Device and method for detecting durability of prefabricated building sealant

A detection device and sealant technology, applied in the direction of measuring devices, weather resistance/light resistance/corrosion resistance, instruments, etc., can solve the problems of inconvenient fixing of the fixing mechanism, inability to detect the durability of the sealant, and a single detection device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

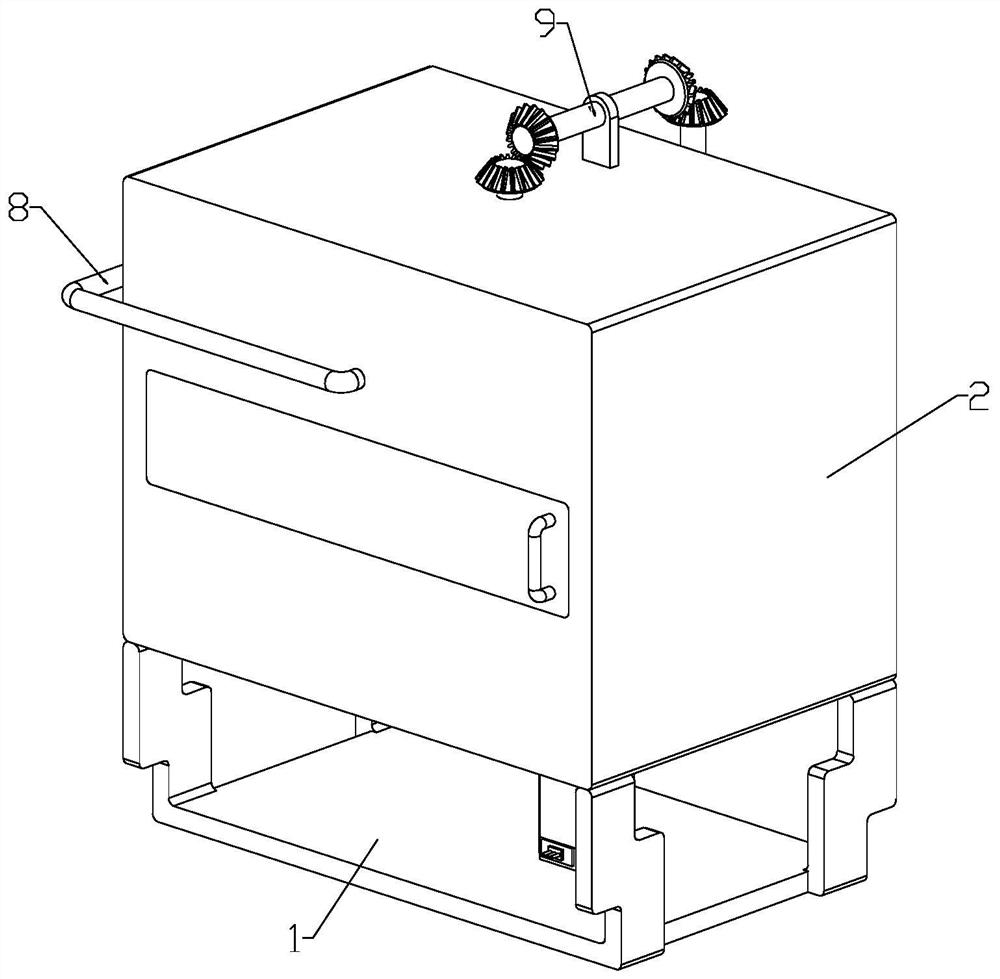

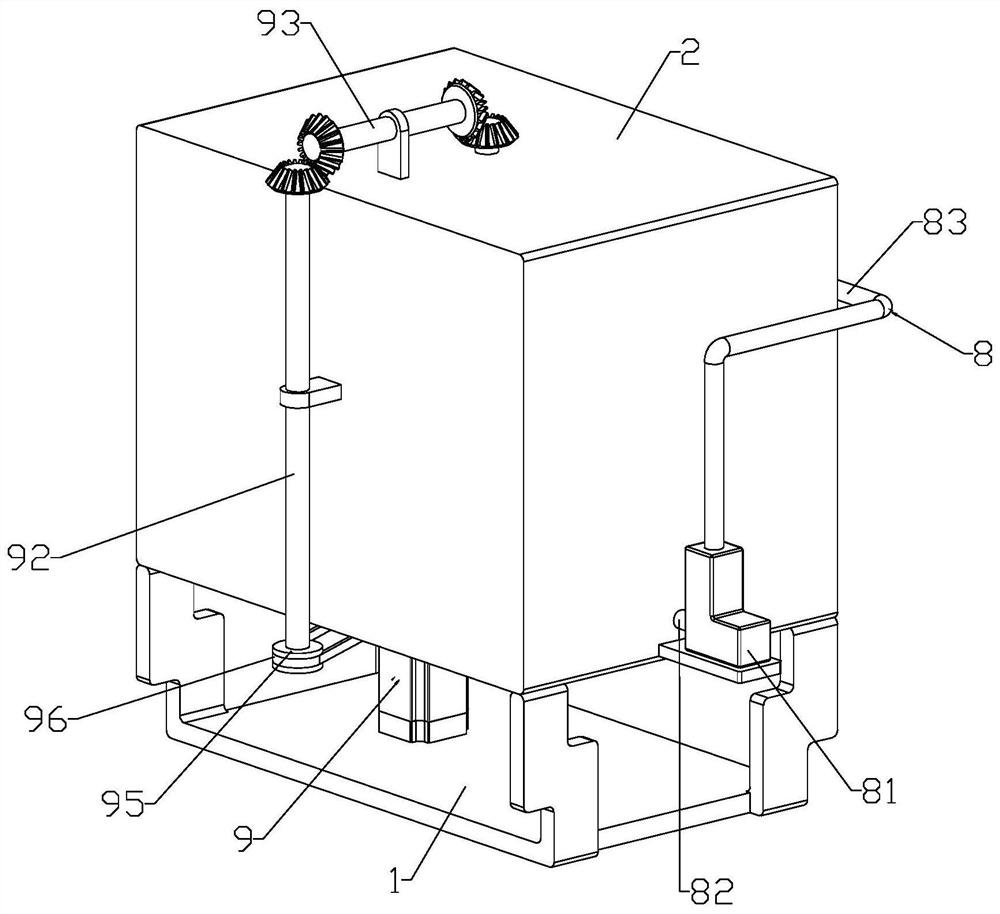

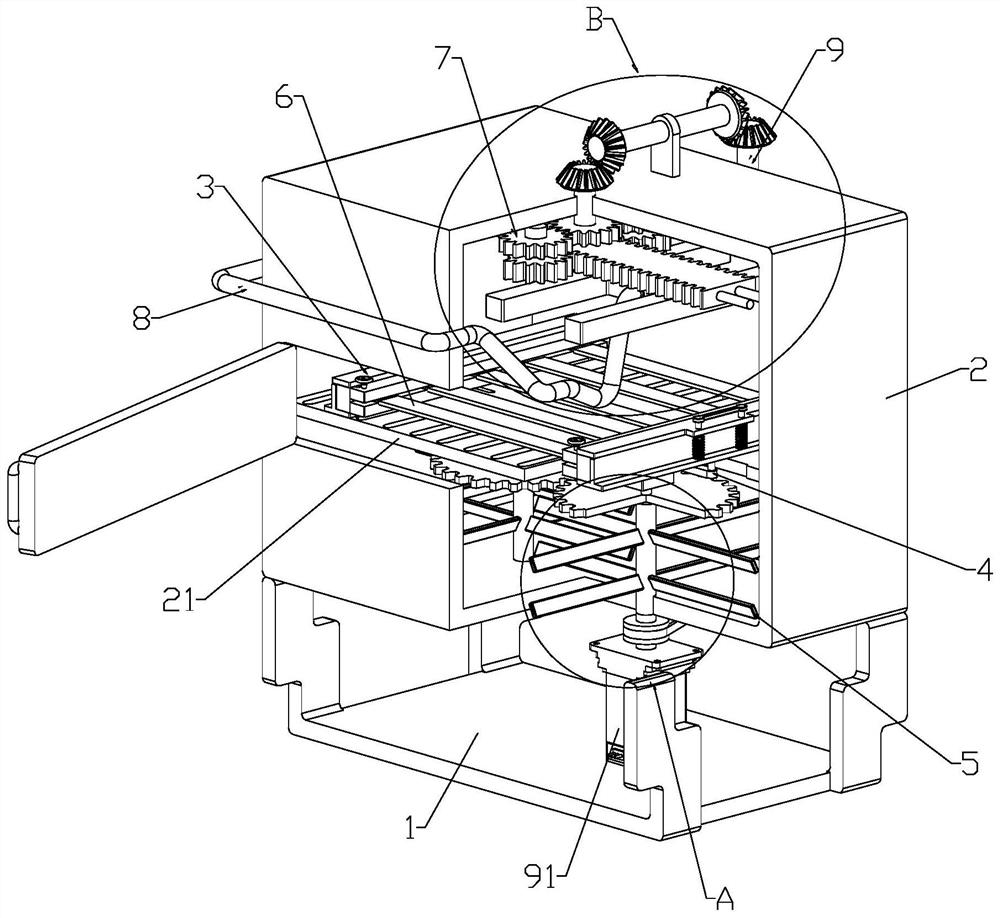

[0035] Example: such as Figure 1 to Figure 9 As shown, the present invention provides a detection device for the durability of prefabricated building sealants, comprising a support frame 1, the top of the support frame 1 is fixedly connected with a detection box 2, and the bottom end of the detection box 2 is connected with a row liquid pipe, and a valve is provided on the liquid discharge pipe, thereby providing convenience for the discharge of waste liquid, a partition 21 is fixedly installed in the inner cavity of the detection box 2, and a fixing mechanism is slidably installed on the upper end of the partition 21 3, and the lower end of the partition 21 is provided with a first reciprocating mechanism 4 used in conjunction with the fixing mechanism 3, a stirring mechanism 5 is provided between the first reciprocating mechanism 4 and the detection box 2, and the fixing mechanism 3 is detachable A sealant body 6 is provided, and a sealed door is hinged on one side of the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com