Safety single-punch controller for punch

A safety sheet and controller technology, applied in engineering safety devices, maintenance and safety accessories, manufacturing tools, etc., can solve problems such as reset instability, failure to return to original position, damage to molds or punches, etc., to improve safety performance, Reasonable structure design, with reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

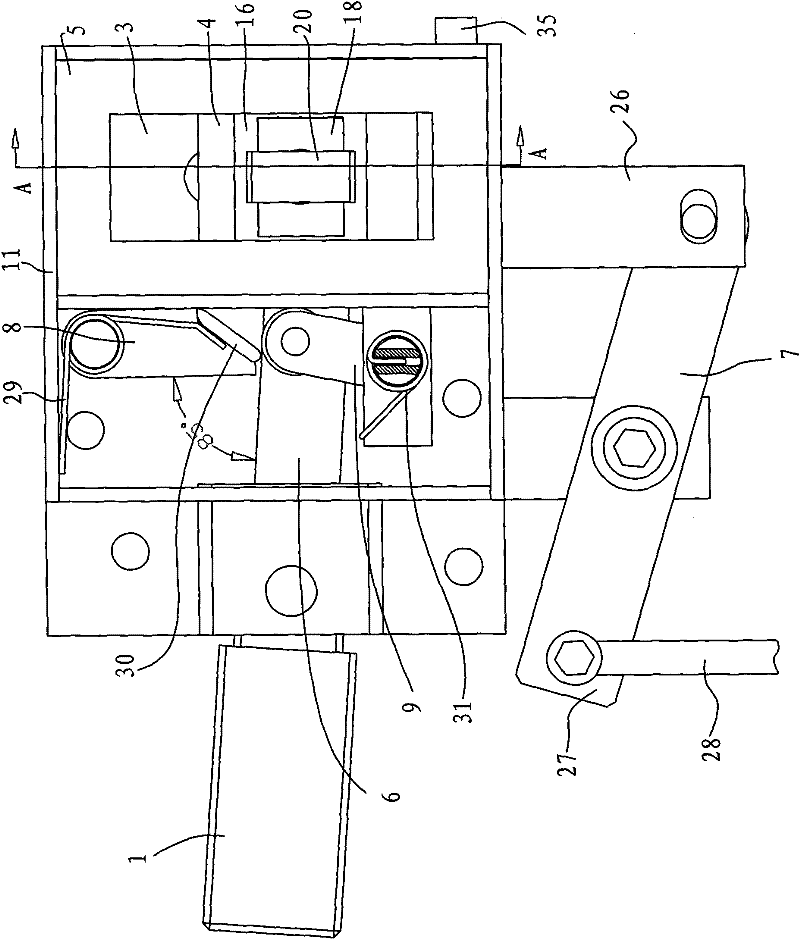

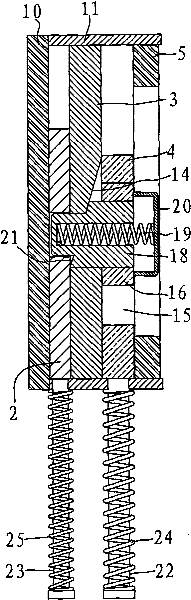

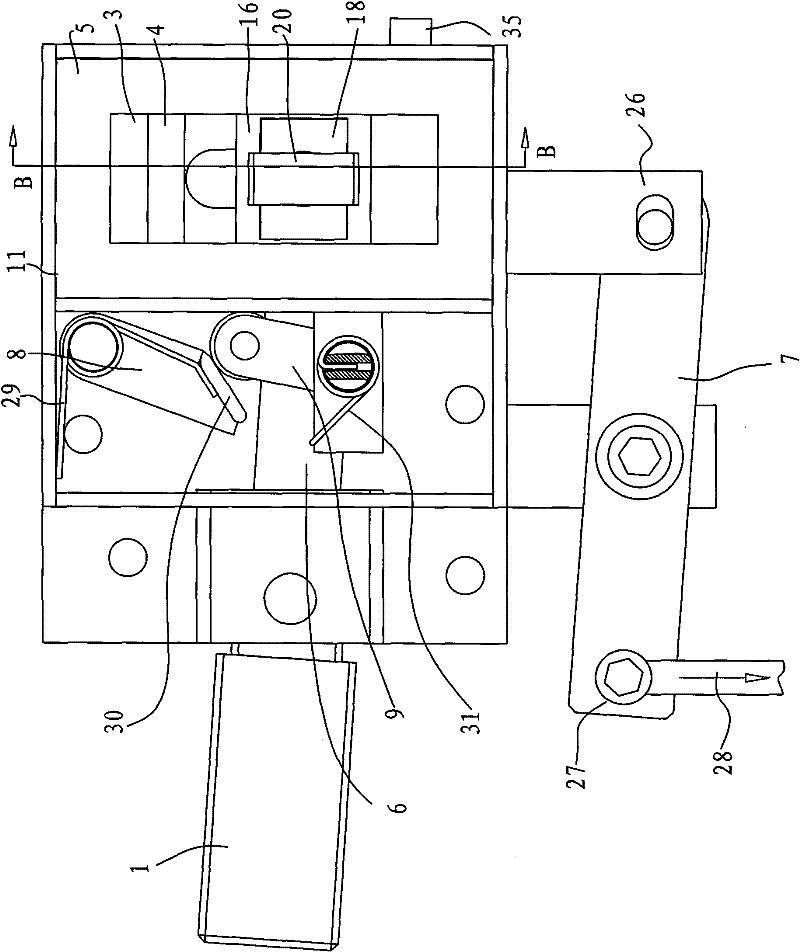

[0039] A safety single-punch controller for a punching machine, comprising a buffer head 1, a housing, a hook plate 2, a middle plate 3, a slide plate 4, a pressure plate 5, a swing rod 6, a lever 7, and a lock block arranged in sequence in the housing 8 and lock wheel 9. The housing includes a back plate 10, a main body 11 and a panel 12, and the back plate 10 and the panel 12 are respectively welded on the front and rear sides of the main body 11 (see Figure 14 ).

[0040] The swing rod 6 is installed on the back plate 10 through the pivot movement, wherein the outer end of the swing rod 6 protrudes from the side of the main body 11, the buffer head 1 is installed on the outer end of the swing rod 6, and the buffer head 1 and the swing rod 6 are buffered The spring is connected, and the inner end of the swing rod 6 extends into the housin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com