A multi-point temperature measurement method for converter body

A converter and body technology, applied in the field of multi-point temperature measurement of the converter body, can solve the problems of converter shutdown maintenance, uneven erosion, molten steel passing through the furnace body, etc., and achieve the effects of standardized measurement, strong timeliness and effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described now in conjunction with accompanying drawing.

[0032] The invention provides a multi-point temperature measurement method for the converter body, which solves the defects that the abnormal corrosion of the furnace lining is not easy to be found, and effective measures cannot be taken in time for maintenance; the method is easy to operate, easy to implement, and has good use effect.

[0033] The method specifically includes:

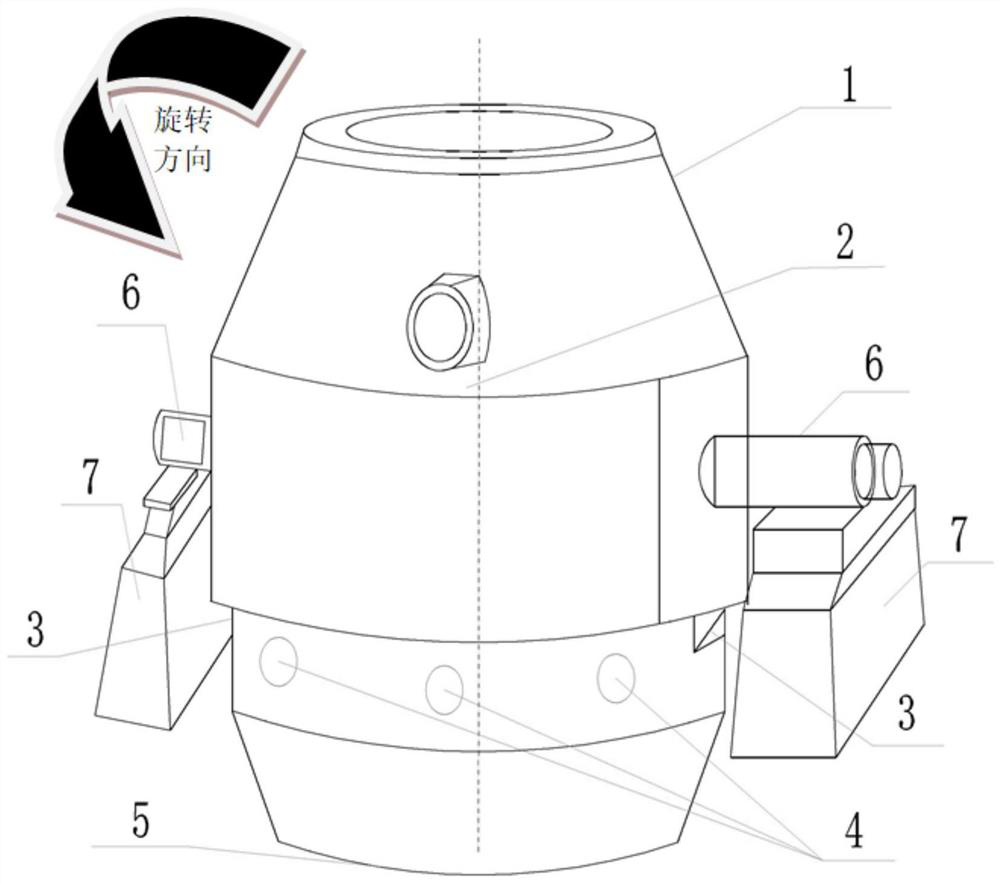

[0034] Trunnions are fixedly installed on both sides of the converter body 1, and a bearing seat 7 is installed under the trunnion 6 on each side. The trunnion 6 is installed on the bearing seat 7, and the bearing seat 7 is placed on the platform. The trunnion 6 realizes 360-degree rotation, such as figure 1 As shown in , it is assumed that the forward rotation of the converter is the positive direction, that is, the outward rotation of the vertical paper surface is the positive direction;

[0035]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com