Auxiliary manipulator for injection machine

A technology of injection machine and manipulator, applied in the field of auxiliary loading manipulator

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to enable those skilled in the art to understand the spirit of the present invention more clearly and accurately, specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

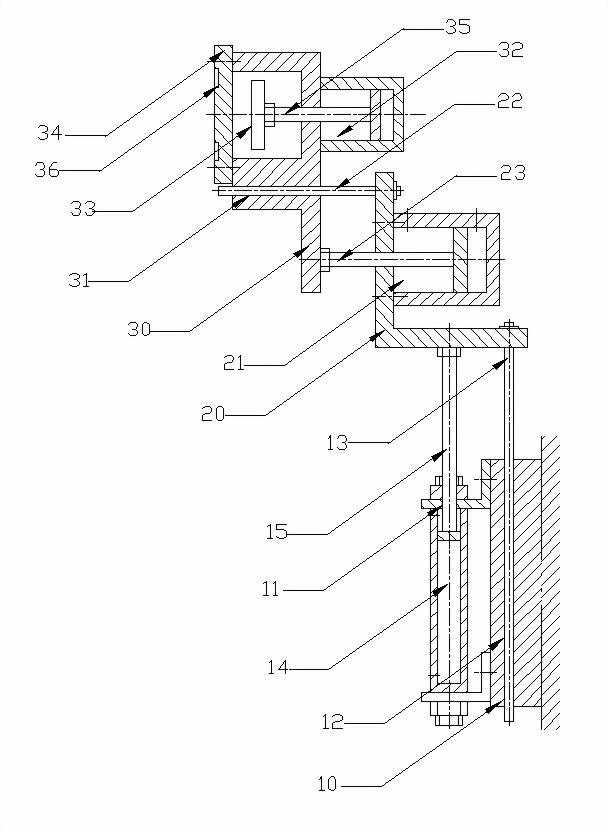

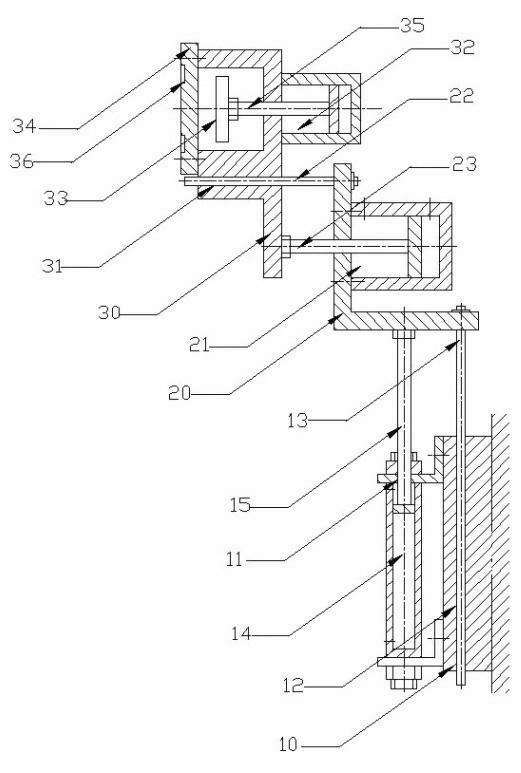

[0023] See attached figure 1 , the injection machine auxiliary manipulator according to the present invention includes: a lifting structure, an opening and closing structure, and a material loading structure;

[0024] The lifting structure includes a fixed base 10, a fixed bracket 11 fixed on the fixed base 10, and a cylinder 14 fixed on the fixed bracket 11. It is pre-set to precisely control the moving distance of the manipulator loading structure in the vertical direction.

[0025] The opening and closing structure includes a mounting seat 20 , and the mounting seat 20 is fixedly connected with the piston rod 15 of the cylinder 14 . It also includes a cylinder 21 fixed on the mounting seat 20. The function of the cyli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com