Multifunctional physical model test device of horizontal well

A test device and technology for functional objects, applied in the field of multi-functional physical model test devices for horizontal wells, can solve the problems of undeveloped sand control technology, large blindness, insufficient understanding, etc., to ensure timeliness, convenient operation, and high degree of automation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

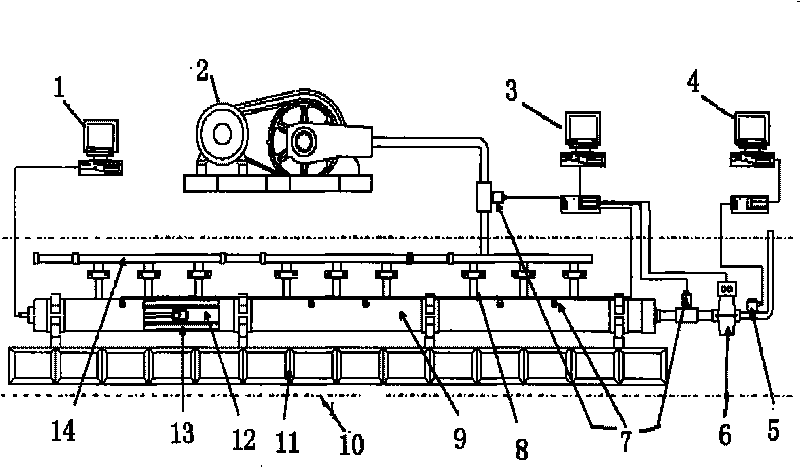

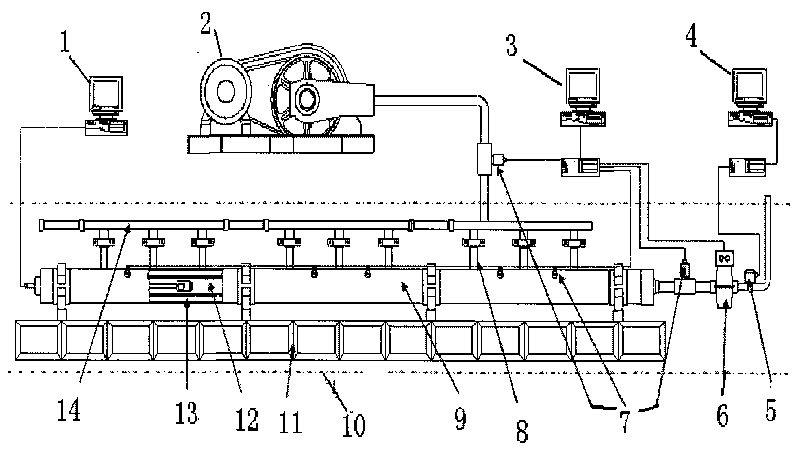

[0012] Referring to the accompanying drawings, a horizontal well multifunctional physical model test device includes a main body 10, a real-time monitoring system 1, a power system 2, a data acquisition system 3, and an on-line sand production monitoring system 4. The main body 10 has a horizontal structure, and is electrically connected to and controlled by the real-time monitoring system 1, the data acquisition system 2 and the online monitoring system 3 respectively. The main body 10 is connected with the power system 2 through pipelines. The main body 10 includes a bracket 11 and an outer casing 9 installed on it, a sand filter pipe 12 and a camera 13 installed in the outer casing 9, a formation group box 8 installed on the outer upper part of the outer casing 9, a shunt pipe 14, and a pressure sensor 7. Meter 6 and sand content sensor 5.

[0013] The real-time monitoring system 1 is electrically connected to one end of the main body 10 , and the other end of the main bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com