Direct-pass type optical fiber sealing device and method for manufacturing same

A sealing device, straight-through technology, applied in the coupling of optical waveguides, etc., can solve problems such as ineffective sealing, achieve good sealing effect and improve mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

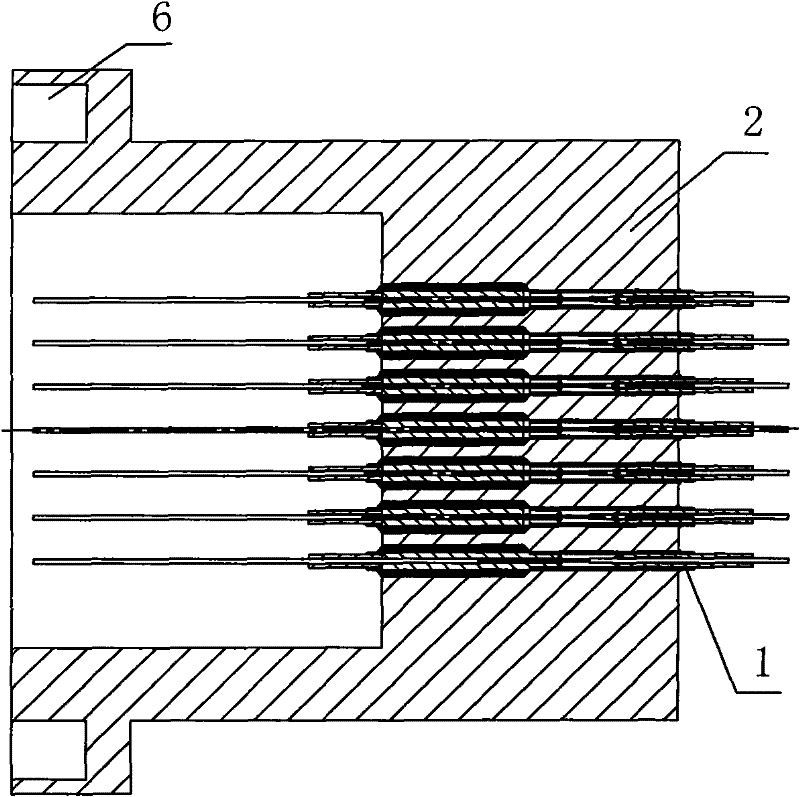

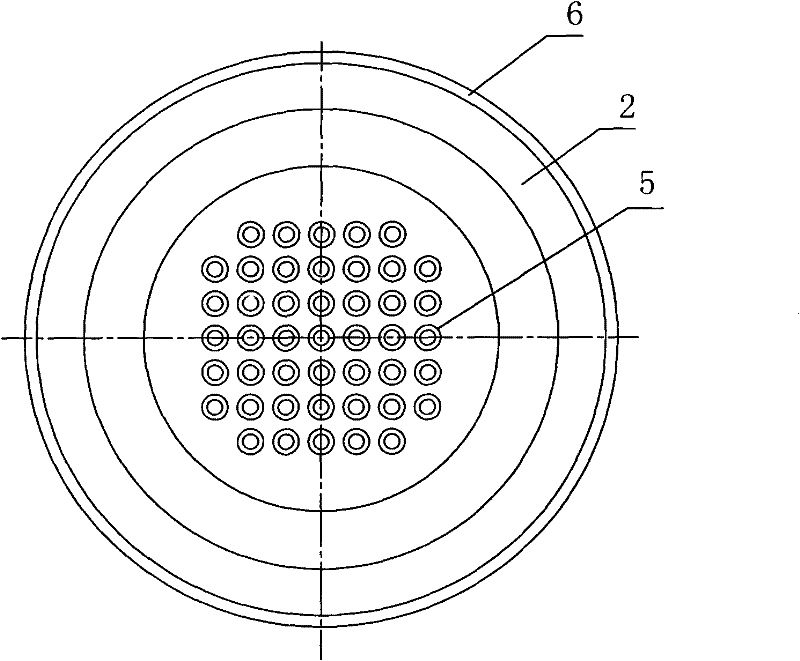

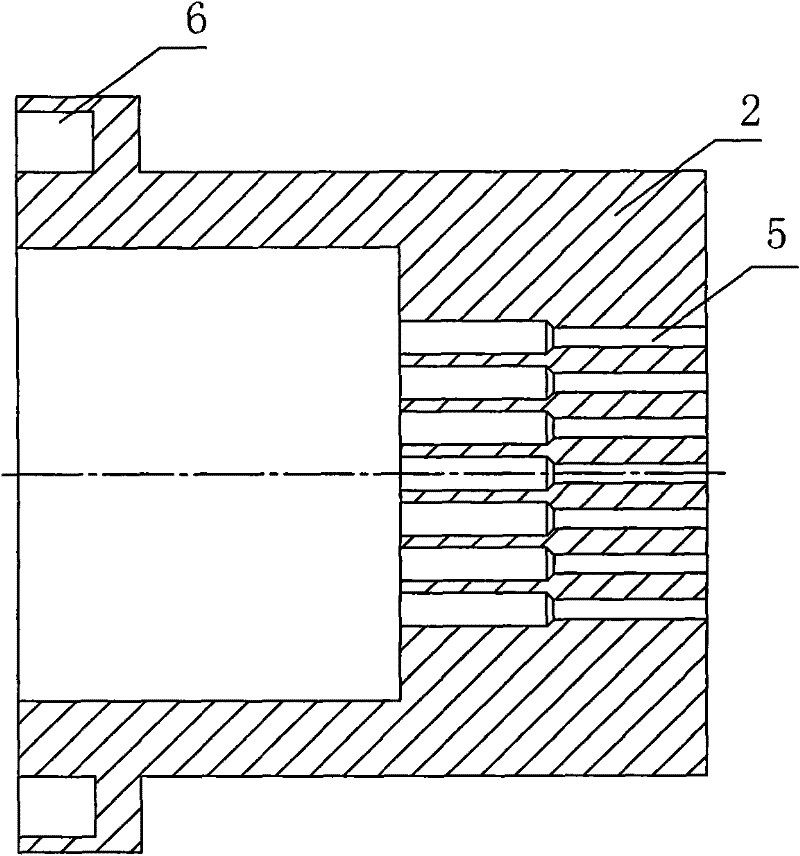

[0030] Such as Figure 1-Figure 6 As shown, a straight-through optical fiber sealing device includes a metal flange 2, and the flange 2 is provided with at least one optical fiber passing hole 5 parallel to the axial direction, and a metal tube 3 is fixed in the optical fiber passing hole 5, and the metal tube 3 is used to seal and fix the straight-through optical fiber 4 passing through it. The main sealing structure between the optical fiber passing hole 5 of the flange 2 and the metal tube 3 and between the metal tube 3 and the metallized part 10 of the straight-through optical fiber 4 are welded seal. The metal tube 3 includes a small-diameter tube 7 and a large-diameter tube 8 that are coaxially fixed together. The inner diameter of the small-diameter tube 7 matches the outer diameter of the optical fiber 4. Between 7, the filling metal solder is melted at high temperature to form a seal. The metal tube 3 also includes an optical fiber fixing tube 9 respectively fixed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com