Rolling of a strip in a rolling train using the last stand of the rolling train as a tension reducer

A rack and strip technology, applied in tension/pressure control, driving devices for metal rolling mills, metal rolling, etc., can solve difficult and unrealizable problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

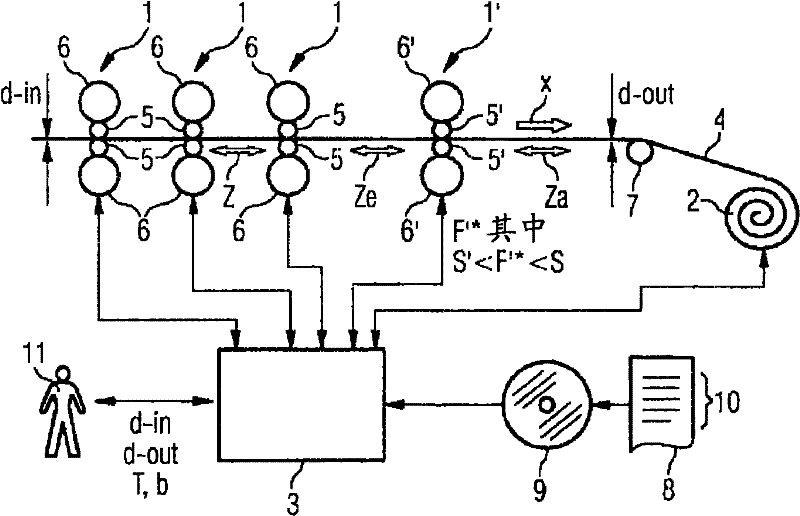

[0044] according to figure 1 , the rolling mill train according to the invention has a plurality of main rolling mill stands 1, 1' as well as a coiler 2 and a control device 3. The strip 4 passes successively through the main rolling stands 1, 1' and is then coiled up by a coiler 2. The control device 3 controls the main rolling mill stands 1, 1' and the coiler.

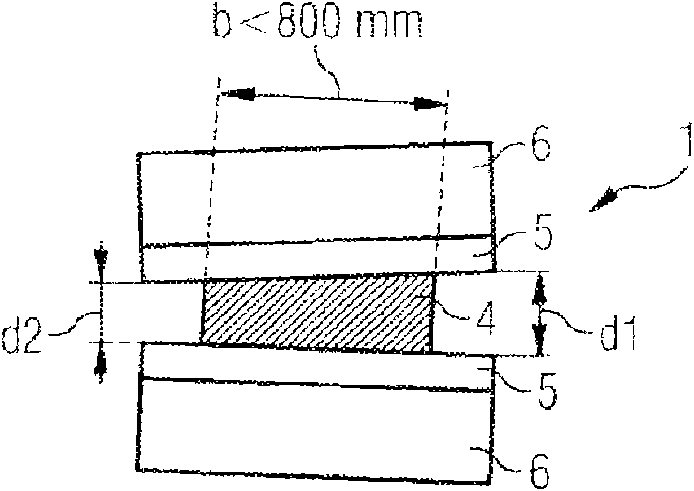

[0045] The number of main rolling mill stands 1, 1' is generally four to seven. It is a minimum of two. Main rolling mill stands 1, 1' in general (see also figure 1 ) is a four-roller frame. That is, it has work rolls 5, 5' and backup rolls 6, 6', respectively. It can optionally have additional additional rollers, for example intermediate rollers in the case of a six-roll stand.

[0046] The coiler 2 is arranged directly after the last main rolling stand 1'. The term "directly behind" means in this case that there are no components affecting the tension Z occurring in the strip 4 to a significant extent b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com