Chlorine-and-silicon-contained waste liquid and gas pollution-free treating method and recycling system thereof

A treatment method and technology for waste liquid, applied in combustion methods, separation methods, chemical instruments and methods, etc., can solve the problems of clogging of waste heat recovery devices, influence of process equipment operation, clogging of waste heat recovery devices, etc. The effect of avoiding ash clogging in the heat exchange area and improving the heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

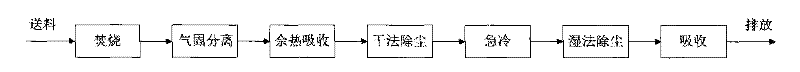

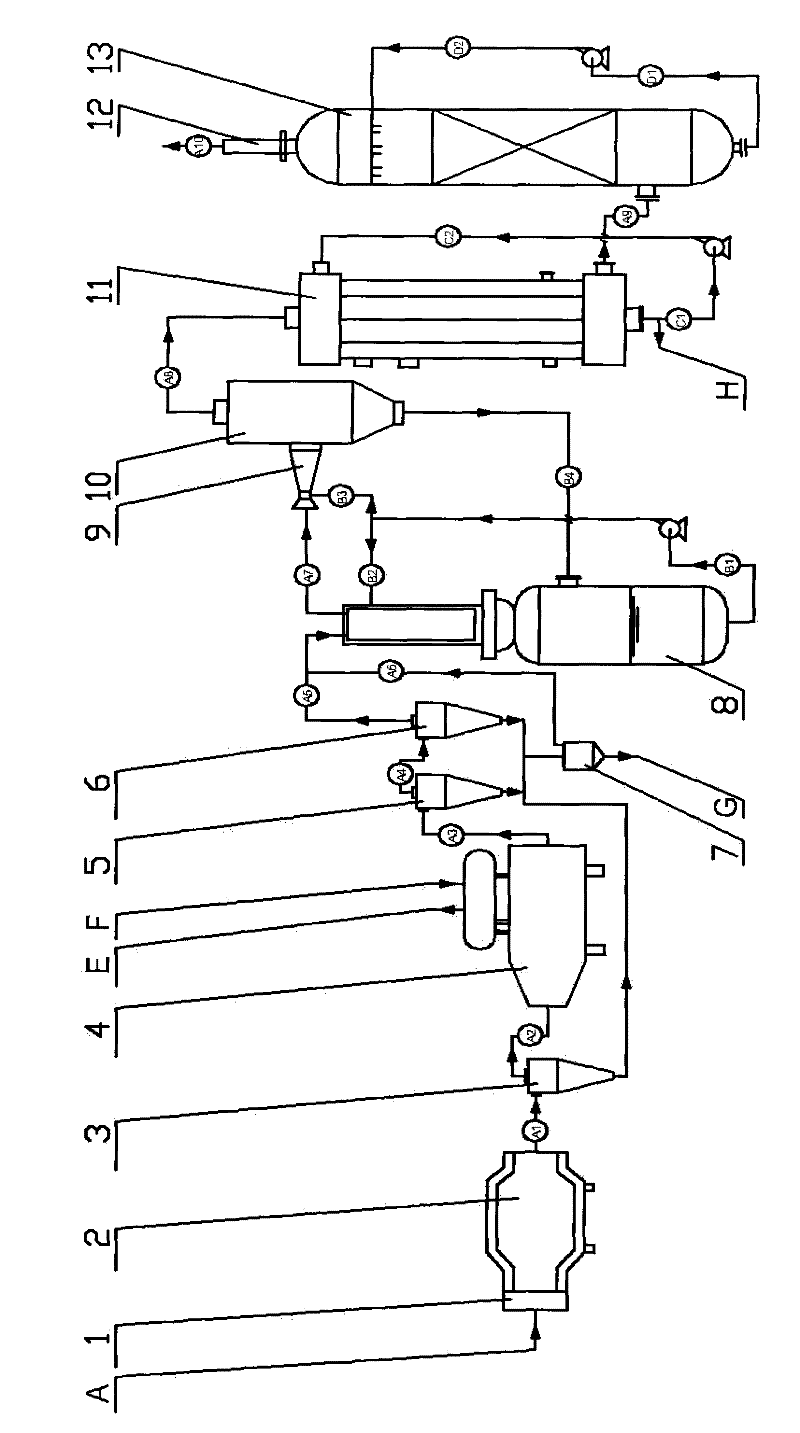

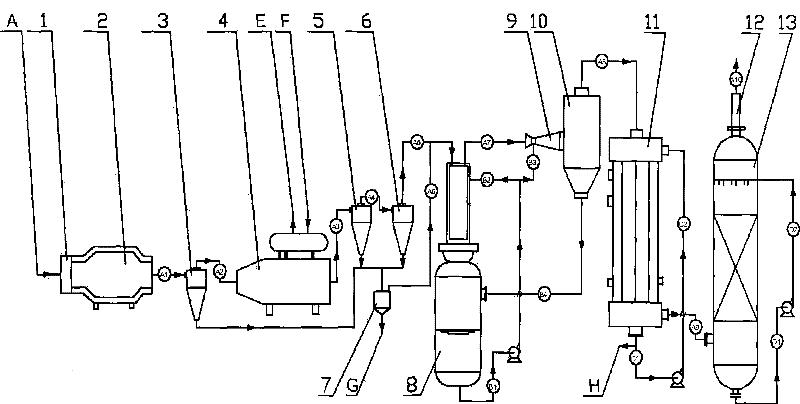

[0036] Such as figure 1 Described, a kind of chlorine-containing silicon-containing waste liquid, waste gas pollution-free treatment method, it comprises the following steps:

[0037] (1) Incineration: Pass the waste liquid and waste gas into the burner and incinerator for incineration, and the incineration temperature is 800°C;

[0038] (2) Gas-solid separation: The chlorine-containing silicon-containing flue gas produced in step (1) is passed into the high-temperature separator. The high-temperature separator has the technical characteristics of high temperature resistance, corrosion resistance, and wear resistance, and has various specifications and models. For example, using a cyclone separator structure with a water cooling device, the working temperature is below 1400 ° C, so that more than 50% of SiO with a diameter greater than 10 microns in the high-temperature flue gas 2 Wait for the solid particles to separate out;

[0039] (3) waste heat absorption: the flue gas ...

Embodiment 2

[0066] Such as figure 1 Described, a kind of chlorine-containing silicon-containing waste liquid, waste gas pollution-free treatment method, it comprises the following steps:

