Hook removal robot with improved SCARA

A robot and improved technology, applied in railway vehicle coupling accessories, railway couplings, railway car body parts, etc., can solve problems such as low work efficiency, and achieve the effect of simple structure, flexible action, and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The purpose of the present invention will be further described in detail through specific examples below, and the examples cannot be repeated here one by one, but the implementation of the present invention is not therefore limited to the following examples.

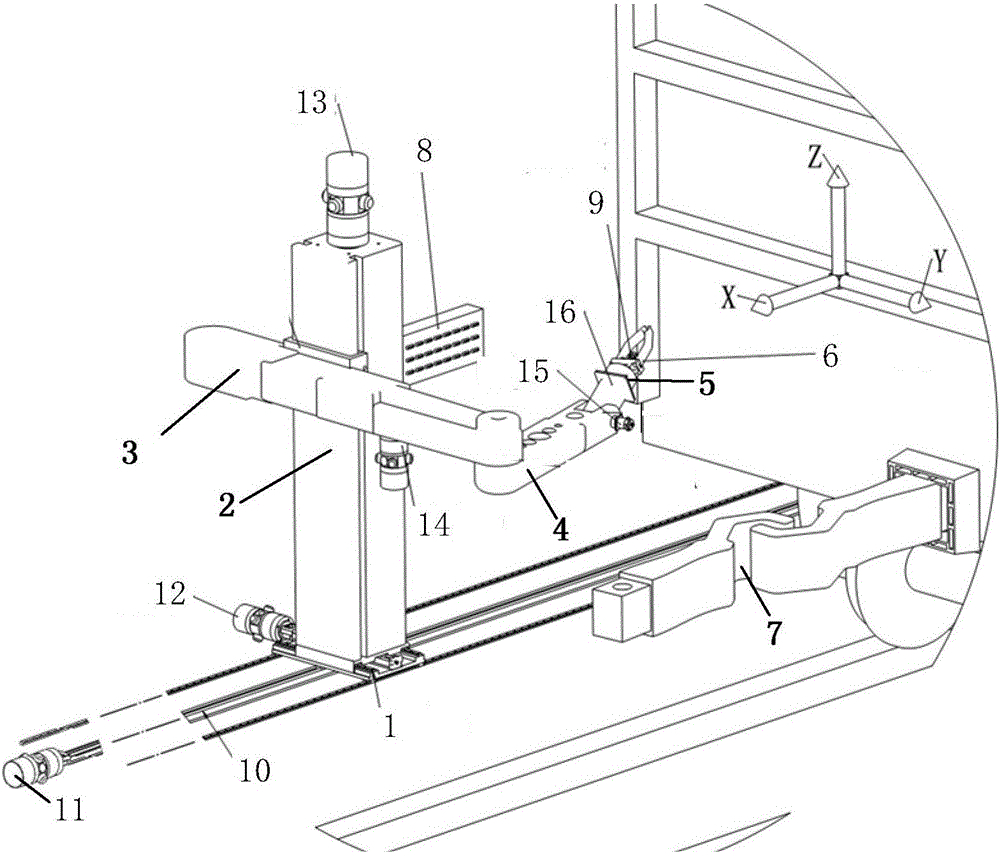

[0030] Such as figure 1 As shown, a SCARA improved coupler removal robot includes a three-axis Cartesian coordinate moving mechanism, a small arm 4, a wrist 5, a gripper 6, a coupler position detection device 8, and a coupler shape machine vision recognition device 9,

[0031] figure 1 Among the three-dimensional rectangular coordinate axes in , the X-axis is longitudinal, that is, parallel to the track; the Z-axis is vertical, that is, perpendicular to the ground; the Y-axis is horizontal, and is perpendicular to the X-axis and Z-axis. The three-axis Cartesian coordinate moving mechanism is arranged in parallel on the side of the track, and specifically includes an attached rail 10, a slide table 1, a sliding co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com