Device for assembling and disassembling oil pan of zero-calibration transfer printing machine

A technology of loading and unloading device and oil pan, which is used in printing presses, printing machines, general parts of printing machinery, etc. Short adjustment time and precise adjustment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

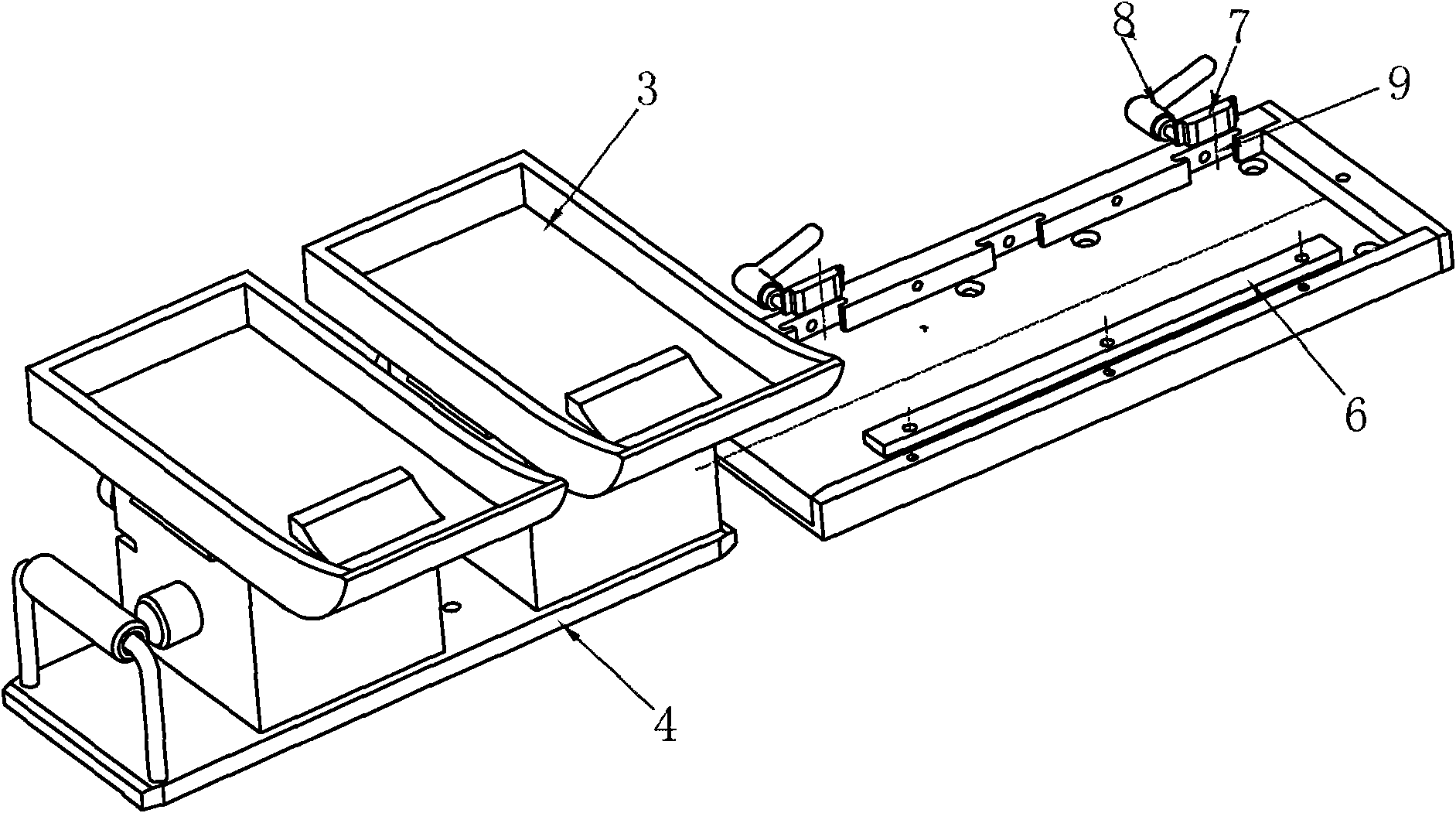

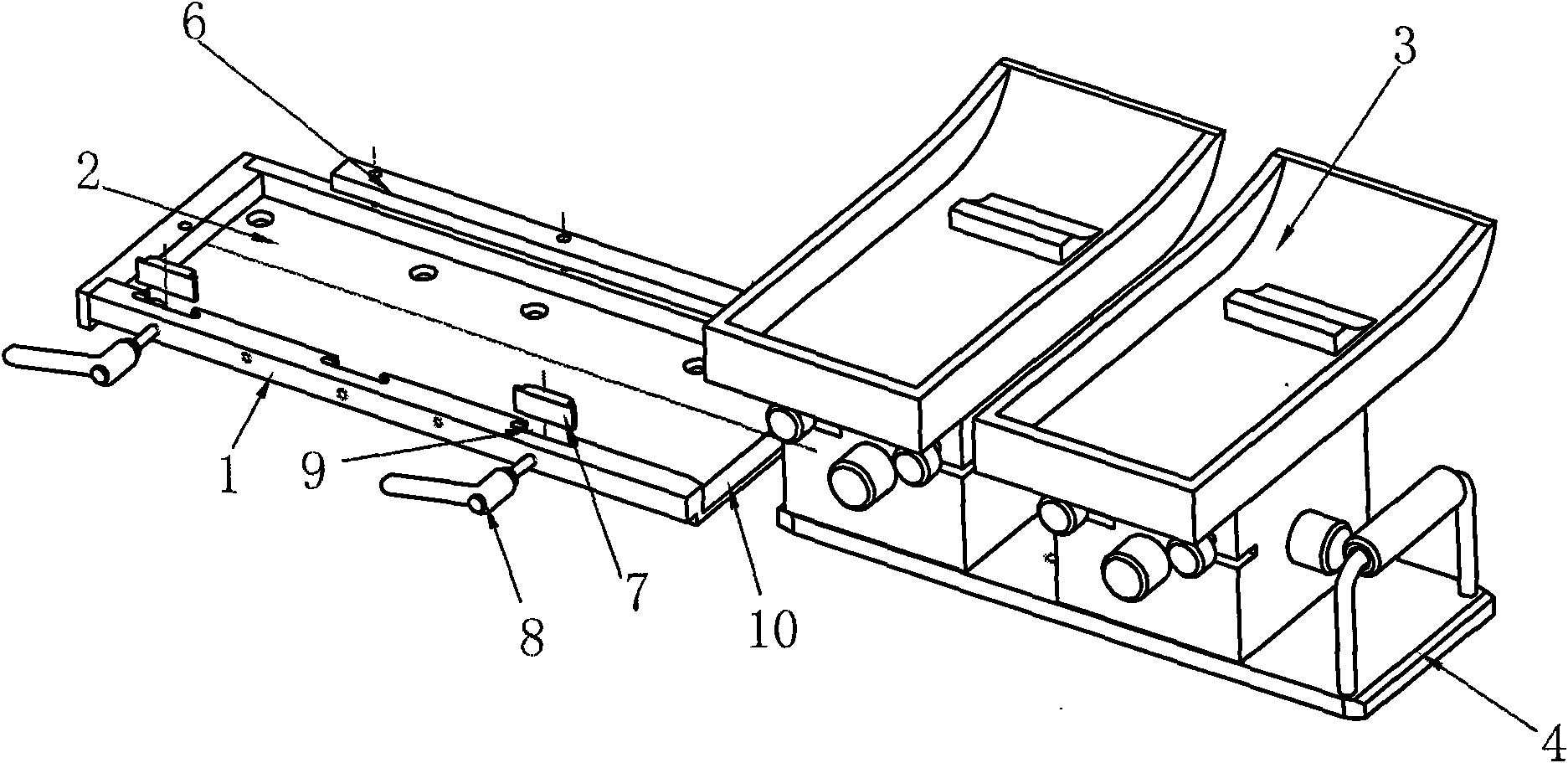

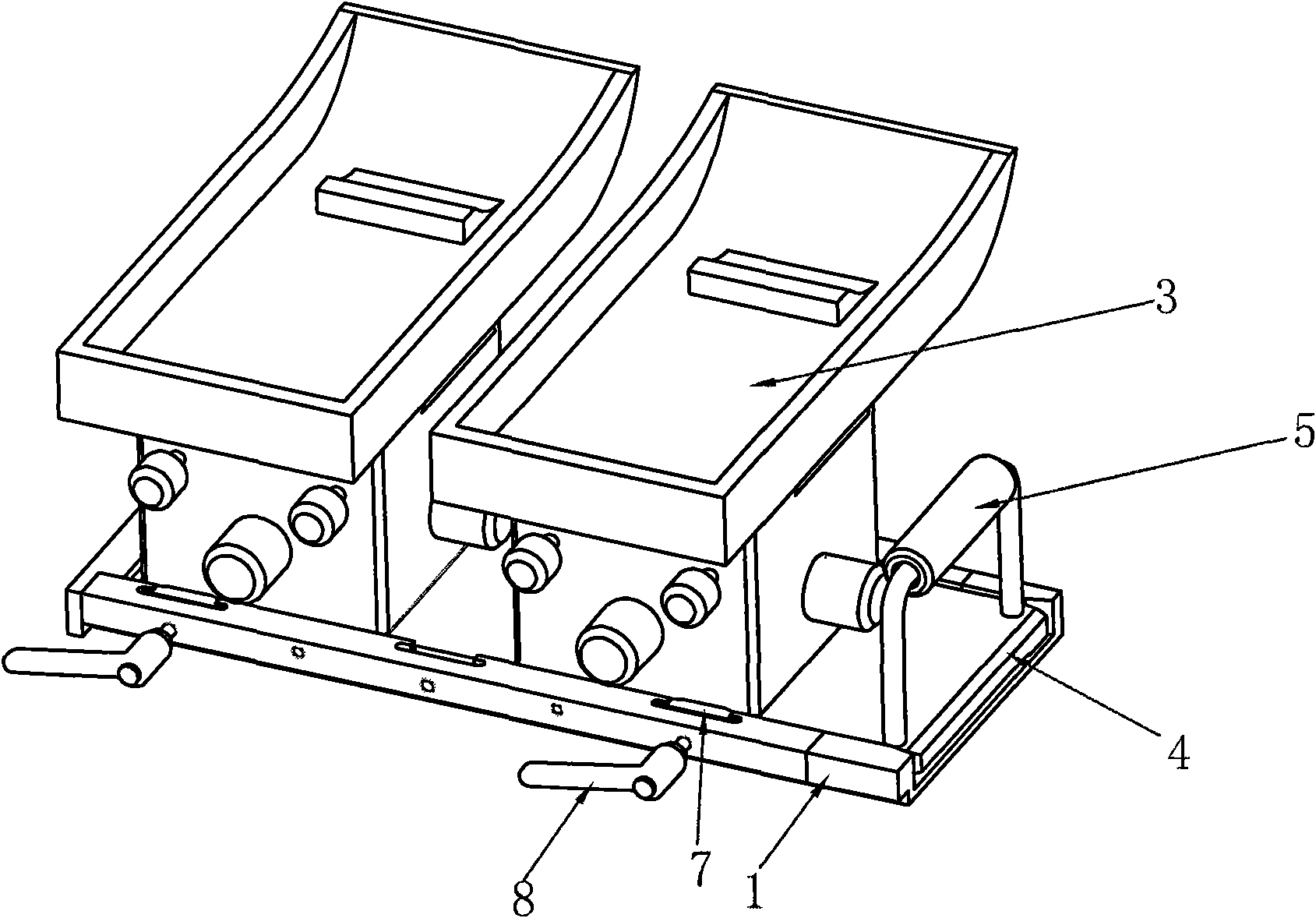

[0013] refer to figure 1 , figure 2 , image 3 , the zero-adjustment pad printing machine oil pan loading and unloading device disclosed in the present invention includes a tray 1, an oil pan positioning groove 2 is arranged on the tray 1, and the oil pan 3 of the pad printing machine can be put into the oil pan through the oil pan bottom support 4 In the positioning groove 2, an easy-to-draw frame 5 can be set on the oil pan bottom support 4. One side of the oil pan positioning groove 2 is provided with an oil pan positioning bead 6, and the side wall of the oil pan positioning groove corresponding to the oil pan positioning bead is set as a datum plane, which is used as a datum position for oil pan positioning, and is aligned with the oil pan. The other side of the oil pan positioning groove 2 opposite to the positioning bead 6 is provided with a quick locking device. The oil pan group loaded into the oil pan positioning groove 2 will be pushed tightly by the locking dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com