[0067] (1) Incineration: Pass the waste liquid and waste gas into the burner and incinerator for incineration, and the incineration temperature is 1400°C;

[0068] (2) Gas-solid separation: The chlorine-containing silicon-containing flue gas produced in step (1) is passed into the high-temperature separator. The high-temperature separator has the technical characteristics of high temperature resistance, corrosion resistance, and wear resistance, and has various specifications and models. For example, using a cyclone separator structure with a steam cooling device, the working temperature is below 1400 ° C, so that more than 50% of the SiO in the high-temperature flue gas has a diameter greater than 10 microns 2 Wait for the solid particles to separate out;

[0069] (3) waste heat absorption: the flue ...

Embodiment 3

[0076] Such as figure 1 Described, a kind of chlorine-containing silicon-containing waste liquid, waste gas pollution-free treatment method, it comprises the following steps:

[0077] (1) Incineration: Pass the waste liquid and waste gas into the burner and incinerator for incineration, and the incineration temperature is 1200°C;

[0078] (2) Gas-solid separation: The chlorine-containing and silicon-containing flue gas produced in step (1) is passed into the high-temperature separator. The high-temperature separator has the technical characteristics of high temperature resistance, corrosion resistance, and wear resistance, and has various specifications and models. For example, using a cyclone separator structure with water cooling or steam cooling device, the working temperature is below 1400 ° C, so that more than 50% of the SiO in the high-temperature flue gas has a diameter greater than 10 microns 2 Wait for the solid particles to separate out;

[0079] (3) waste heat ab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| separation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com