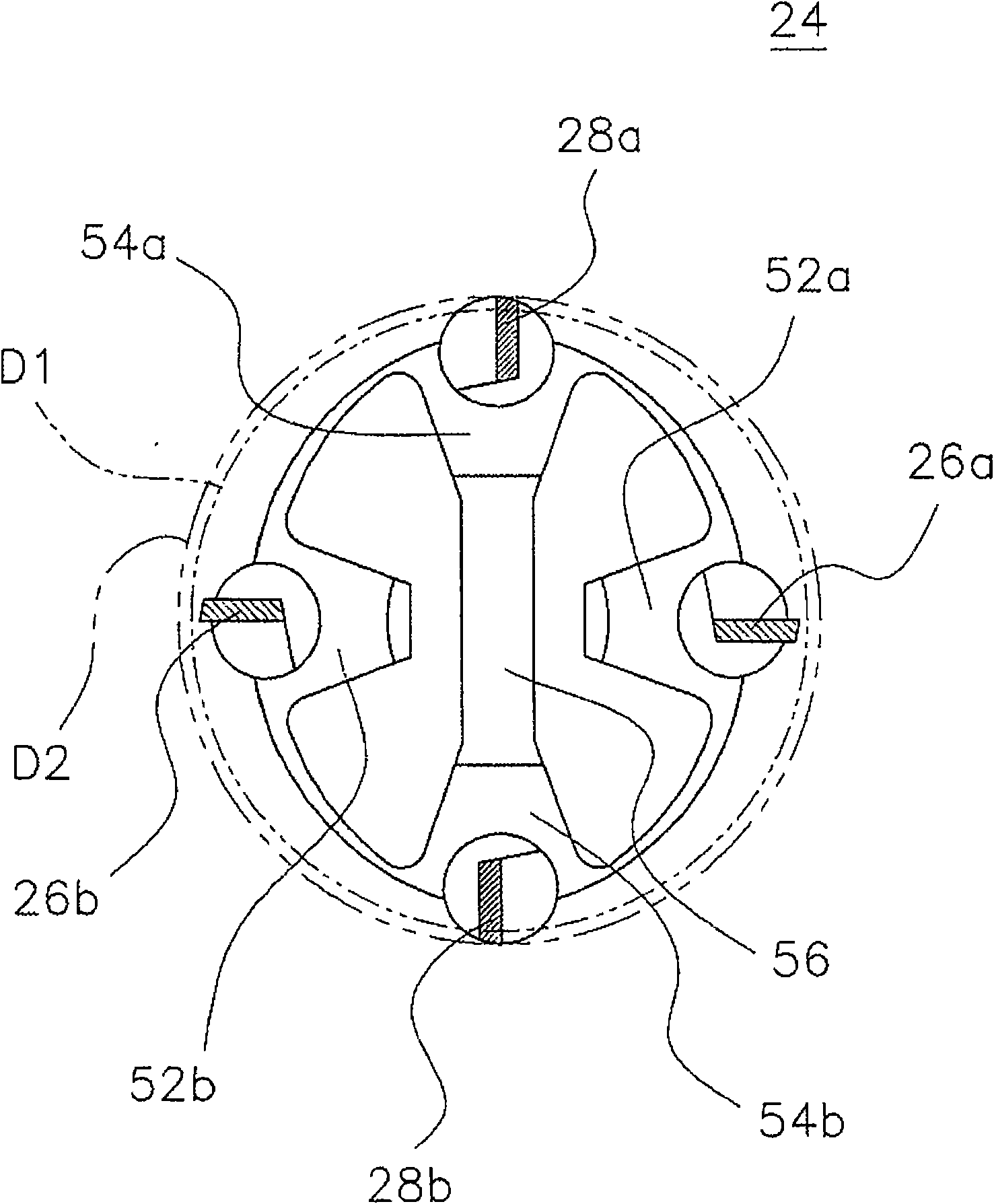

[0033] An annular elastic retainer portion 24 is mounted on the blade holder 20 . One end of the annular elastic holder portion 24 is fastened to the blade holder 20 and the other end forms an open end portion 24 a. Two or ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com