Cone of thin speaker

A loudspeaker and sound cone technology, which is applied in the field of acoustics and electricity, can solve the problems of unfavorable large-scale adoption of loudspeakers, complicated process, and expensive price, and achieve the effects of enhanced rigidity, simple molding process, and convenient material selection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The invention will be further described below in conjunction with specific drawings and embodiments.

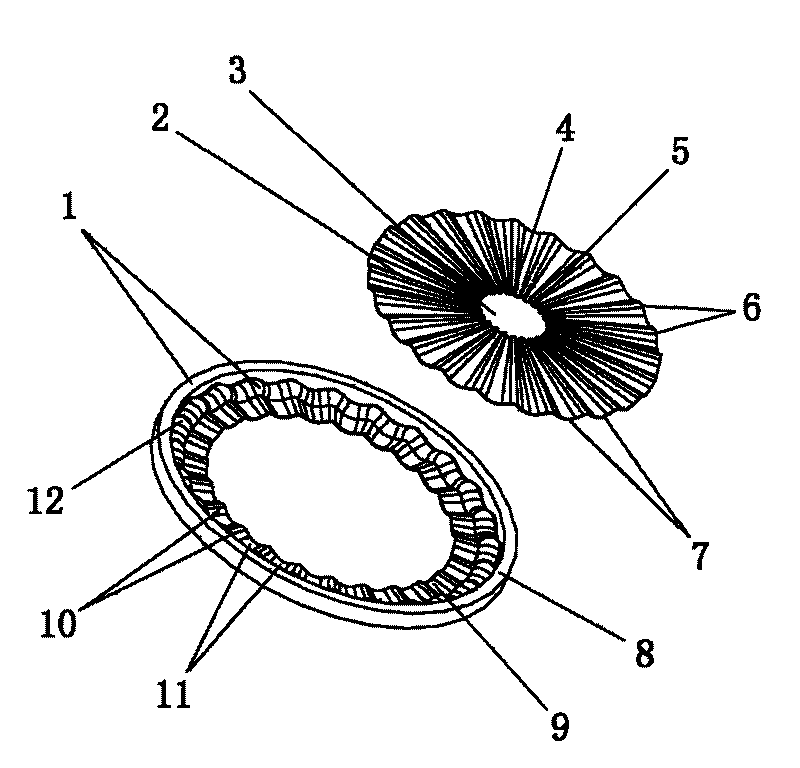

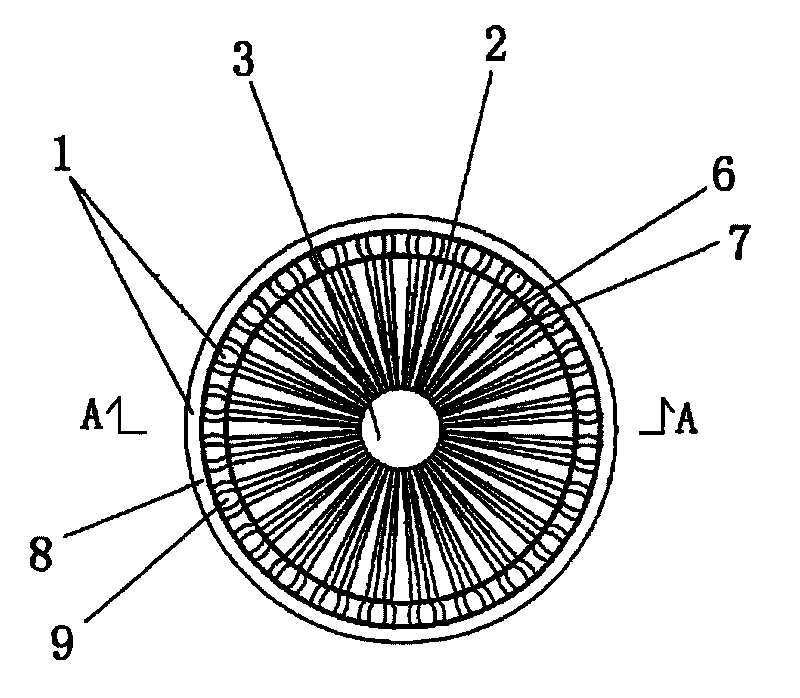

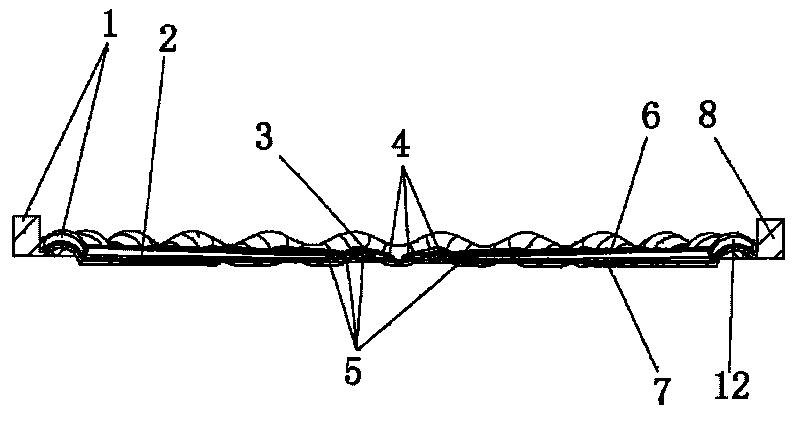

[0018] Such as Figure 1~3 As shown, the sound cone body 2 is ring-shaped and can be made of pulp material. A sound cone middle hole 3 is opened in the center of the sound cone body 2. The edge of the sound cone middle hole 3 is a wave with a middle hole wave peak 4 and a middle hole wave trough 5. shape, the middle hole wave peak 4 and the middle hole wave valley 5 are respectively extending from the center of the sound cone body 2 to the edge, forming a body wave peak surface 6 and a body wave valley surface 7 on the surface of the sound cone body 2; the body wave peak surface 6 is convex Curved surface, which extends downward to form a body trough surface 7, the body trough surface 7 is a concave curved surface, and then extends upward to form another body ridge surface 6, and so on, the body ridge surface 6 and the body trough surface 7 fluctuate and extend in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com