Plate-fin heat exchanger

A technology of plate-fin heat exchanger and fin heat exchanger, applied in the direction of heat exchanger type, heat exchanger shell, indirect heat exchanger, etc., can solve the problem of reducing the heat exchange performance, internal Uneven distribution of logistics and other problems, to achieve the effect of improving heat exchange performance and improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

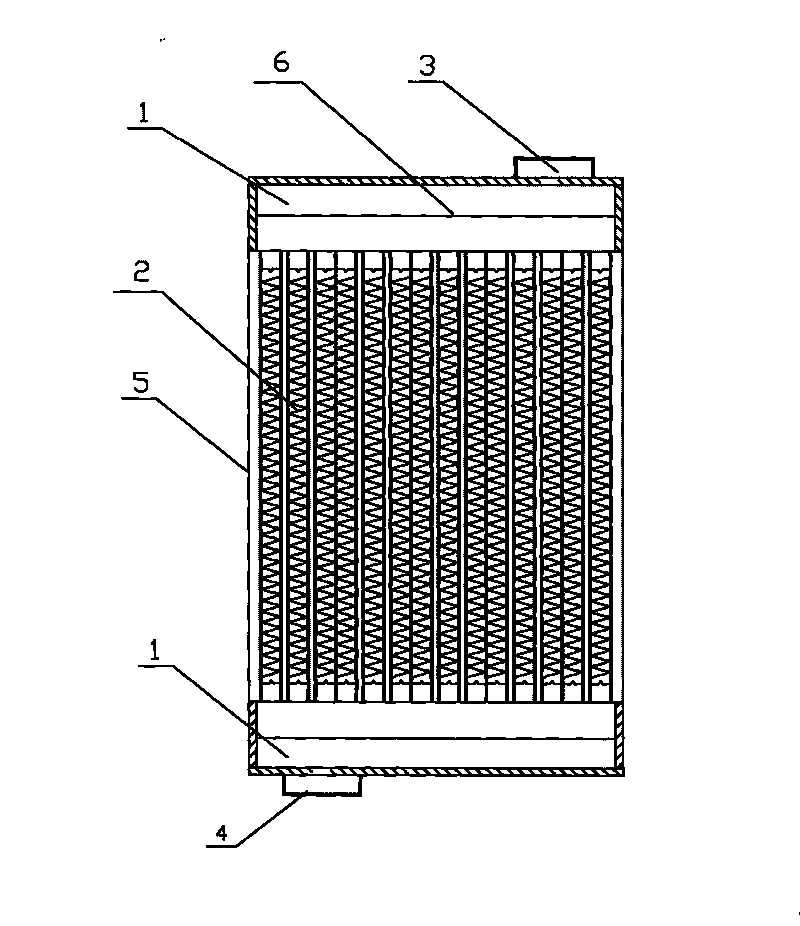

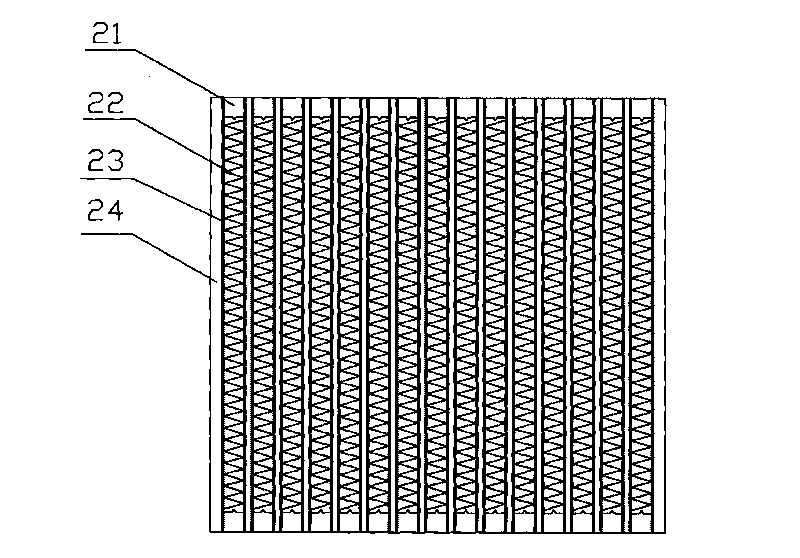

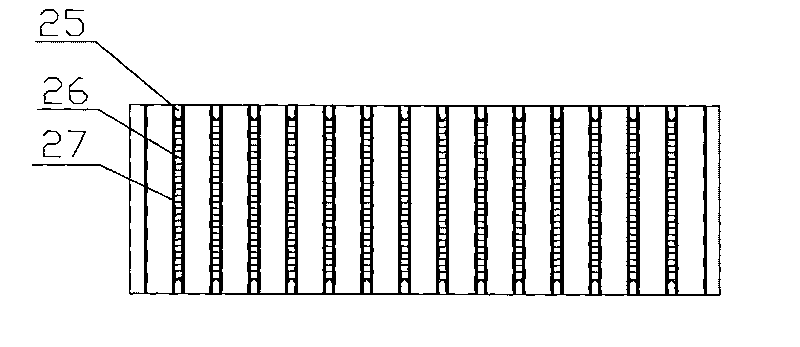

[0018] A plate-fin heat exchanger, such as figure 1 , figure 2 , image 3 and Figure 5 As shown, it includes a casing 4, a fixing part mounted on the casing 4 for fixing the plate-fin heat exchanger, a heat exchange core 2 and a head cavity 1 welded on both ends of the heat exchange core 2, the head cavity The body 1 is welded with an inlet pipe 3 and an outlet pipe 4, and the heat exchange core 2 includes an outer baffle 23, an inner baffle 27, an inner fin 26, an inner seal 25, an outer fin 22, an outer seal 21 and the sides on both sides. The plate 24, the outer fins 22 and the outer seals 21 placed between the outer partitions 23 and the outer partitions 23 form a cold channel, and the inner fins 26 and the inner seals 25 placed between the inner partitions 25 and the inner partitions 25 constitute a hot channel , the head cavity 1 is communicated with the hot aisle, the cold aisle and the hot aisle are placed in layers and crossed, the head cavity 2 has a perforated...

Embodiment 2

[0020] A plate-fin heat exchanger, such as figure 1 , figure 2 , image 3 and Figure 5 As shown, it includes a casing 4, a fixing part mounted on the casing 4 for fixing the plate-fin heat exchanger, a heat exchange core 2 and a head cavity 1 welded on both ends of the heat exchange core 2, the head cavity The body 1 is welded with an inlet pipe 3 and an outlet pipe 4, and the heat exchange core 2 includes an outer baffle 23, an inner baffle 27, an inner fin 26, an inner seal 25, an outer fin 22, an outer seal 21 and the sides on both sides. The plate 24, the outer fins 22 and the outer seals 21 placed between the outer partitions 23 and the outer partitions 23 form a cold channel, and the inner fins 26 and the inner seals 25 placed between the inner partitions 25 and the inner partitions 25 constitute a hot channel , the head cavity 1 is connected with the hot aisle, the cold aisle and the hot aisle are placed in layers and crossed, and a staggered row of uneven punchin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com