Clamping device for steel bar pulling-out and steel bar pulling-out method

A clamping device and clamping technology, which is applied in construction, building maintenance, building construction, etc., can solve problems that affect the construction progress and quality of the project, and the construction is abandoned halfway, so as to achieve the effect of enhancing the stability of the operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

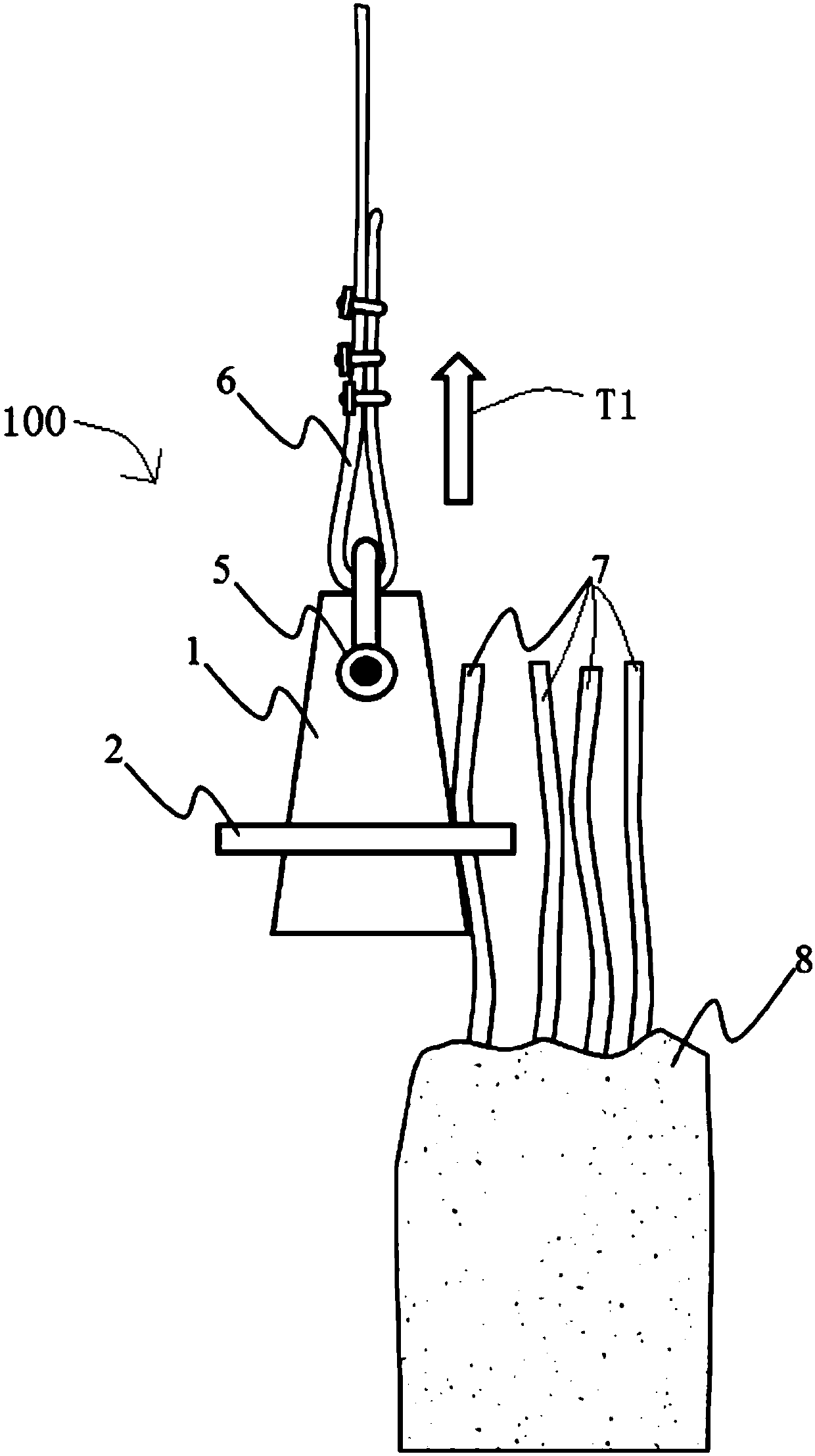

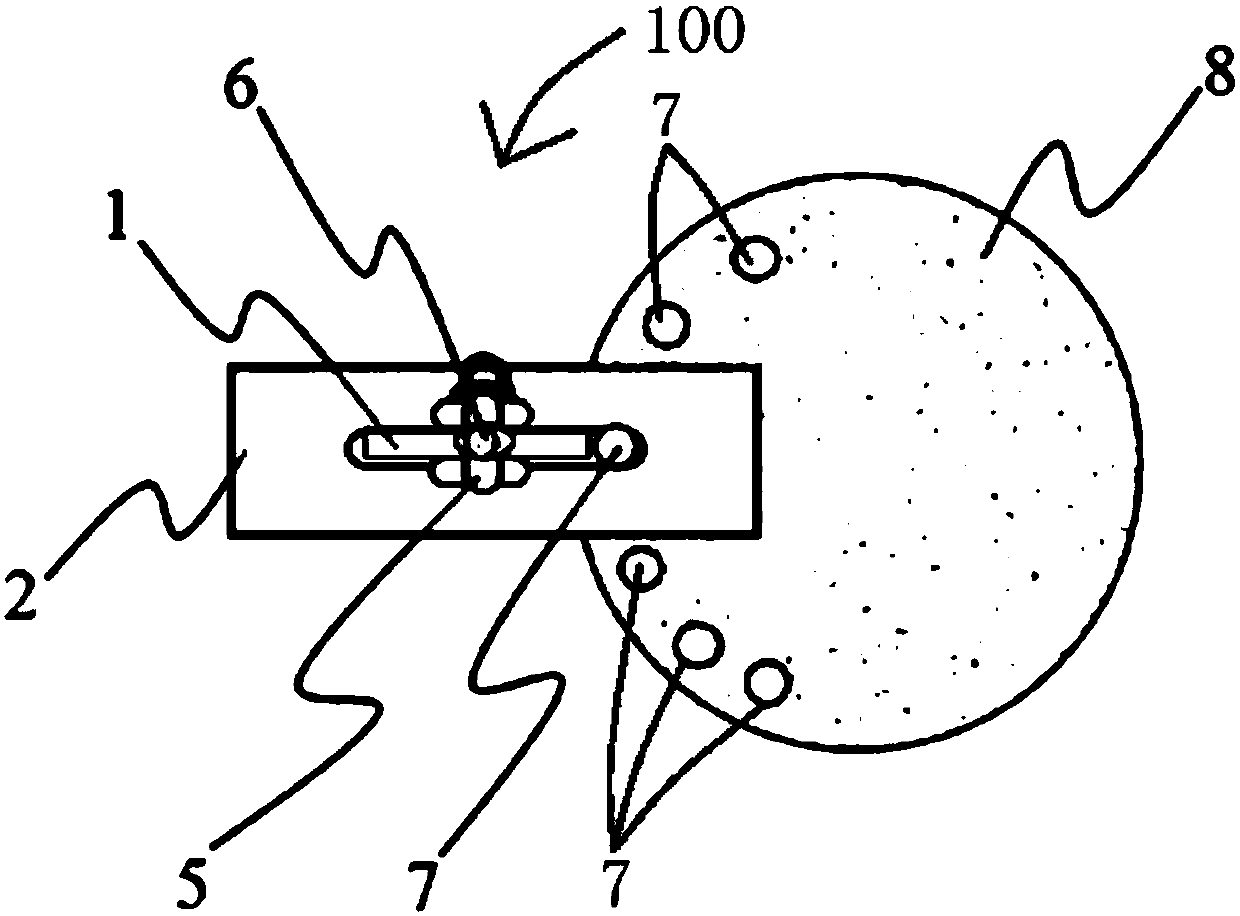

[0029] see figure 1 and figure 2 , which is a clamping device 100 for removing steel bars provided by the present invention. The clamping device 100 for removing steel bars includes a clamping part 2 and a supporting part 1 . The clamping part 2 has a clamping through hole 4 . Part of the support member 1 extends to be inserted into the clamping through hole 4 .

