Method and machine for producing a paper web that is smooth on one side

A paper width, smoothing technology, applied in the paper machine, papermaking, textiles and papermaking, etc., can solve the problem of not setting the width guide, etc., to achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

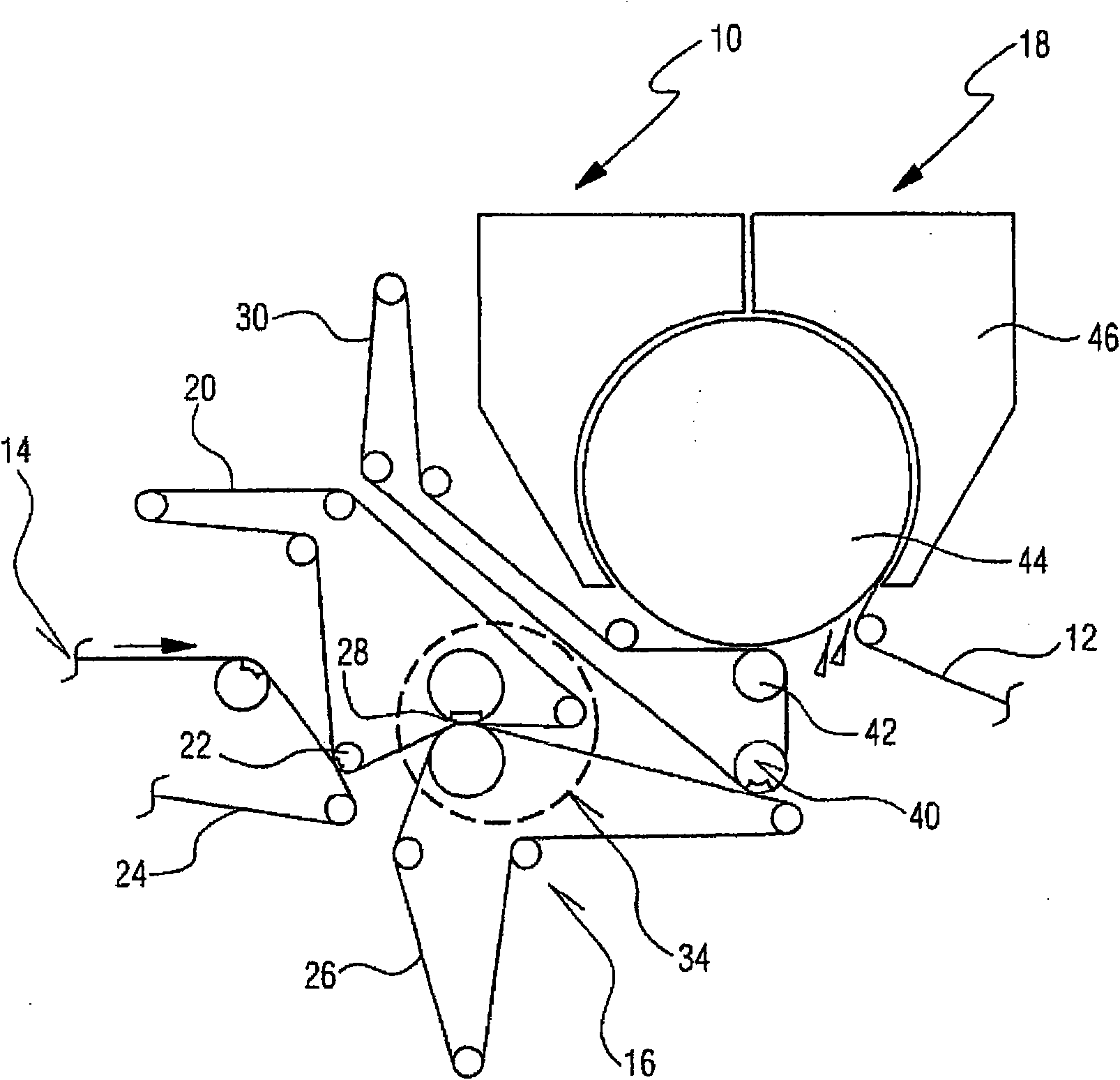

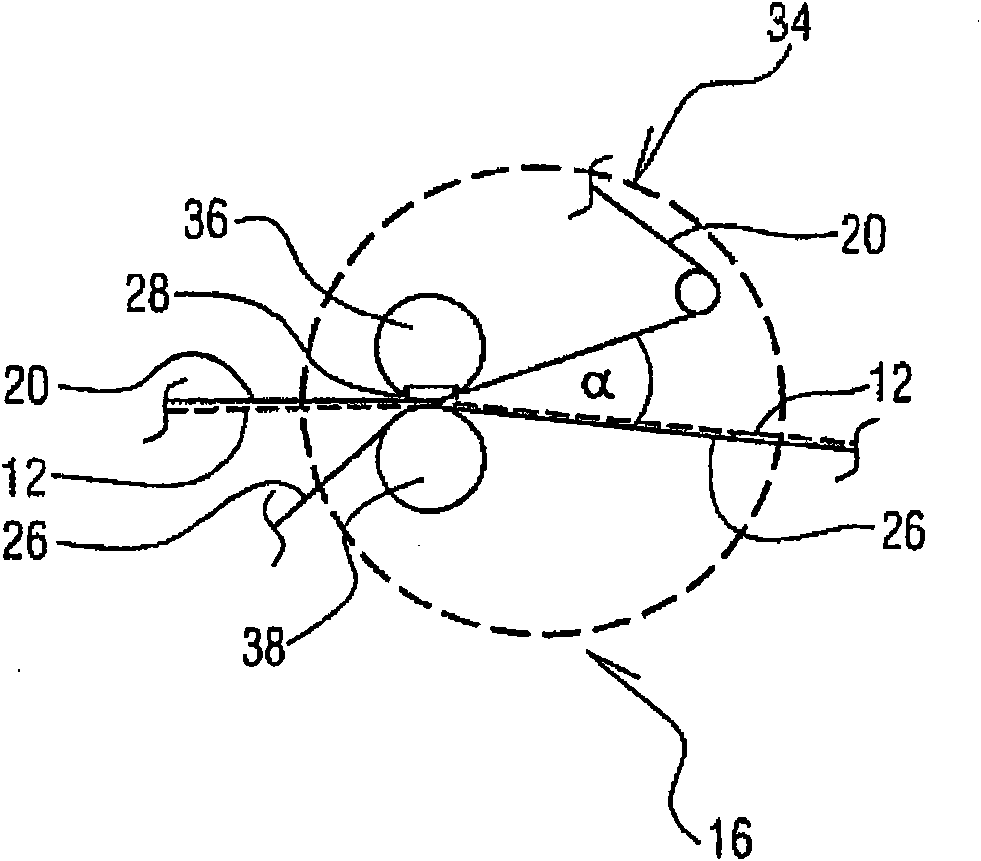

[0026] figure 1 An exemplary embodiment of a machine according to the invention for producing a one-sided smooth paper web with a forming zone 14 , a pressing zone 16 and a drying zone is shown in a schematic partial view 18.

[0027] In this case, the paper web 12 to be produced is received from the screen 24 by means of the water-absorbing first