A kind of belt conveyor belt replacement method

A technology for belt conveyors and replacement methods, which is applied to conveyors, hand-held tools, transportation and packaging, etc., can solve the problems of increased belt replacement time, increased volume and weight of belt replacement devices, and inability to pull, etc., to achieve High stability and safety, increased maneuverability, and guaranteed stable clamping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Below in conjunction with accompanying drawing, the present invention will be further described (hereinafter referred to as Figure 5 The left side direction is described as the front).

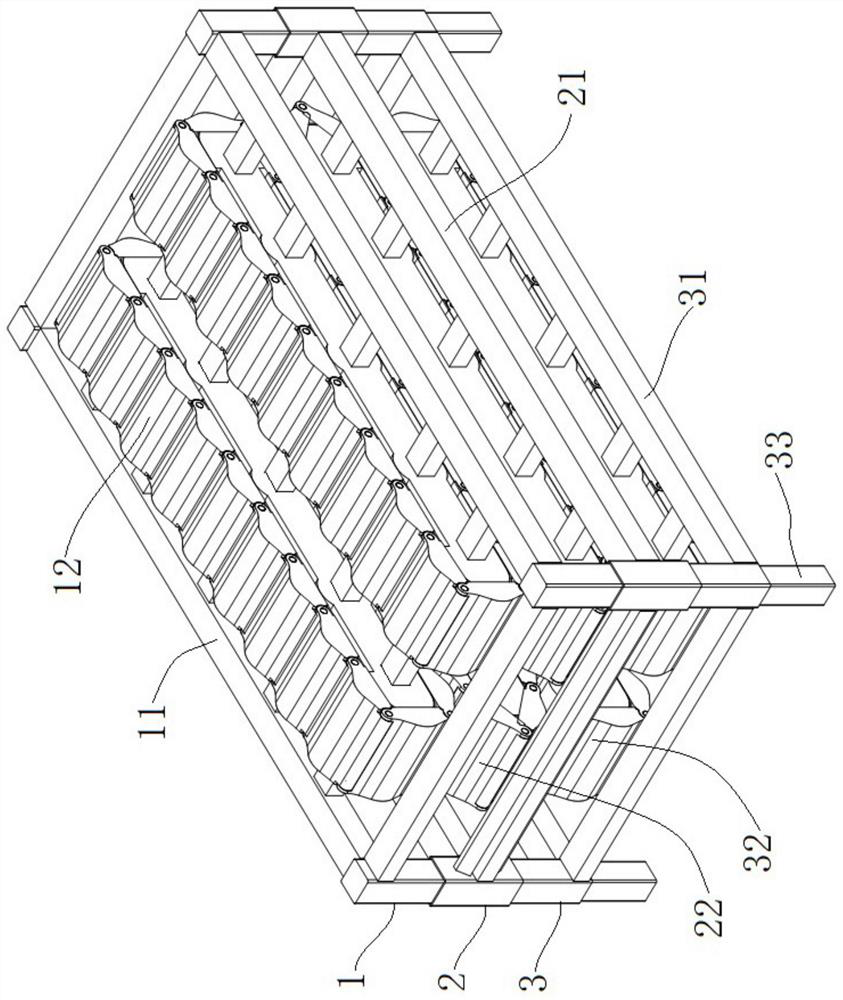

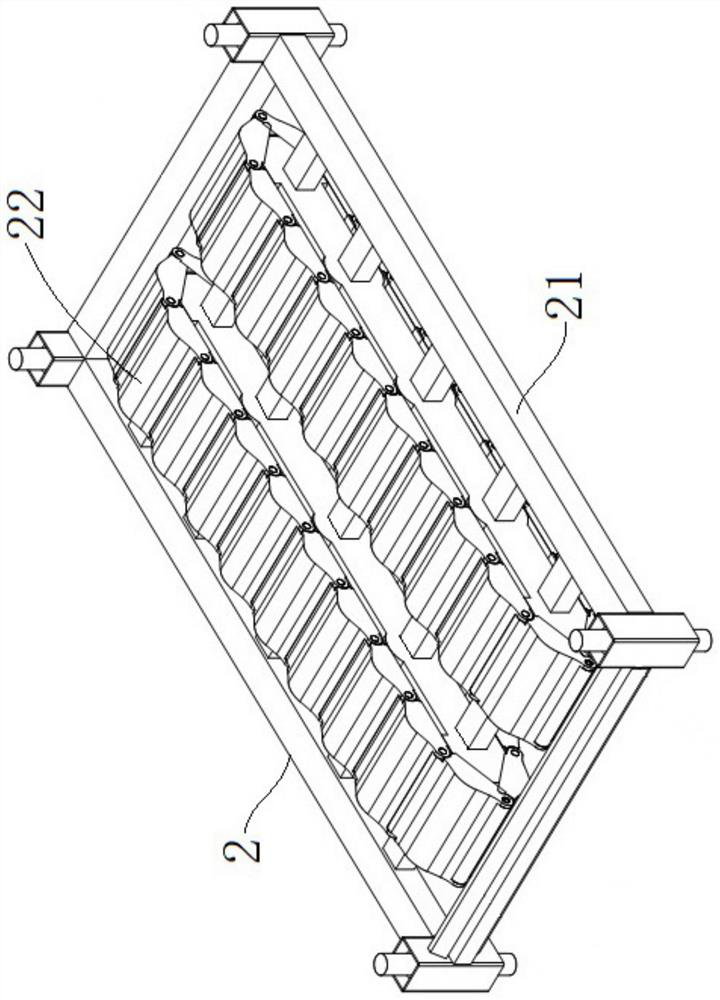

