Inductor for inductor hardening of metal, rod-shaped toothed racks

An induction hardening and inductor technology, applied in the field of inductors, can solve the problems of time-consuming processing time and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

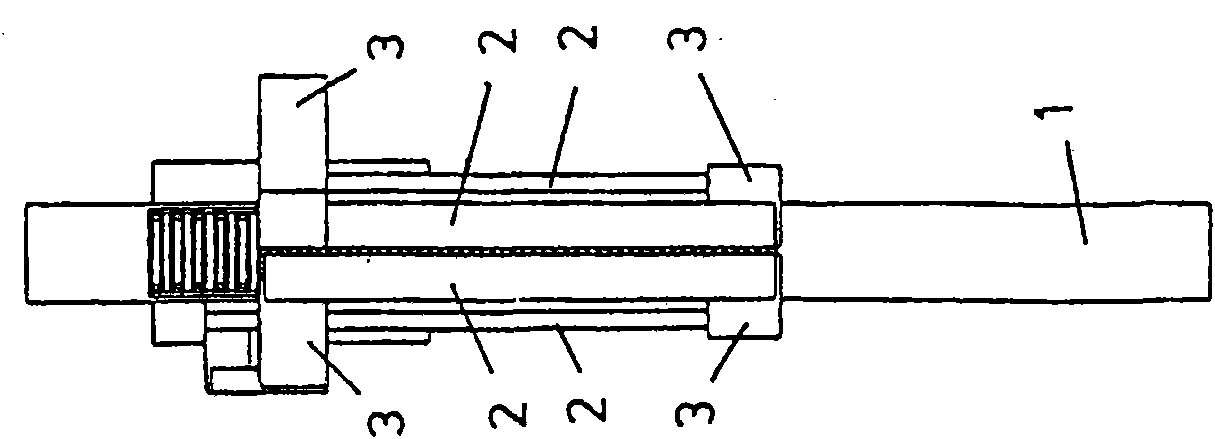

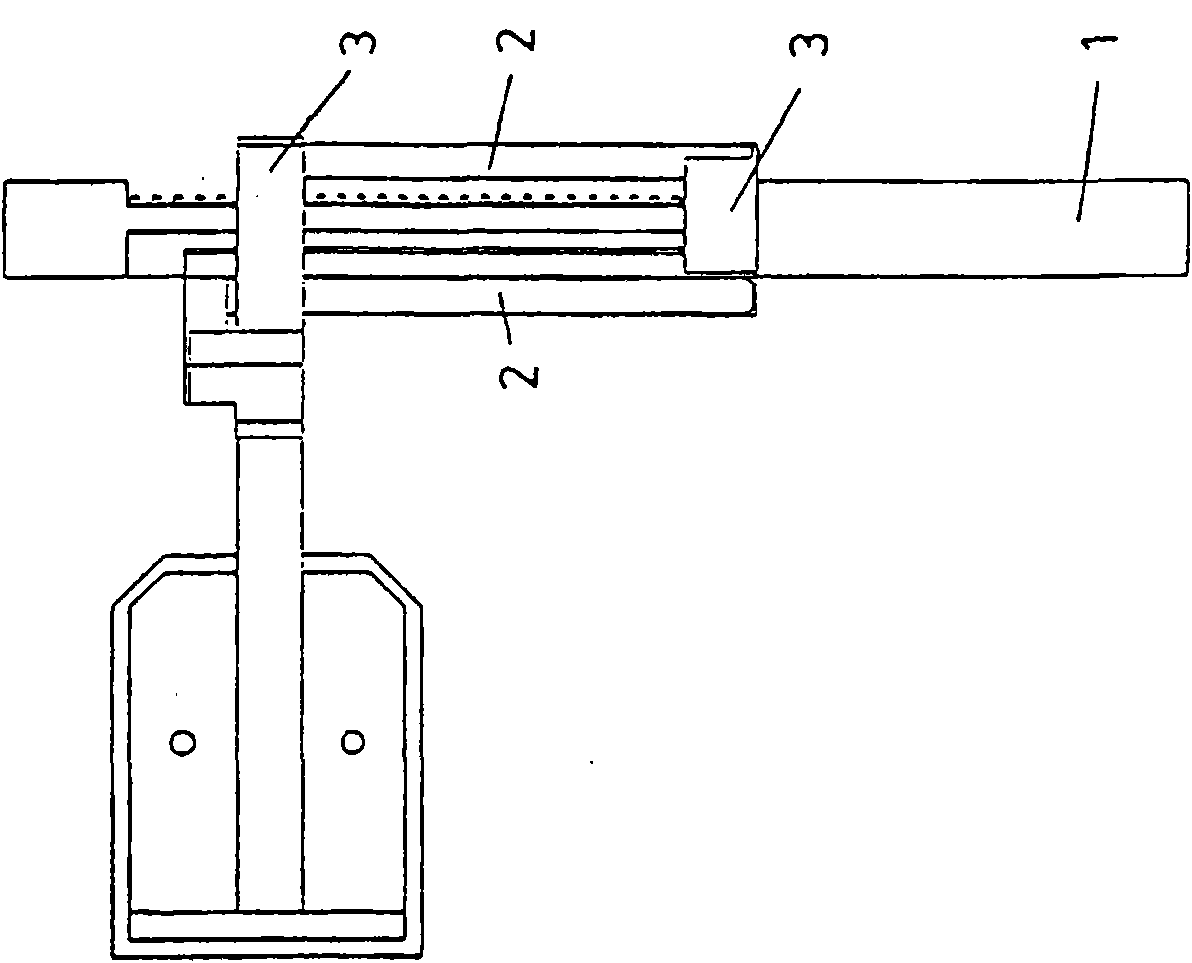

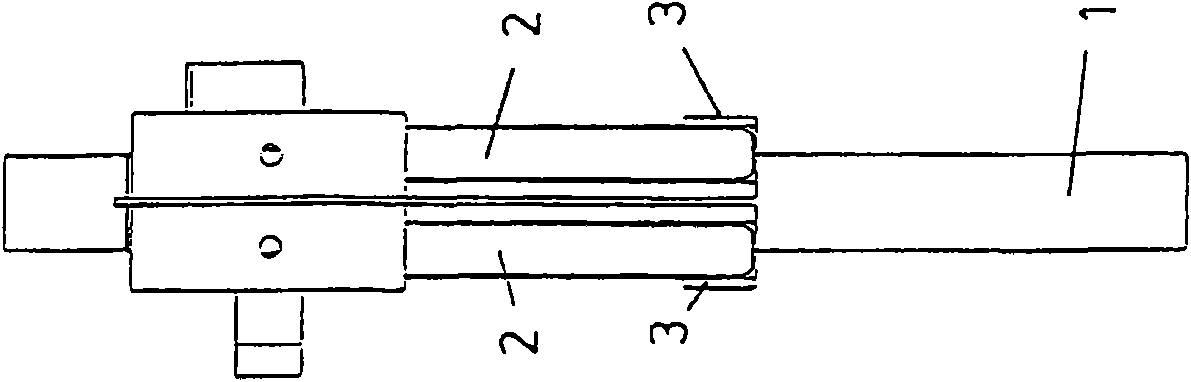

[0018] Figures 1 to 4 The embodiment in shows an inductor for hardening the toothed rack 1 . The inductor comprises a total of four elongated inductor elements 2 which extend parallel to the toothed rack 1 . In this case, the two sensor elements 2 are situated opposite the toothed side of the toothed rack 1 , while the two sensor elements 2 extend in the region of the rear side of the toothed rack 1 .

[0019] The mutually adjacent ends of the sensor elements 2 are connected to each other both mechanically and electrically by means of connecting elements 3 . This means that the inductor elements 2 are electrically connected in series with their connecting elements 3 , wherein the current flows along the inductor elements 2 after passing the respective connecting elements 3 back and forth as viewed in the longitudinal direction of the toothed rack 1 .

[0020] List of reference signs

[0021] 1 rack

[0022] 2 sensor element

[0023] 3 Connection elements

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com