High-efficiency corrosion-resistant multitubular condenser

A tube-and-tube condenser, corrosion-resistant technology, applied in steam/steam condensers, lighting and heating equipment, etc., can solve the problems of large losses, heavy weight, large condenser volume, etc., and achieve volume and weight reduction Small, good condensation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

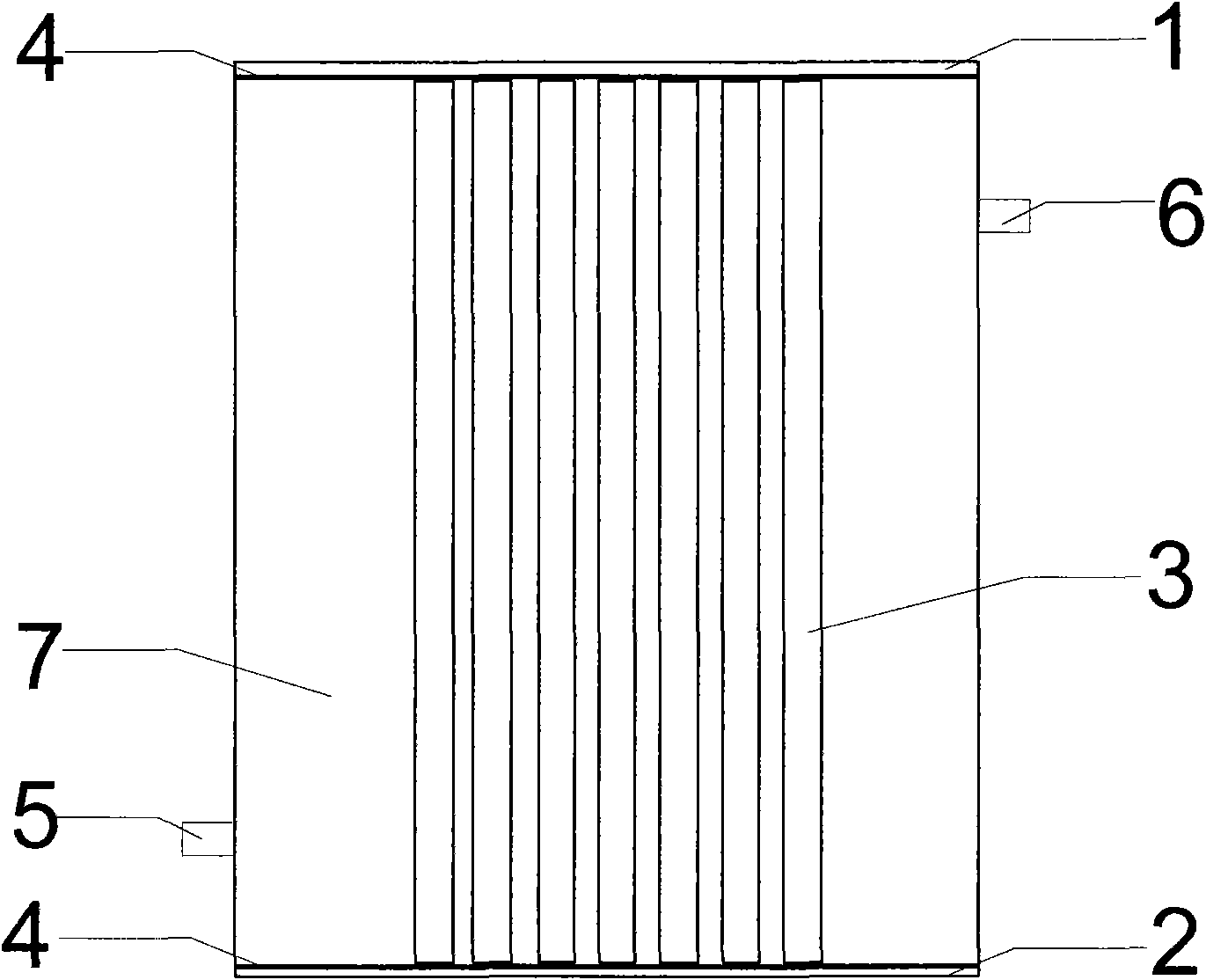

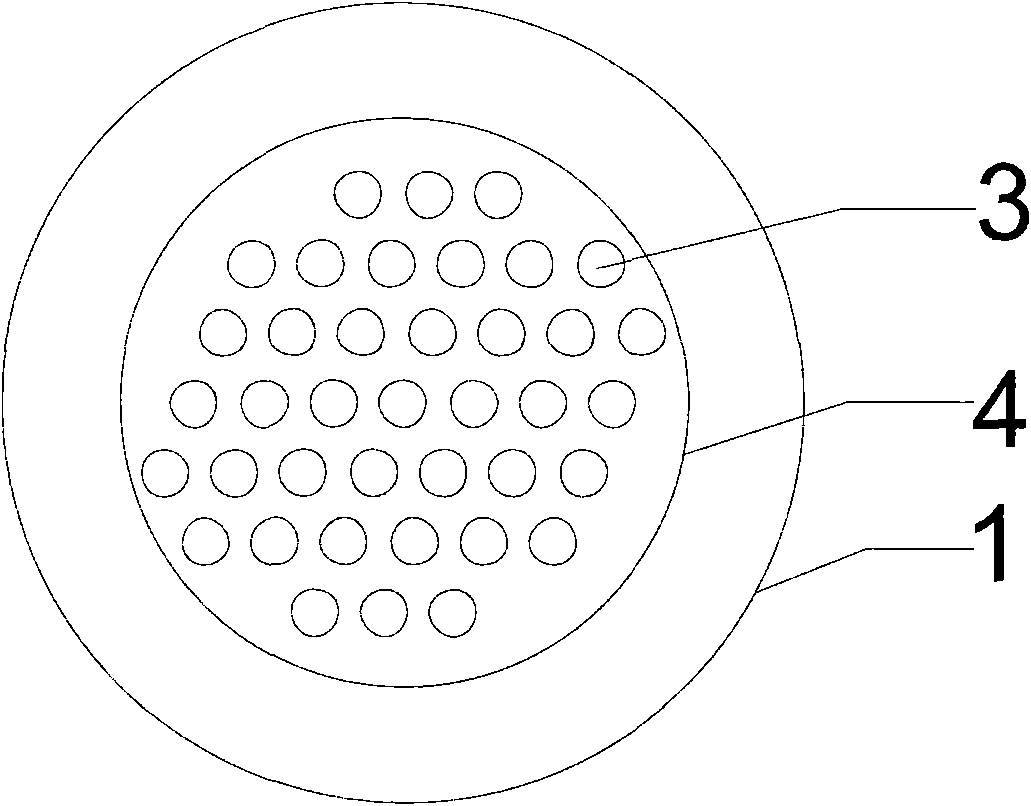

[0010] Such as figure 1 and 2 As shown, the high-efficiency corrosion-resistant shell-and-tube condenser of the present invention is a cylindrical shell, and the top and bottom of the shell 7 are fixed with a top cover 1 and a bottom cover 2 and communicated with the pipeline. A glass tube 3, the two ends of the glass tube 3 are fixed on the top cover 1 and the bottom cover 2, the top cover 1 and the bottom cover 2 are fixed with a rubber pad 4, and the rubber pad 4 is provided with a plurality of glass tubes. A hole corresponding to the pipe 3; a water inlet 5 is opened at the lower part of the side of the cylinder body 7, and a water outlet 6 is opened at the upper part of the side opposite to the water inlet 5. In this way, the chemical gas enters the glass tube 3 through the pipeline to condense, and then flows out from the other end of the glass tube 3. The condensed water enters from the lower water inlet 5 on the side of the condenser cylinder 7, and flows out from the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com