[0042] Such as figure 1 As shown, the tape replacement vehicle that can continuously and synchronously retract and release the tape includes an upper crawler part 1, a middle crawler part 2, a lower crawler part 3 and a centralized electric control part.

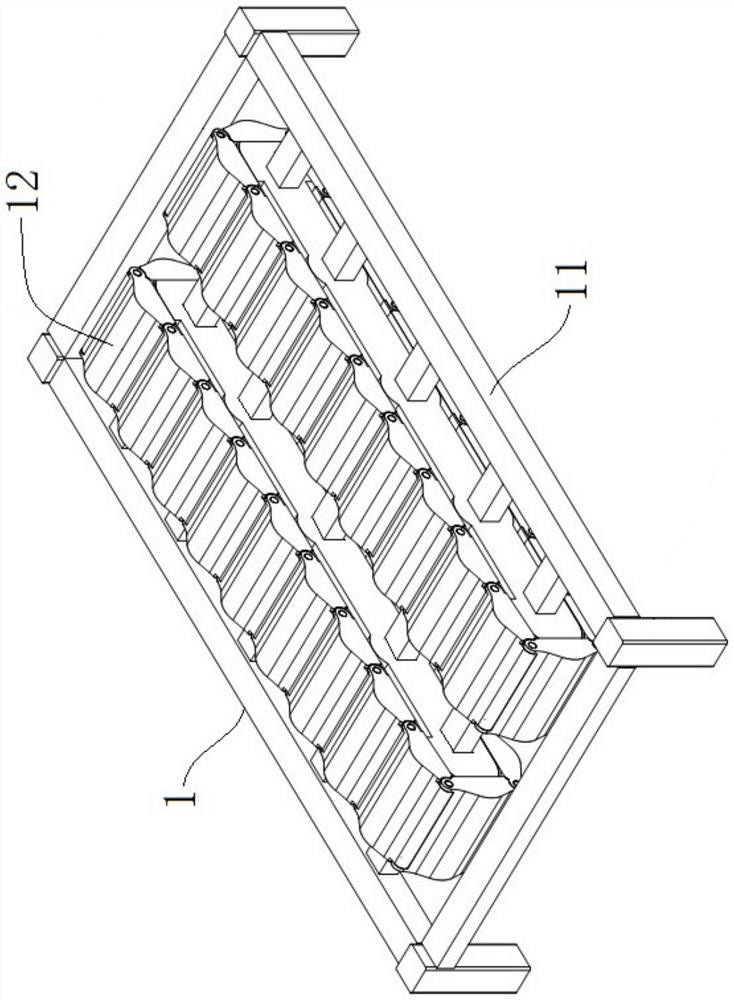

[0043] Such as figure 2 As shown, the upper crawler part 1 includes an upper crawler frame 11 and an upper crawler belt 12, and two sets of upper crawler belts 12 symmetrically arranged on the left and right are installed on the upper crawler belt frame 11 of the frame structure. Each set of upper crawler belts 12 includes The end-to-end connection of the ring-shaped track and the track drive sprocket and track support structure arranged inside the track ring structure, the track drive sprocket is arranged symmetrically in two pie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com