press felt 20 in the region of the first pick-up roll 22 wound by the press felt 20 and combined with the first press felt 20 The first press nip 28 assigned to the press zone 16 is guided together with a smooth conveyor belt 26 , which is at least substantially non-absorbent. The first press felt 20 is transferred away directly after the first press nip 28 from the paper web 12 and the smooth transfer belt 26 on which the paper web 12 exits the first press nip 28 .

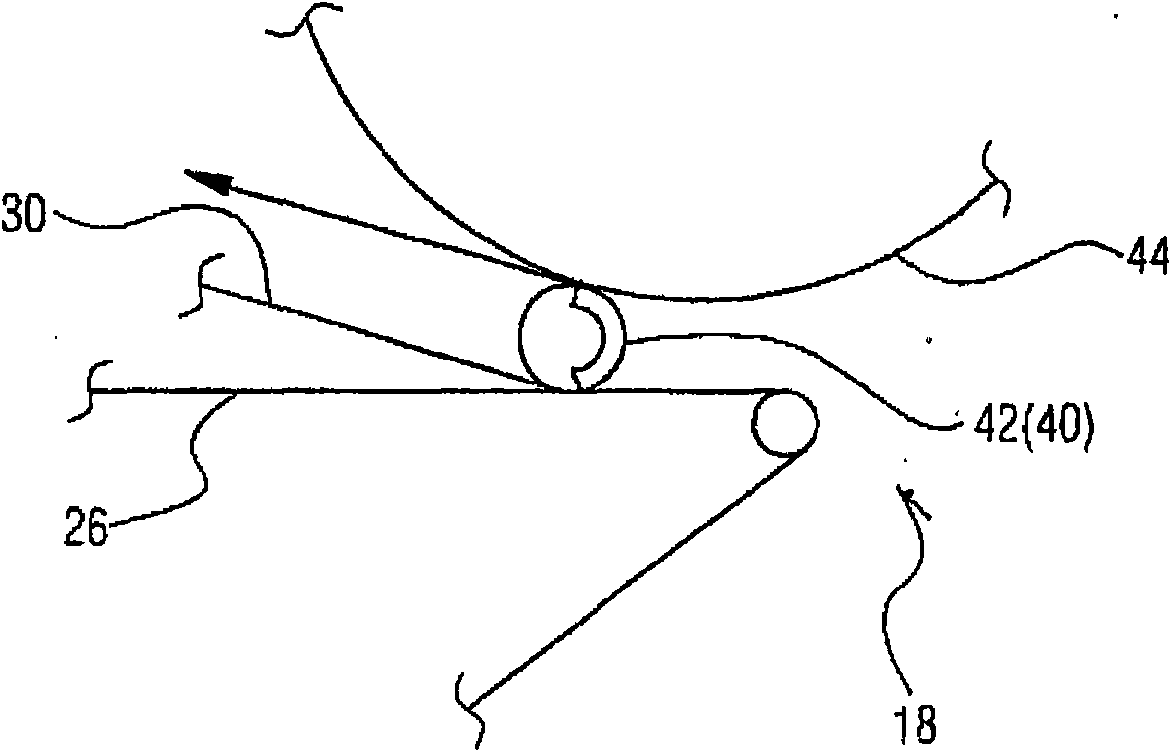

[0028] Next, the paper web 12 is received from the smoothing conveyor belt 26 by means of a second press felt 30 which is preferably moist and in particular unstructu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com