Preset flow control modules for dispensing valves

A technology of flow control and flow controller, applied in the direction of flow control, flow control without auxiliary power, non-electric variable control, etc., can solve the problems of inconsistent beverage quality, labor cost, damage to beverage integrity, waste of time and money, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

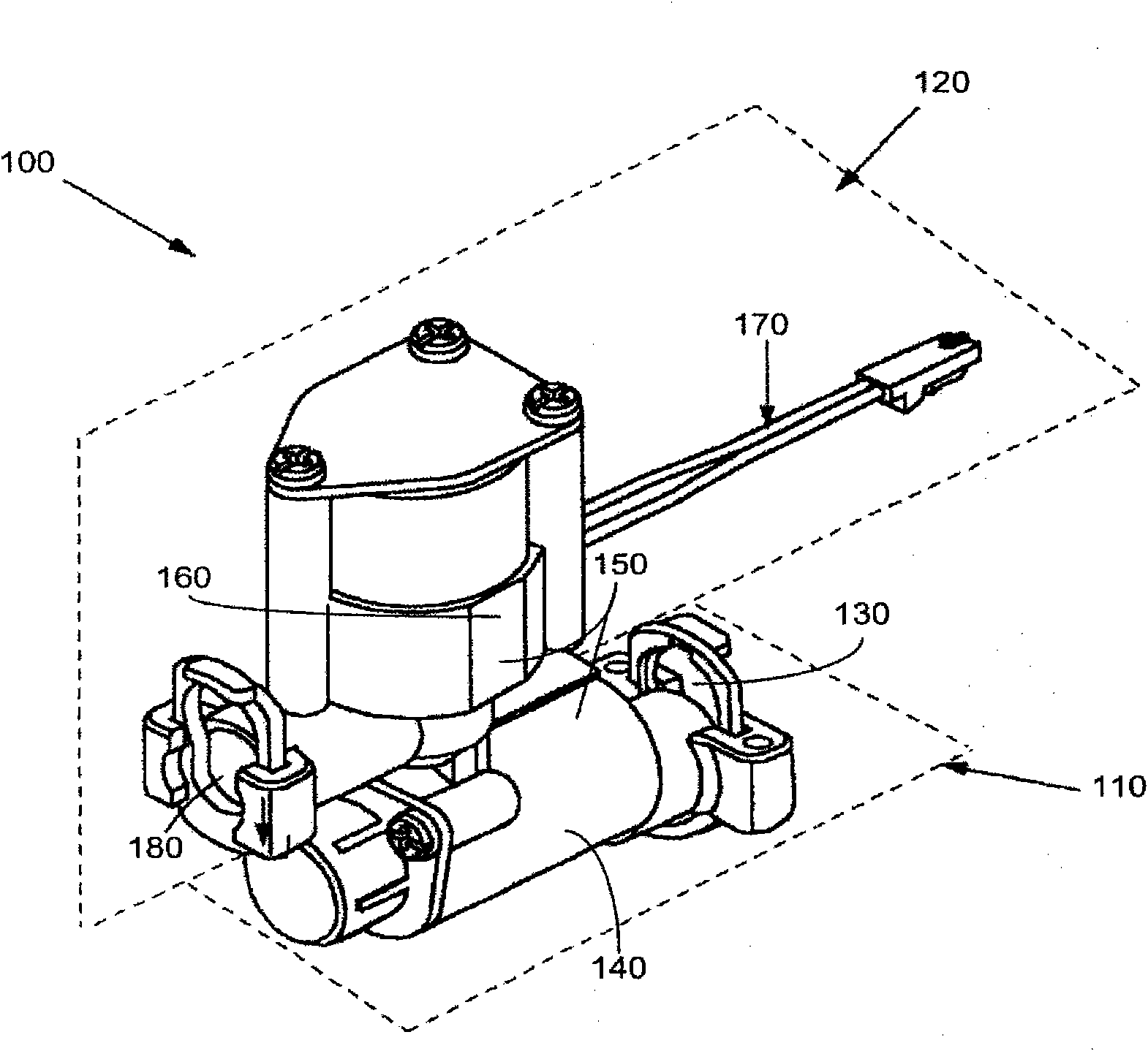

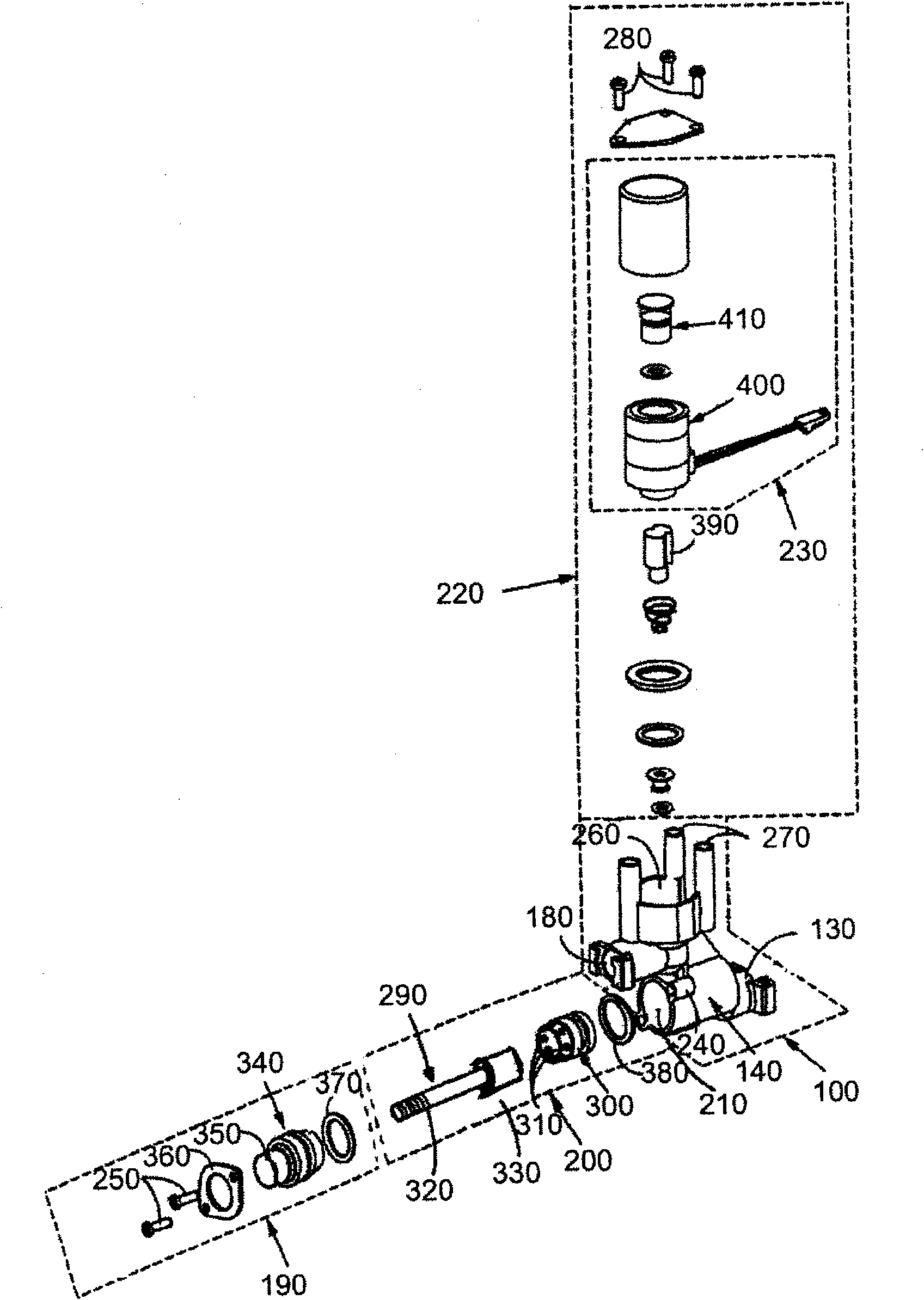

[0017] [117] Referring now to the drawings, in which like numerals represent like elements in the various figures, figure 2 The flow controller 100 described herein is shown. As noted above, the flow controller 100 is intended to be used with beverage dispenser valve assemblies (not shown) known in the art. As part of one of these beverage dispenser valve assemblies, the flow controller 100 can be connected to and be in fluid communication with one or more beverage fluid lines (not shown) such that the flow controller 100 receives beverage fluid from the beverage fluid lines, such as Post-mixed concentrates, post-mixed diluents, or pre-mixed beverage fluids. Flow controller 100 is operable to control the amount and flow rate of a flow of beverage fluid discharged by a dispensing nozzle (not shown) of a beverage dispenser valve assembly.

[0018] [118] If figure 2 As shown, flow controller 100 can be divided into two parts: flow control assembly 110 and valve assembly 120 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com