Common motor-based low-cost energy-saving injection molding robot and control method thereof

A common motor and control method technology, applied in the direction of program control of manipulators, manipulators, manufacturing tools, etc., can solve the problems of complex process operation, cumbersome control methods, and large amount of measurement and calculation, and achieve cost reduction, low cost, and economical use line effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in conjunction with accompanying drawing.

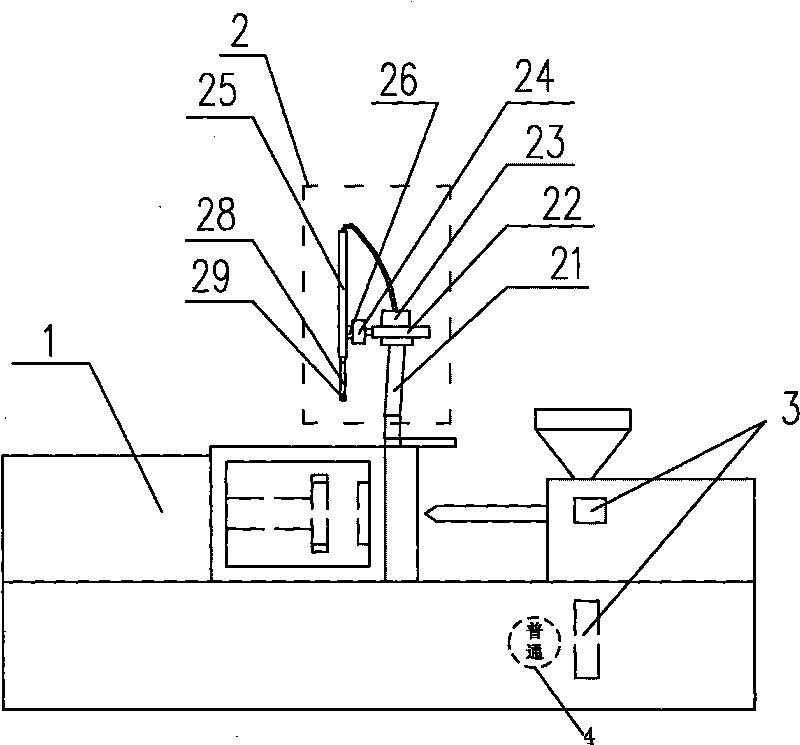

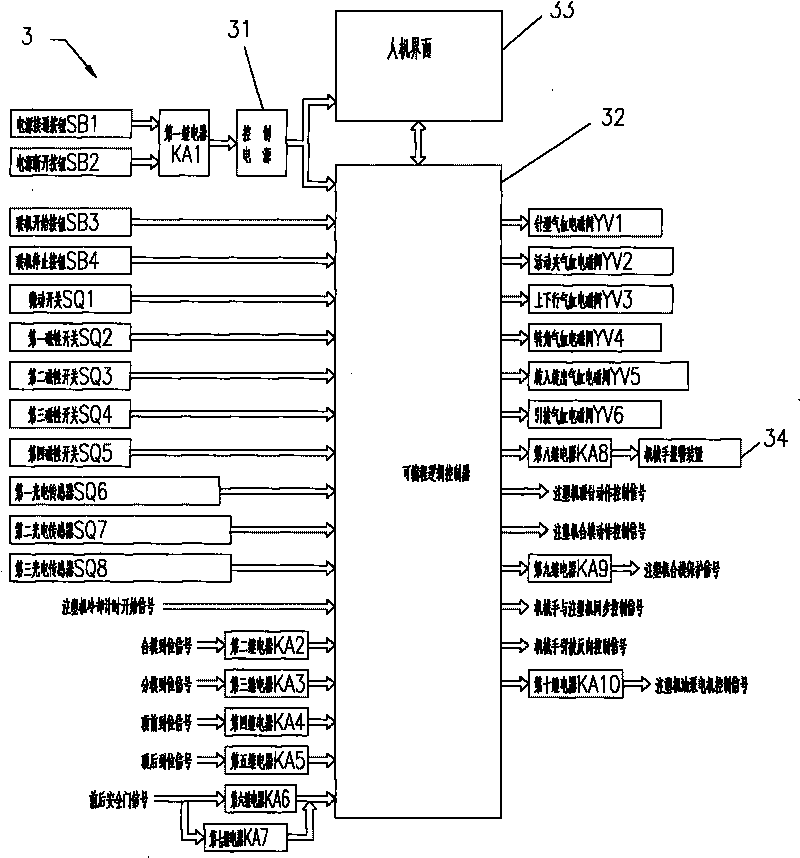

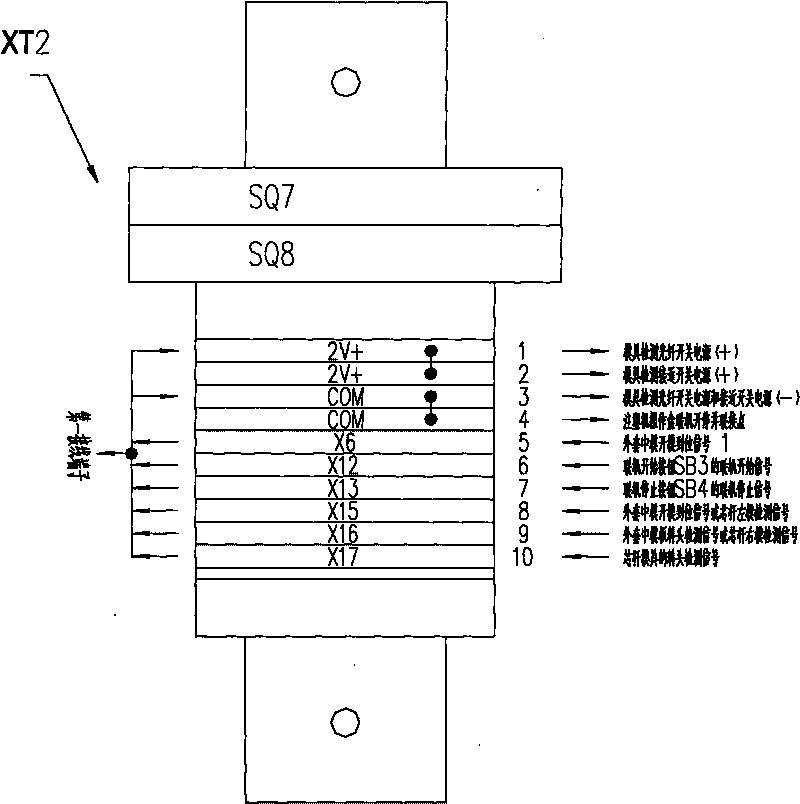

[0042] see Figure 1 to Figure 4 , the figure shows a low-cost energy-saving injection molding robot based on a common motor of the present invention, including an injection molding machine body 1, which includes an oil pump motor 4, and also includes an injection molding machine body 1. The manipulator 2, the manipulator control system 3 for controlling the manipulator 2 arranged on the injection molding machine body 1, the manipulator control system 3 sends signals through the first connection terminal (not shown in the figure) and the second connection terminal XT2 connected in series. The transmission and connection terminals are all made by WAGO Electronics Co., Ltd. (WAGO), among which:

[0043] The oil pump motor 4 in the injection molding machine body 1 adopts a three-phase common motor, and the injection molding machine body 1 in this embodiment adopts a Haida HD1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com