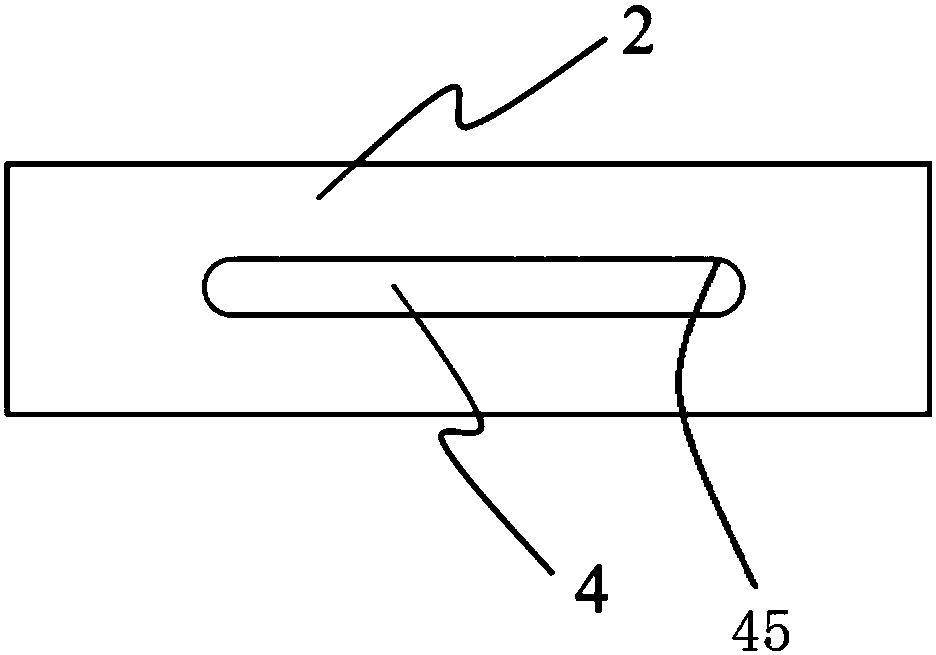

[0030] Please also refer to image 3 , the specific shape and structure of the clamping part 2 only need to be able to abut against the steel bar 7 together with the supporting part 1 . In this embodiment, for the convenience of manufacture, the clamping member 2 is a rectangular plate. In order to improve mechanical strength, the clamping member 2 is a steel plate. The specific shape and size of the clamping through hole 4 provided on the clamping member 2 can be selected according to requirements. The clamping through hole 4 is surrounded by a clamping through hole wall 45 . For the convenience of manufact...

Embodiment 2

[0036] According to needs, the connecting line between a plurality of abutting walls 15 can be set as a triangle, a quadrangle or other polygons. That is, through the cooperation of the multiple abutting walls 15 and the corresponding clamping through-hole walls 45 , multiple steel bars 7 can be clamped.

[0037] Please also refer to Figure 5 and Figure 6 , in the present embodiment, the two abutting walls 15 are arranged transversely facing away from each other, and the two corresponding steel bars 7 can be respectively abutted on the clamping through-hole wall 45 of the clamping member 2, so that Realize the clamping of two steel bars 7 at the same time. That is, if Figure 1 to Figure 3 Corresponding steel bars 7 can be clamped on both sides of the left and right sides.

[0038] The clamping device 100 for pulling out steel bars is suitable for clamping various types and shapes of steel bars 7 . In particular, when the steel bar 7 is a steel bar embedded in a buildin...

Embodiment 3

[0040] see Figure 7 , The invention provides a method for pulling out steel bars. In the method for removing steel bars, the steel bar 7 is clamped by using the clamping device 100 for removing steel bars as described above. Specifically, described steel bar extraction method comprises the following steps:

[0041]S101: Provide a clamping part 2. The clamping part 2 has a clamping through hole 4 . The clamping through hole 4 is surrounded by a clamping through hole wall 45;

[0042] S102: Make the steel bar 7 extend into the clamping through hole 4, and set up facing or in contact with the clamping through hole wall 45;

[0043] S103: Provide a support 1 . A part of the support member 1 is inserted into the clamping through hole 4 . The support 1 has an abutment wall 15 . The abutting wall 15 is made to abut against the steel bar 7 , and at the same time, the steel bar 7 is urged to abut against the clamping through-hole wall 45 .

[0044] In step S102, according to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com