Gas and water atomizing nozzle

A water atomization and nozzle technology, which can be applied to spray devices, liquid spray devices, etc., can solve the problems of nozzle blockage, high cost, affecting the use effect, etc., and achieve the effect of firm welding and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

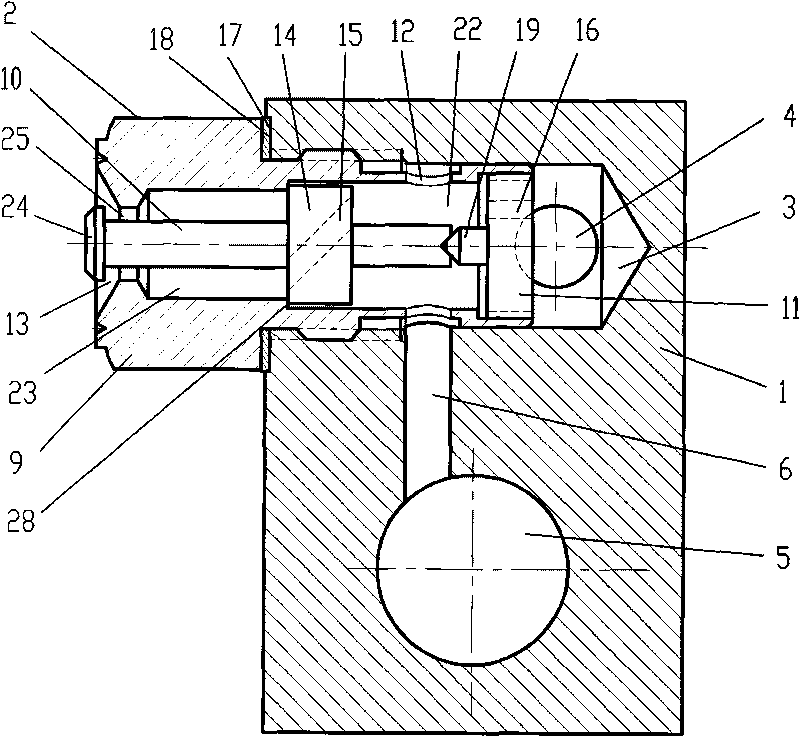

[0018] The specific embodiment of the present invention is described in detail below in conjunction with accompanying drawing:

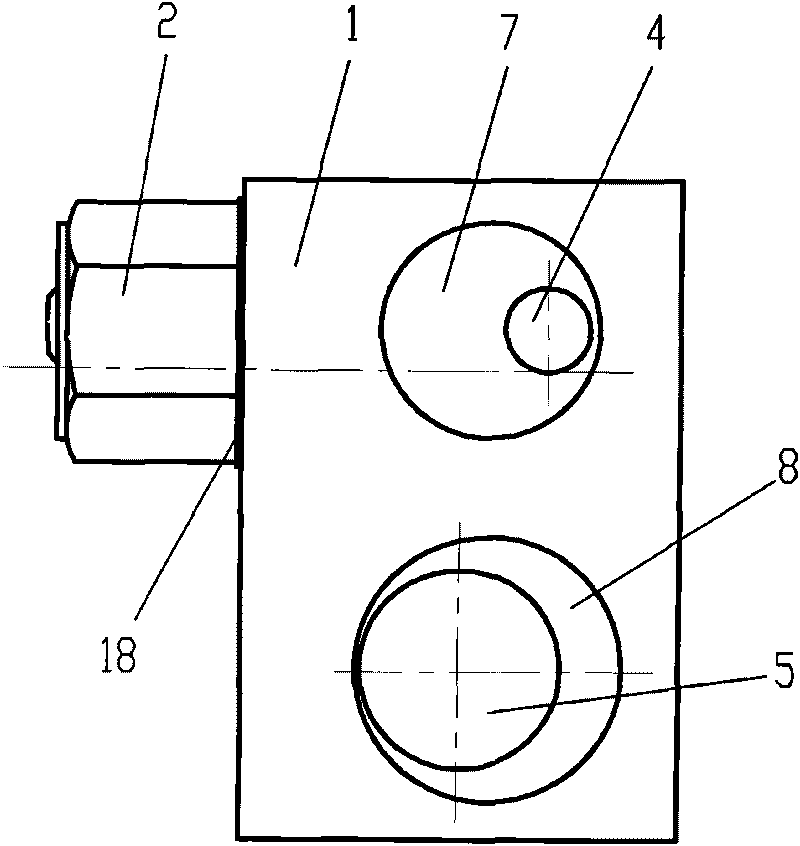

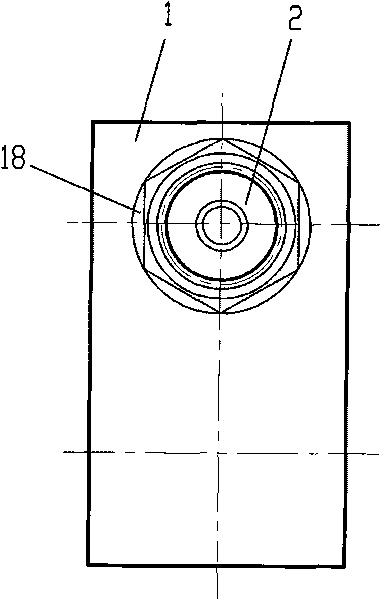

[0019] Such as figure 1 , figure 2 with image 3 As shown, the gas and water atomizing nozzle of the present invention includes a valve body 1 and a spray nozzle 2, a screw hole 3 is provided on the valve body 1, a sealing groove 17 is arranged at the opening of the screw hole 3, and a sealing groove 17 is installed in the sealing groove 17. Gasket 18 is arranged. The screw hole 3 is screwed with a nozzle 2, and the rear end of the screw hole 3 is provided with a first through hole 4 communicating with the screw hole 3 for installing a water inlet pipe. The bottom of the screw hole 3 is provided with a second through hole 5 for For the installation of the air intake pipe, there are first weld seams 7 and second weld seams 8 at the openings at both ends of the first through hole 4 and the second through hole 5 respectively. The nozzle 2 includes a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com