Train coupler uncoupling device

A technology for extractors and couplers, which is applied in the direction of railway vehicle coupling accessories, railway couplings, railway car body parts, etc., and can solve problems such as low work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

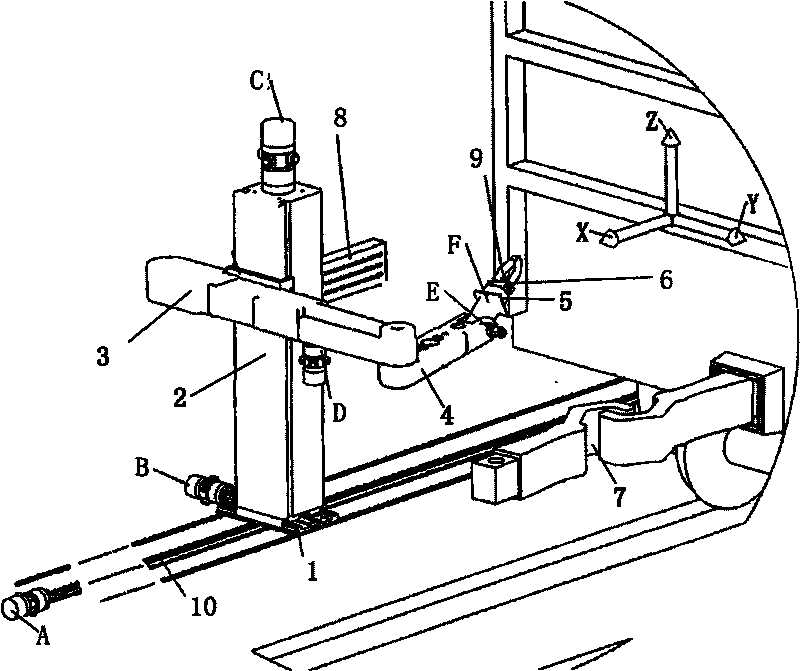

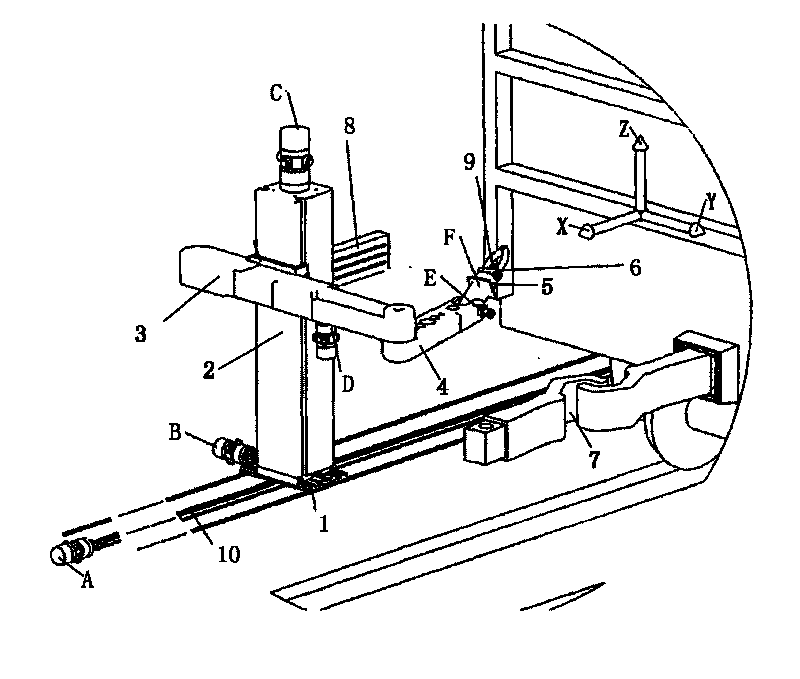

[0013] The train coupler 7 extractor is as accompanying drawing, comprises attached rail 10, slide table 1, slide post 2, big arm 3, forearm 4, wrist 5 and jaw 6, also is provided with coupler 7 position detecting devices, range finder, Coupler 7 shape recognition device, wireless receiver and alarm device. Among the three-dimensional rectangular coordinate axes in the figure, the X-axis is longitudinal, that is, parallel to the rail; the Z-axis is vertical, that is, perpendicular to the ground; the Y-axis is horizontal, and is perpendicular to the X-axis and the Z-axis. Attached rail 10 is fixedly located on the side of the vehicle rail, and attached rail 10 is longitudinal. The slide table 1 is driven by a motor A to slide longitudinally along the attached rail 10 . Sliding column 2 is driven by motor B to slide laterally along slide table 1. The boom 3 is driven by the motor C to slide vertically along the sliding post 2 . The forearm 4 is articulated near the rail end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com